Stage desorption and electrodeposition method for high gold and silver loaded carbon

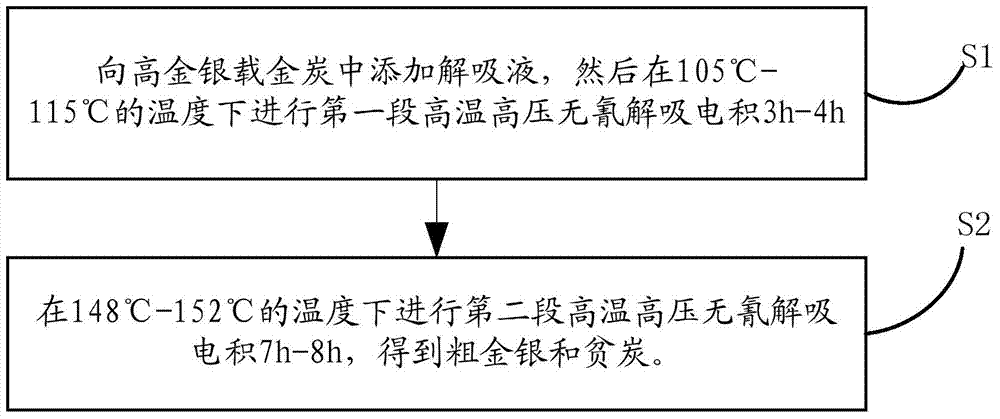

A technology of gold-loaded carbon and electrodeposition, which is applied in the field of metallurgy, can solve the problems of high gold and silver content in poor carbon, long desorption time, and large gold and silver backlog, and achieve low gold and silver content in poor carbon, short desorption time, and valuable metals. The effect of less content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The test was carried out in a high-temperature and high-pressure cyanide-free desorption device using the segmented desorption method according to the present invention. The process parameters of the first stage of desorption are: temperature is 110°C, system pressure is 0.25Mpa, desorption liquid flow rate is 4m 3 / h, the electrowinning direct current is 800A, the electrowinning cell pressure is 2.5V, the desorption time is 4 hours, and the desorption liquid is 2% NaOH solution. The process parameters of the second stage of desorption are: temperature is 148°C, system pressure is 0.45Mpa, desorption liquid flow rate is 4m 3 / h, the direct current of electrowinning is 800A, the voltage of the electrowinning tank is 2.5V, the desorption time is 7.5 hours, the desorption liquid is 2% NaOH, and the gold-containing product in the poor solution is ≤1μg / ml.

[0041] Specifically, the control of the two-stage process operation is as follows:

[0042] The first high-temperatur...

Embodiment 2

[0045] The operating method of embodiment 2 is the same as embodiment 1, and the process parameter of embodiment 2 is as follows. The process parameters of the first stage of desorption are: temperature is 115°C, system pressure is 0.25Mpa, desorption liquid flow rate is 4m 3 / h, the electrowinning direct current is 800A, the electrowinning cell pressure is 4V, the desorption time is 3 hours, and the desorption liquid is 3% NaOH solution. The process parameters of the second stage of desorption are: temperature is 152°C, system pressure is 0.45Mpa, desorption liquid flow rate is 4m 3 / h, the electrowinning direct current is 800A, the electrowinning tank pressure is 4V, the desorption time is 7 hours, the desorption liquid is 3% NaOH, and the gold-containing product in the poor solution is ≤1μg / ml.

Embodiment 3

[0047] The operating method of embodiment 3 is the same as embodiment 1, and the process parameter of embodiment 3 is as follows. The process parameters of the first stage of desorption are: the temperature is 105°C, the system pressure is 0.25Mpa, and the desorption liquid flow rate is 4m 3 / h, the electrowinning direct current is 800A, the electrowinning cell pressure is 4V, the desorption time is 3.5 hours, and the desorption liquid is 2.5% NaOH solution. The process parameters of the second stage of desorption are: temperature is 150°C, system pressure is 0.45Mpa, desorption liquid flow rate is 4m 3 / h, the electrowinning direct current is 800A, the electrowinning tank pressure is 4V, the desorption time is 8 hours, the desorption liquid is 2.5% NaOH, and the gold-containing product in the poor solution is ≤1μg / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com