Ultrasonic grinding miniature female mold machining method based on mold dielectrophoresis effect

A processing method and a technology of dielectrophoresis, applied in the field of high-precision die processing, can solve the problems of poor processing consistency, low precision and processing efficiency, complex processing equipment and control, etc., to improve fluidity, improve processing efficiency, and increase retention. Effect of residence time and number of abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

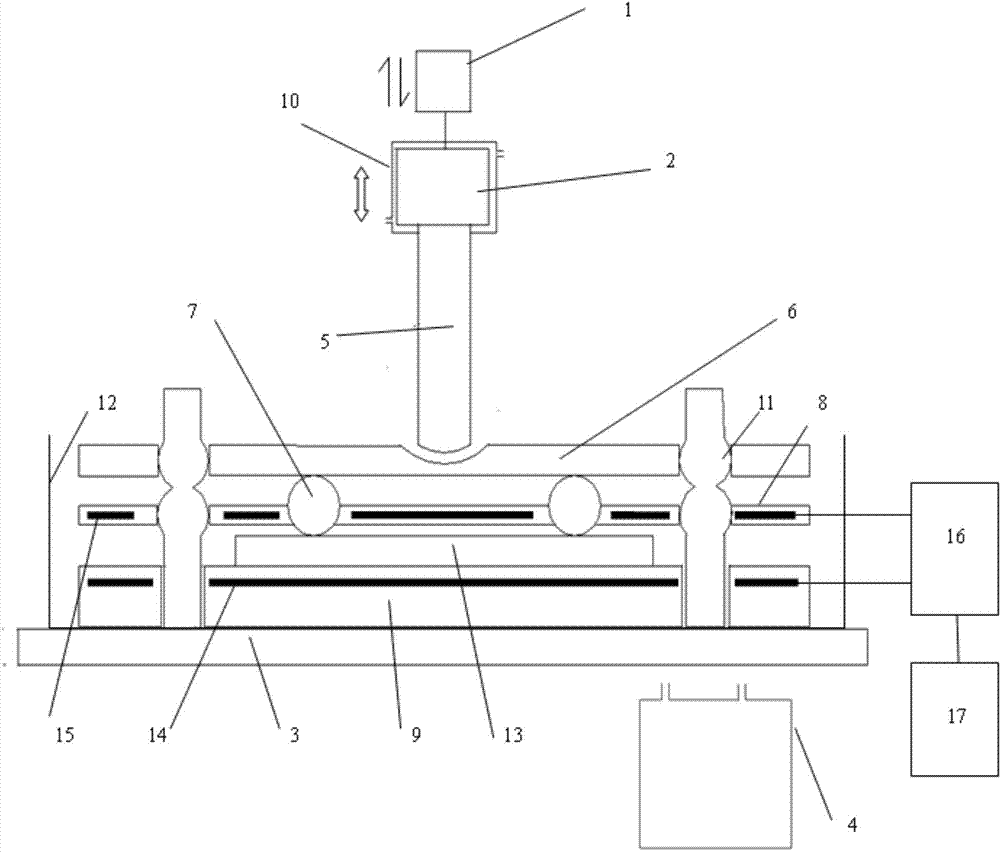

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

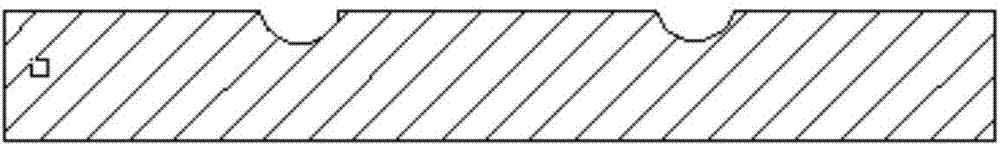

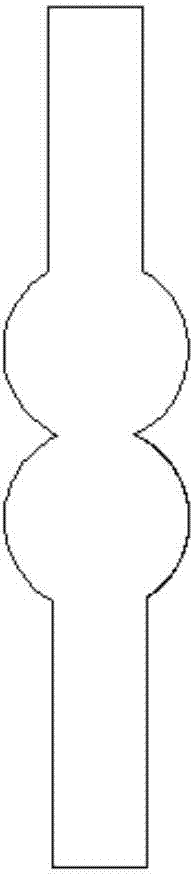

[0027] refer to figure 1~ Fig. 6, a kind of ultrasonic grinding micro-die processing method based on the dielectrophoretic effect, the processing equipment of the method includes a container 12 for storing the grinding liquid, the inner cavity bottom surface of the container 12 is a workbench 3, the A substrate 9 is fixed on the workbench 3, and a positioning plate 8 and a vibrating plate 6 are sequentially arranged above the substrate 9. A first electrode plate 14 is installed on the substrate 9, and the first electrode plate 14 is connected to an AC power supply. 16 is connected to the first lead end, and the second electrode plate 15 is installed on the positioning plate 8, and the second electrode plate is connected to the second lead end of the AC power supply 16; the current input of the AC power supply 16 The terminal is connected to the frequency modulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com