A new low energy consumption integrated a2/o-mbr reactor

A reactor and low-energy-consumption technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the inability to form denitrification and phosphorus removal environmental conditions, and achieve configuration and The effect of perfect combination of functions, small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

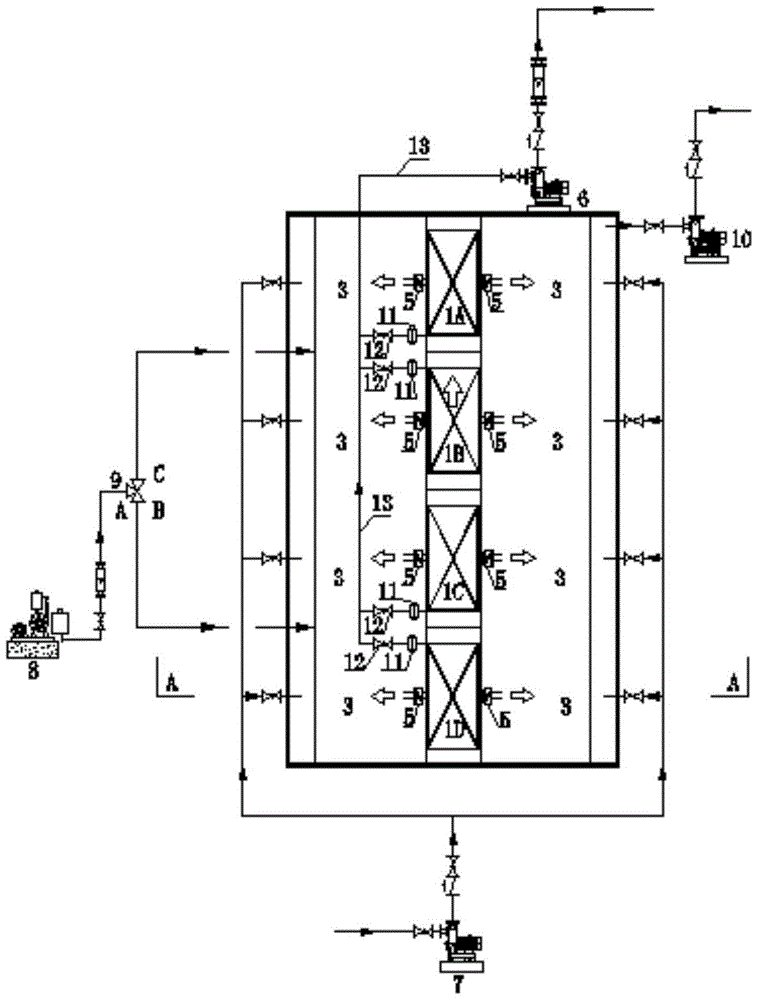

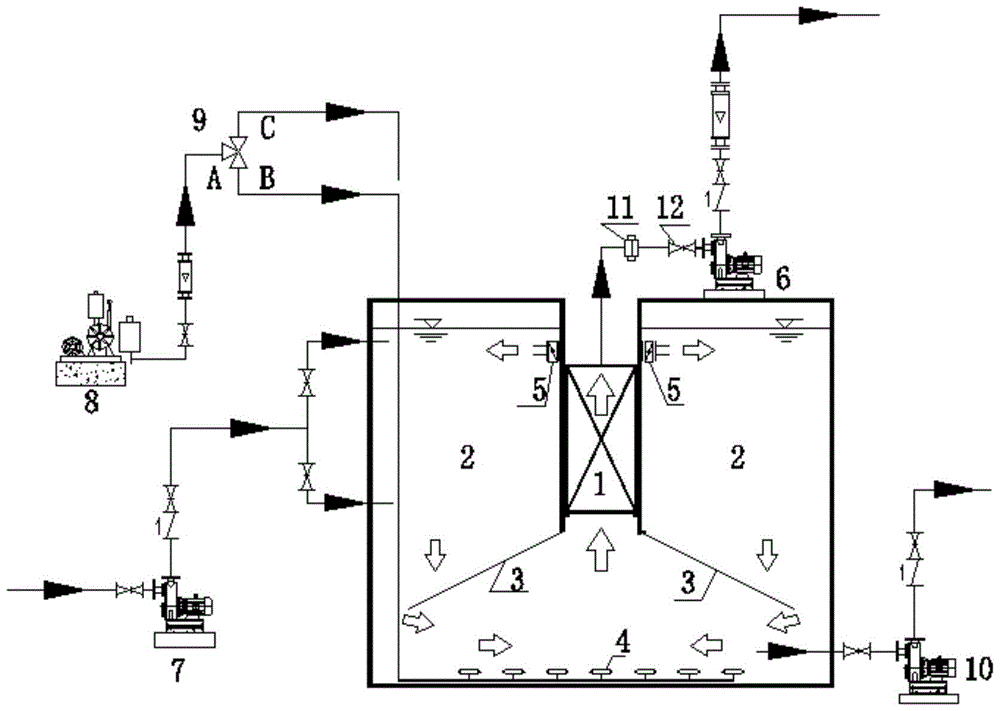

[0044] Attached below figure 2 And embodiment is described in detail, to further understand the present invention.

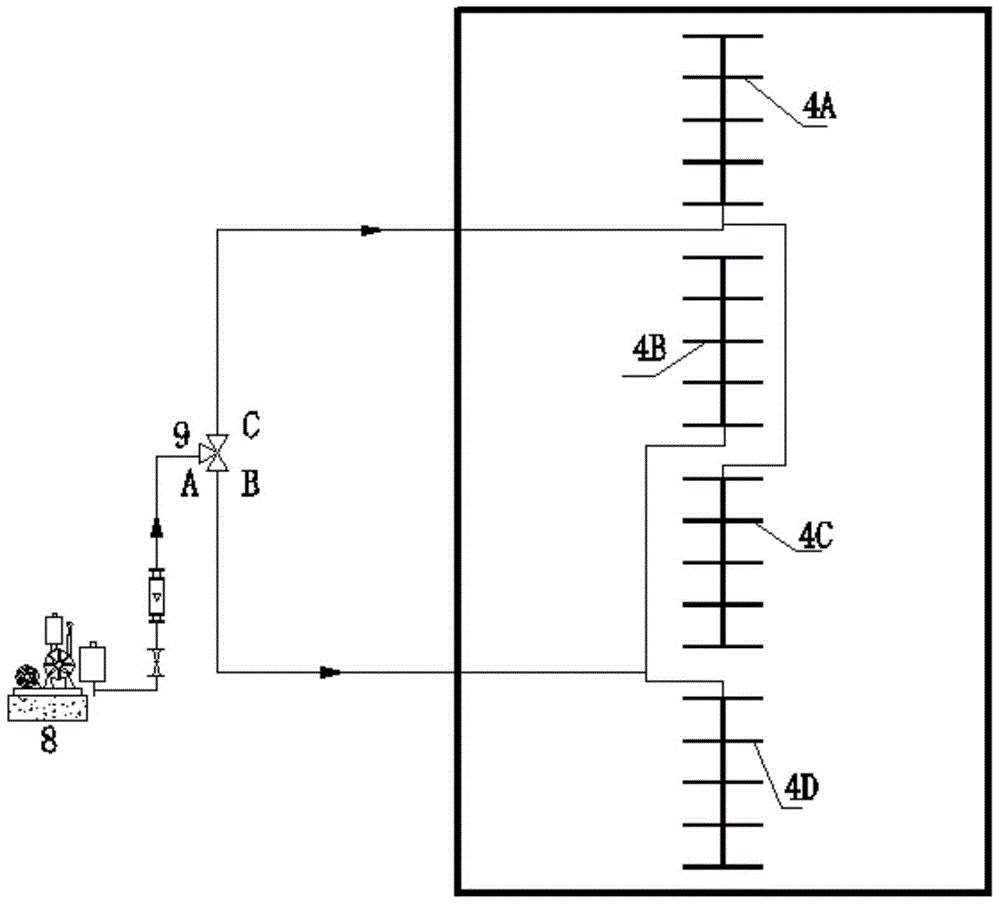

[0045] (1) Reactor assembly: After the reaction tank body is completed, an aeration device 4 is installed at a place 20-50 cm away from the bottom of the tank in the aeration area, and an aeration device 4 is installed directly below each membrane module 1, and the separated aeration device 4 is installed. After the gas device 4 is connected, the air supply main pipes of the two aeration devices are respectively connected with the B and C outlets of the electric three-way valve, and the outlet main pipe of the blower 8 is connected with the A inlet of the electric three-way valve; The gas zone is connected with the mud discharge pump 8. Two deflectors 3 are symmetrically installed on both sides of the center of the reaction pool. Install the membrane module 1 into the membrane unit area, connect its water collection pipe to the water collection main pipe 13 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com