Hydraulic system for cone crusher

A cone crusher and hydraulic system technology, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as unreasonable hydraulic circuit design, long spare parts storage period, and high operating costs, and achieve Improve maintenance efficiency, facilitate maintenance, and reduce equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

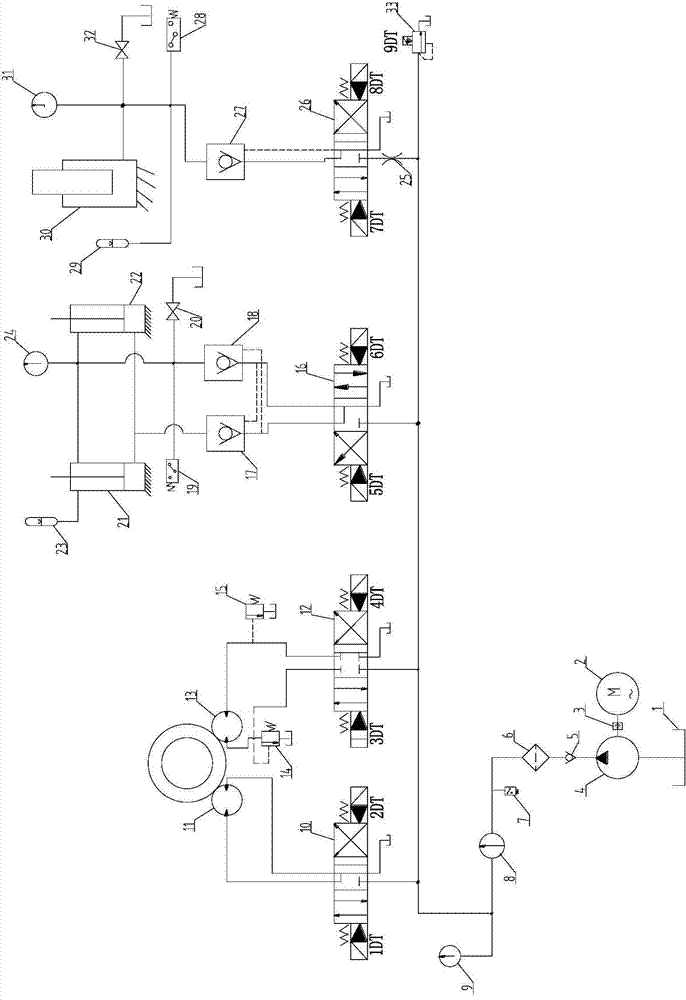

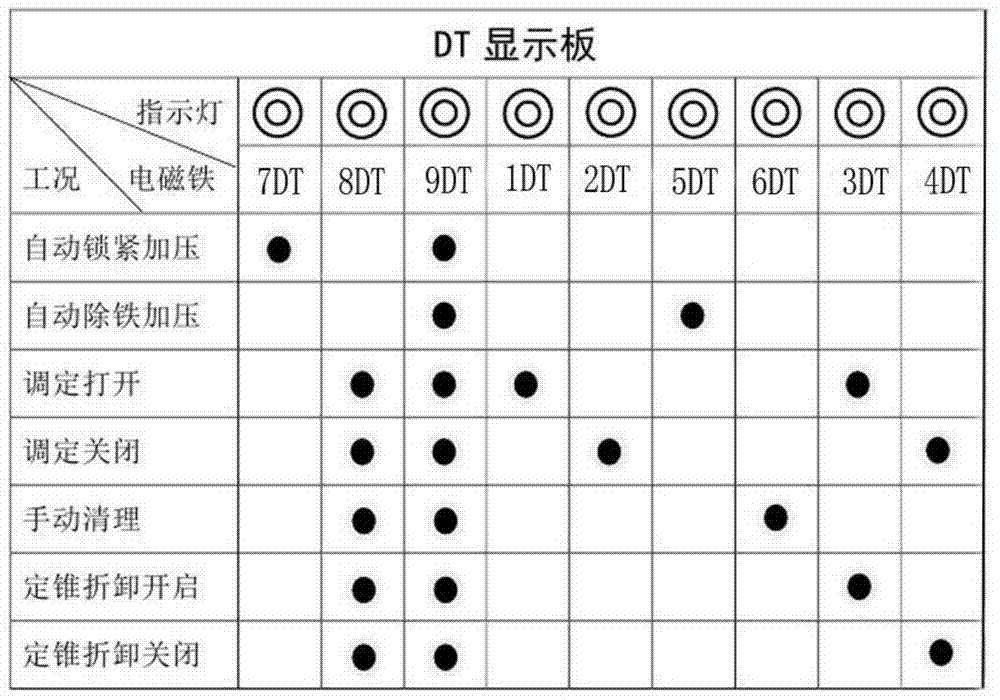

[0020] See figure 1 , is a schematic diagram of the hydraulic system of the present invention, a hydraulic system of a cone crusher of the present invention, including an oil supply system, a locking circuit, an adjustment motor circuit, an iron release and cleaning circuit, and the oil supply system consists of a fuel tank 1, an electric 2 and oil pump 4, the main oil circuit drawn from the oil tank 1 is connected to the locking circuit, the adjustment motor circuit, the iron release and cleaning circuit through the oil pump 4, and the electromagnetic overflow valve 33 is installed at the end, and the main oil circuit behind the oil pump 4 is set in sequence There are one-way valve 5, filter 6, pressure relay-7, flow meter 8 and pressure gauge-9;

[0021] The locking circuit is composed of a plunger cylinder 30 and a three-position four-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com