Gallium arsenide polishing solution and preparation method thereof

A technology of polishing liquid and gallium arsenide, applied in the field of polishing liquid, can solve the problem of difficult to meet the polishing requirements of gallium arsenide, and achieve the effect of good use effect, guaranteeing consistency and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

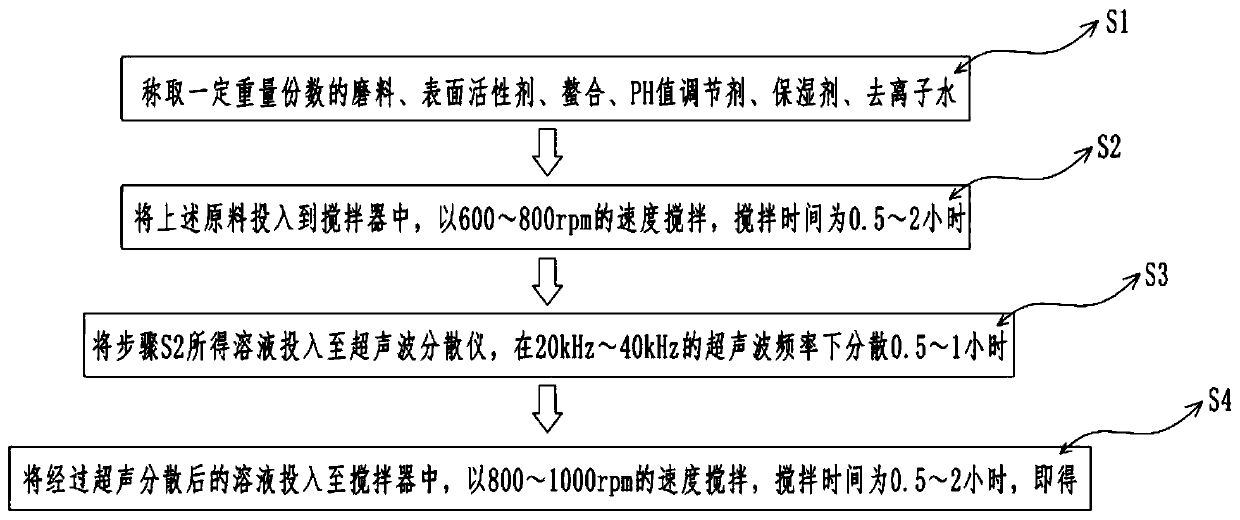

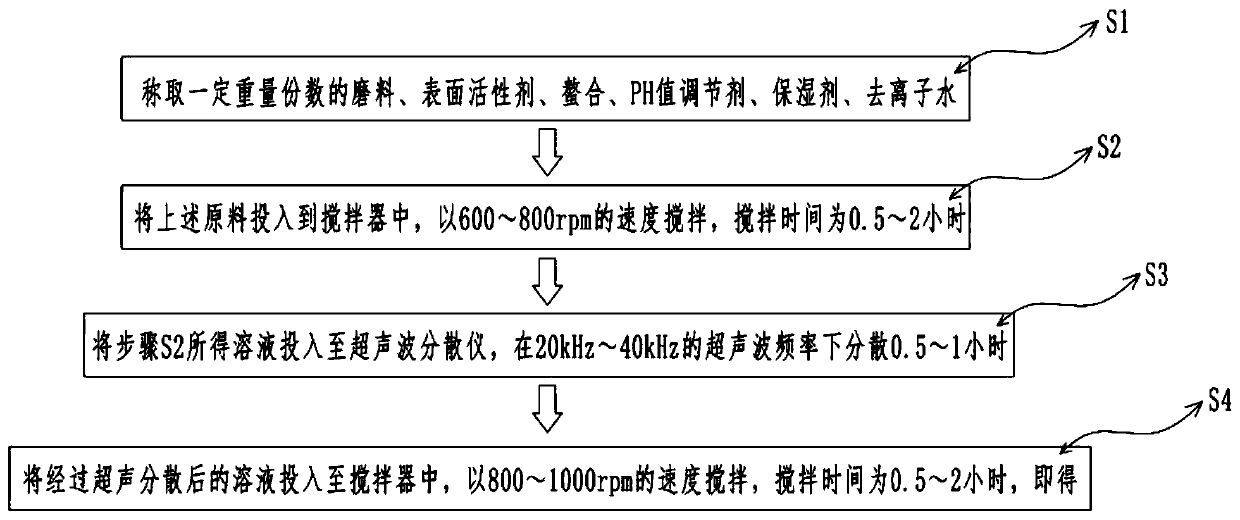

[0027] see figure 1 , in the embodiment of the present invention, a gallium arsenide polishing solution is prepared from the following raw materials in parts by weight: 20 kg of abrasive, 3 kg of surfactant, 1 kg of chelating agent, 1 kg of pH regulator, and 1 kg of moisturizing agent ㎏, deionized water 30kg.

[0028] Among the above-mentioned raw materials, the moisturizing agent is polyvinyl alcohol, the abrasive is water-soluble silica sol, the particle size is 90-150nm, the surfactant is fatty alcohol polyoxyethylene ether, the pH regulator is potassium hydroxide, and the chelating agent is ethylene glycol. The purity of amine tetraacetic acid and deionized water reaches analytical purity.

[0029] The embodiment of the present invention also provides a preparation method of gallium arsenide polishing solution, the specific steps are:

[0030] S1, weigh 20kg of water-soluble silica sol, 3kg of fatty alcohol polyoxyethylene ether, 1kg of ethylenediaminetetraacetic acid, 1...

Embodiment 2

[0035] A gallium arsenide polishing solution prepared from the following raw materials in parts by weight: 40 kg of abrasive, 7 kg of surfactant, 3 kg of chelating agent, 6 kg of pH value regulator, 3 kg of moisturizing agent, and 50 kg of deionized water . Among the above raw materials, the humectant is hydroxyethyl cellulose, the abrasive is water-soluble silica sol, the particle size is 90-150nm, the surfactant is alkanolamide, the pH regulator is sodium hydroxide, and the chelating agent is ethylene glycol. The purity of amine tetraacetic acid and deionized water reaches analytical purity.

[0036] The embodiment of the present invention also provides a preparation method of gallium arsenide polishing solution, the specific steps are:

[0037] S1, weigh 40kg of water-soluble silica sol, 7kg of alkanolamide, 3kg of ethylenediaminetetraacetic acid, 6kg of sodium hydroxide, 3kg of hydroxyethyl cellulose, and 50kg of deionized water;

[0038] S2, put 40kg of water-soluble si...

Embodiment 3

[0042] A gallium arsenide polishing solution prepared from the following raw materials in parts by weight: 30 kg of abrasive, 5 kg of surfactant, 2 kg of chelating agent, 3 kg of pH value regulator, 2 kg of moisturizing agent, and 40 kg of deionized water . Among the above-mentioned raw materials, the humectant is hydroxyethyl cellulose, the abrasive is water-soluble silica sol, the particle size is 90-150nm, the surfactant is alkanolamide, the pH regulator is sodium hydroxide, and the chelating agent is ethylene glycol. The purity of amine tetraacetic acid and deionized water reaches analytical purity.

[0043] The embodiment of the present invention also provides a preparation method of gallium arsenide polishing solution, the specific steps are:

[0044] S1, weigh 30kg of water-soluble silica sol, 5kg of alkanolamide, 2kg of ethylenediaminetetraacetic acid, 3kg of sodium hydroxide, 2kg of hydroxyethyl cellulose, and 40kg of deionized water;

[0045]S2, put 30 kg of water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com