A liquid fuel electrostatic atomization nozzle with gas-liquid coaxial injection

A technology of liquid fuel and electrostatic atomization, which is applied in the field of electrostatic atomization nozzles and gas-liquid sprays. It can solve the problems of non-conductive liquid fuel atomization devices that have not been reported, the complex structure of dual-fuel nozzles, and the formation of unfavorable ion clusters. , to improve the spray flow field and jet atomization effect, increase the overall surface area, and reduce the droplet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

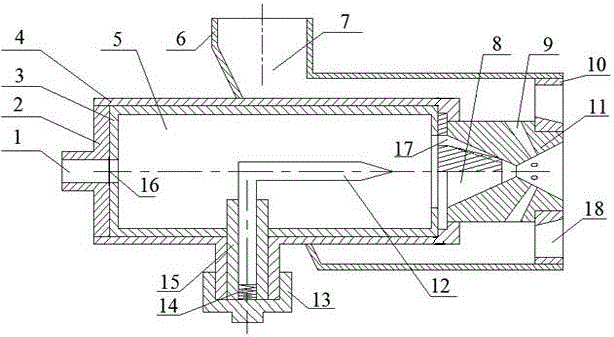

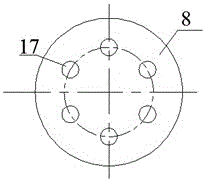

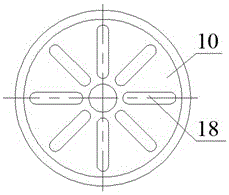

[0022] see figure 1 , the present invention is provided with a cylindrical fuel corona charging chamber 5, the inner wall of the fuel corona charging chamber 5 is an insulating ceramic lining 3, and the outer wall of the insulating ceramic lining 3 is fixedly attached to the cylindrical metal shell 4 On the inner side wall, the metal shell 4 is used not only as the shell of the fuel corona charging chamber 5 but also as the ground electrode. The left end of the fuel corona charging chamber 5 is tightened by the lock nut 2 to fix the insulating ceramic lining 3 in the metal shell 4, which ensures the firmness of the nozzle as a whole. The right end outside the metal shell 4 is covered with an air intake pipeline 6 to form a sleeve structure, and the contact between the metal shell 4 and the air intake pipeline 6 is sealed. The air intake pipeline 6 is sleeved outside the right end of the metal shell 4, and the air intake pipeline 6 is unilaterally air-intaked from the air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com