High-strength high-toughness die-cast magnesium alloy and preparation method thereof

A high-toughness, high-strength technology, applied in the field of metal materials, can solve the problems of low mechanical properties at room temperature, low strength and plastic toughness, and the inability of strength and plastic toughness to meet the material requirements of thin-walled products, and achieve the effect of excellent casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

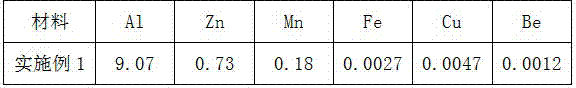

Embodiment 1

[0040] The ordinary Mg-Al series die-casting magnesium alloy (commercially available AZ91D alloy) was preheated at a temperature of 150°C~200°C for more than 60 minutes, and then placed in a protective gas SF 6 and N 2 Heat it in a melting furnace until it is completely melted, and raise the temperature of the melt to 720°C. After the AZ91D is completely melted, stir for 2 minutes until the mixture is uniform, remove the scum on the surface, let it stand for 15 minutes, cool down to below 660°C, and perform die-casting to obtain Alloy composition such as figure 1 .

[0041] The mechanical properties of the resulting alloy at room temperature are as follows:

[0042] Tensile strength UTS: 232 MPa

[0043] Yield strength YS: 135 MPa

[0044] Elongation δ: 2.3%

Embodiment 2

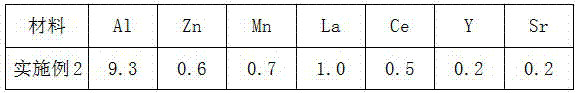

[0046] First, preheat the Mg-LaCe alloy, Mg-Y alloy and Mg-Sr alloy at 150°C~200°C for more than 60 minutes; then place the AZ91D alloy in SF with protective gas 6 and N 2 Heat it in a melting furnace until it is completely melted, raise the temperature of the melt to 720°C, and add the preheated Mg-LaCe alloy, Mg-Y alloy and Mg-Sr alloy. After fully melting, stir for 3-5min until the mixture is uniform. , remove the scum on the surface, let it cool down to below 660°C, and perform die-casting to obtain the high-strength and high-toughness die-casting magnesium alloy, such as figure 2 shown.

[0047] The mechanical properties of the resulting magnesium alloy at room temperature are as follows:

[0048] Tensile strength UTS=252 MPa

[0049] Yield strength YS= 160 MPa

[0050] Elongation δ= 3.0%

Embodiment 3

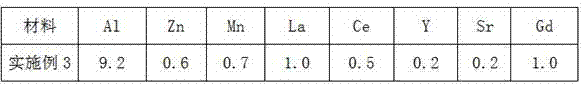

[0052] Preheat pure magnesium, pure aluminum, Mg-LaCe alloy, Mg-Y alloy, Mg-Gd alloy, and Mg-Sr alloy at 150°C~200°C for more than 60 minutes; then put pure magnesium and pure aluminum into the melting furnace, with protective gas SF 6 and N 2 Melt in a melting furnace. After all of them are melted, the melt temperature is raised to 720°C, and then the preheated Mg-LaCe alloy, Mg-Y alloy, Mg-Gd alloy and Mg-Sr alloy are added to the melt, fully After melting, stir for 3-5 minutes until the mixture is uniform, remove the scum on the surface, let it stand and cool down to below 660°C, and perform die-casting to obtain the high-strength and high-toughness die-casting magnesium alloy composition such as image 3 shown.

[0053] The mechanical properties of the resulting magnesium alloy at room temperature are as follows:

[0054] Tensile strength UTS=260MPa

[0055] Yield strength YS= 170MPa

[0056] Elongation δ= 4.3%

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com