Cleaning device for removing oil stains on petroleum pipes

A technology for oil pipelines and cleaners, which is applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., which can solve problems such as difficult cleaning and blocked pipelines, and achieve extended service life, high strength and wear resistance, The effect of thorough cleaning of oil pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

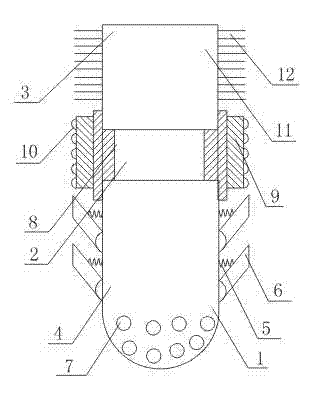

[0015] Such as figure 1 As shown, the cleaning device for removing oil stains on oil pipelines includes a scraping device 1, an edge grinding device 2, and a cleaning device 3 connected by threads in sequence from front to back; the scraping device 1, the edge grinding device 2, and the cleaning device 3 are all empty cavity structure and the inside of the scraping device 1, the edge grinding device 2, and the cleaning device 3 are connected to each other; The section is a right-angled trapezoid, one end of the spring 5 is connected to the scraper 6, and the other end is connected to the side wall of the hollow rod 4; Leak holes 7 are evenly opened on the outer wall of the hemispherical shape at the lower end; the hollow rod 4 is connected with the edging device 2 through threads.

[0016] In this embodiment, the scraping device 1 , the edge grinding device 2 and the cleaning device 3 are threaded from front to back in sequence, so that the oil stains on the oil wall pipeline...

Embodiment 2

[0018] In this embodiment, on the basis of Embodiment 1, the edging device 2 includes a grinding rod 8, a grinding layer 9 sleeved on the grinding rod 8, and a diamond grinding block 10 evenly arranged on the grinding layer 9; the grinding rod 8 The interior is provided with an internal thread, and the hollow rod 4 is fixed in the lower cavity of the grinding rod 8 through threaded connection.

[0019] After the scraper 6 preliminarily cleaned the oil pipeline, the edging device 2 in this embodiment will further clean the oil pipeline. The diamond grinding block 10 has a strong hardness and will remove the harder stains that the scraper 6 does not remove.

Embodiment 3

[0021] In this embodiment, on the basis of Embodiment 1 or Embodiment 2 or Embodiment 3, the cleaning device 3 includes a connecting rod 11 and a brush 12 evenly arranged on the outer wall of the connecting rod 11; There are external threads, and the connecting rod 11 is fixed in the upper cavity of the grinding rod 8 through threaded connection.

[0022] After the scraping device 1 and the edge grinding device 2 have cleaned the inner wall of the pipeline, the stains will be basically removed, and the brush 12 on the cleaning device 3 will brush away the remaining stains to achieve the effect of thoroughly cleaning the oil pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com