Rapid cleaning, coiling and automatic length measurement integrated device for cables

An all-in-one machine and cable technology, which is applied in the field of cable quick cleaning, cable reeling and cable length measuring all-in-one device, can solve the problems of accelerating the aging of cable insulation layer, low labor efficiency in cleaning work, and occupation of labor, etc., so as to speed up cleaning. Speed, increased service life, quick effect of recycling cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

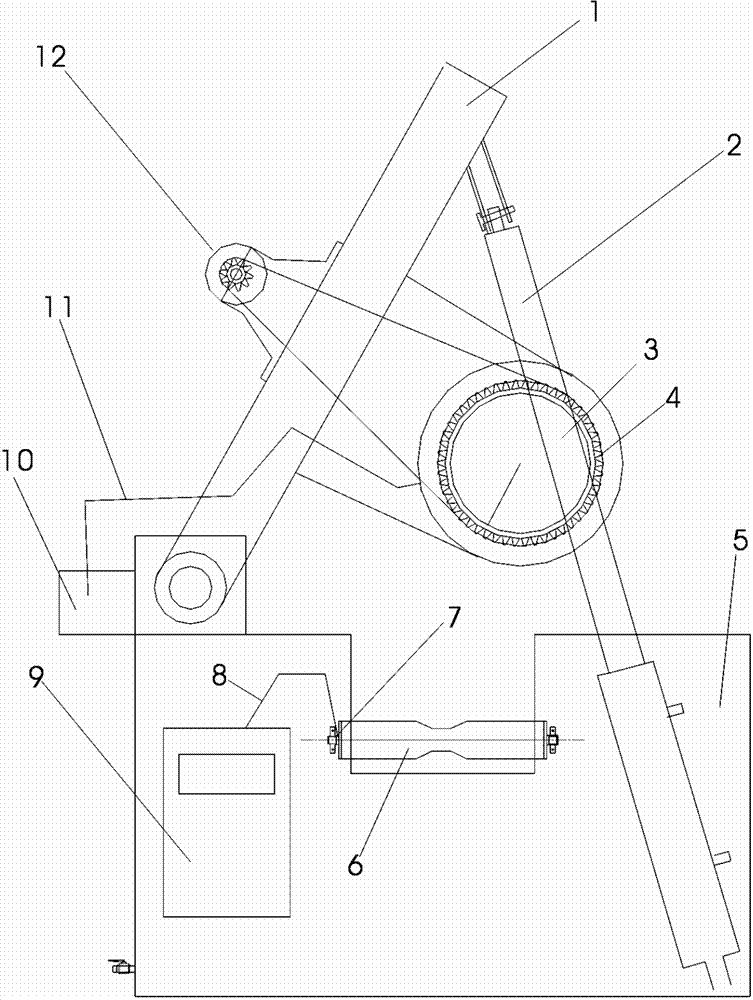

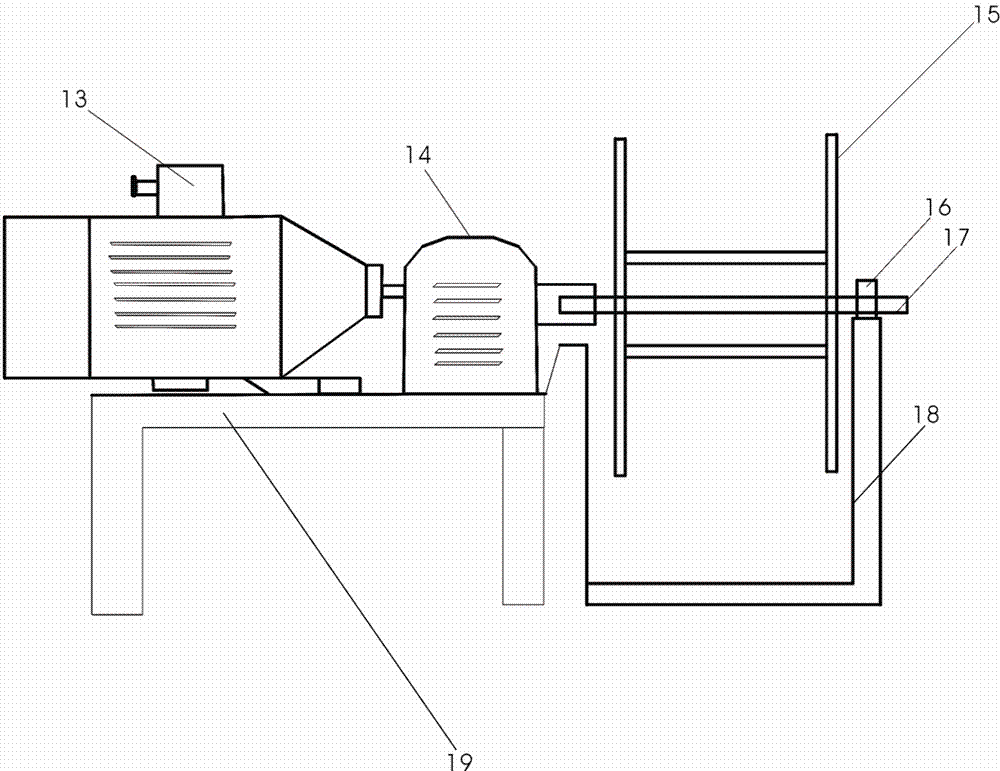

[0010] Now refer to the attached figure 1 And attached figure 2 , the description is as follows in conjunction with the embodiments: the cable quick cleaning cable reel and cable automatic length measurement integrated machine device according to the present invention includes a swing arm 1, a support cylinder 2, a driven sprocket 3, a cable cleaning hub 4, a cleaning Water tank 5, positioning length measuring roller 6, sensor 7, length measuring device connecting wire 8, numerical control length measuring display 9, soap liquid pump 10, oil pipe 11, frequency conversion speed regulating motor 12, driving motor 13, driving speed change device 14, cable roller 15. Large semicircle finale sleeve 16, reel square shaft 17, winding machine frame 18 and main body frame 19. The main body frame 19 is the grounded main part of the integrated machine device for quick cleaning of cables, cable reels, and automatic cable length measurement according to the present invention. The power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com