Double-cylinder type high-precision liquid velocity-flow meter and velocity-flow value output method

A high-precision, dual-tube technology, applied in the field of experimental measurement, can solve the problem of only about 20 cm water column, and achieve the effect of eliminating surface tension and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

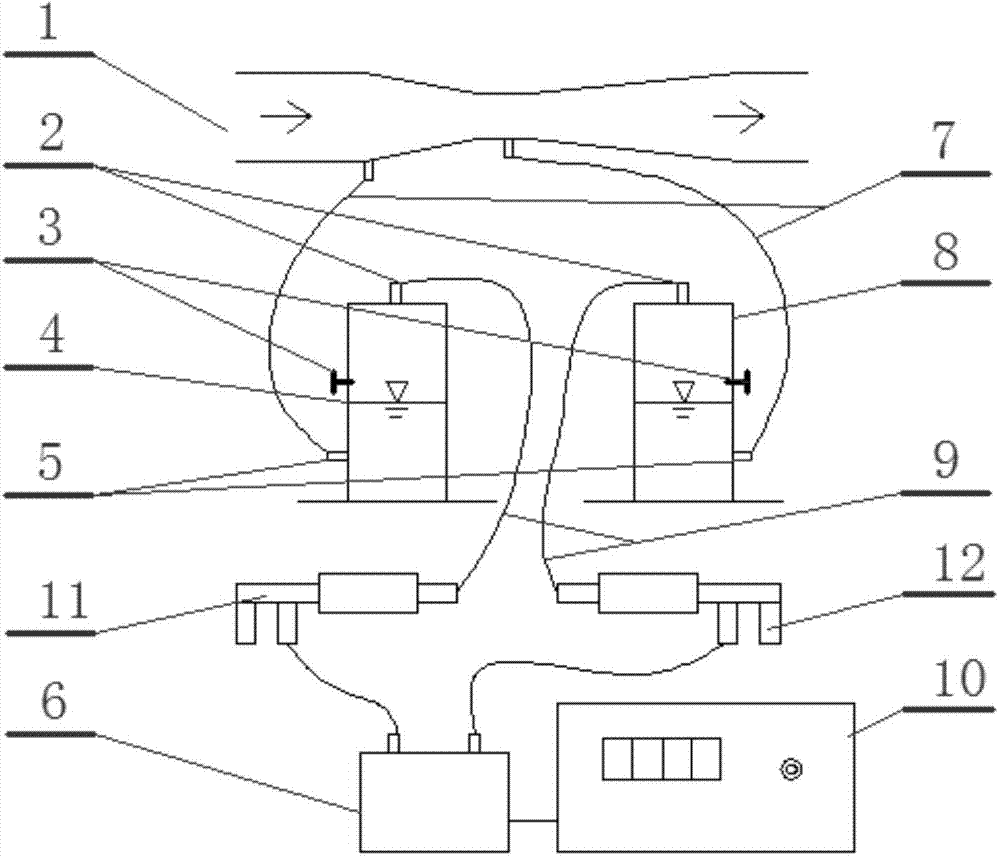

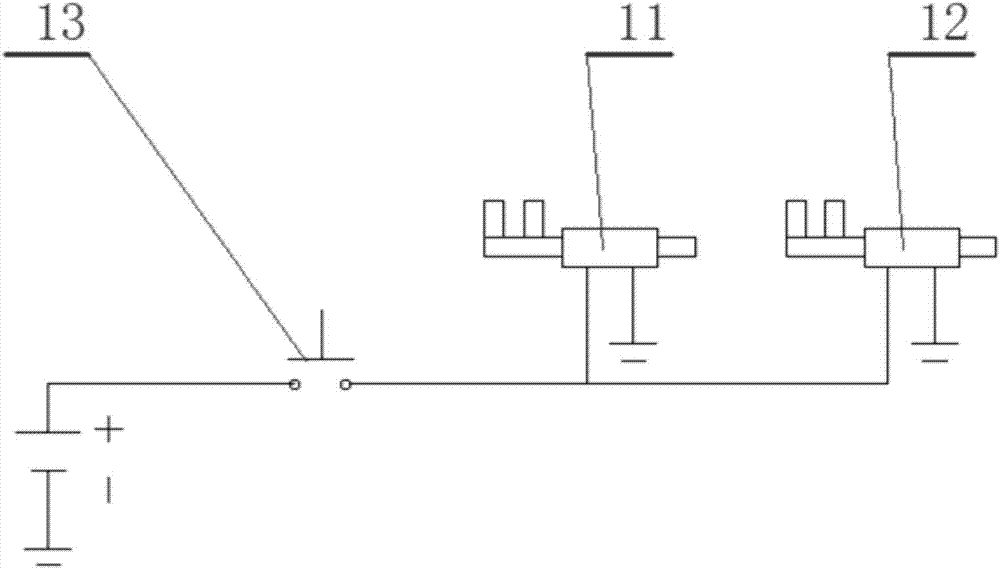

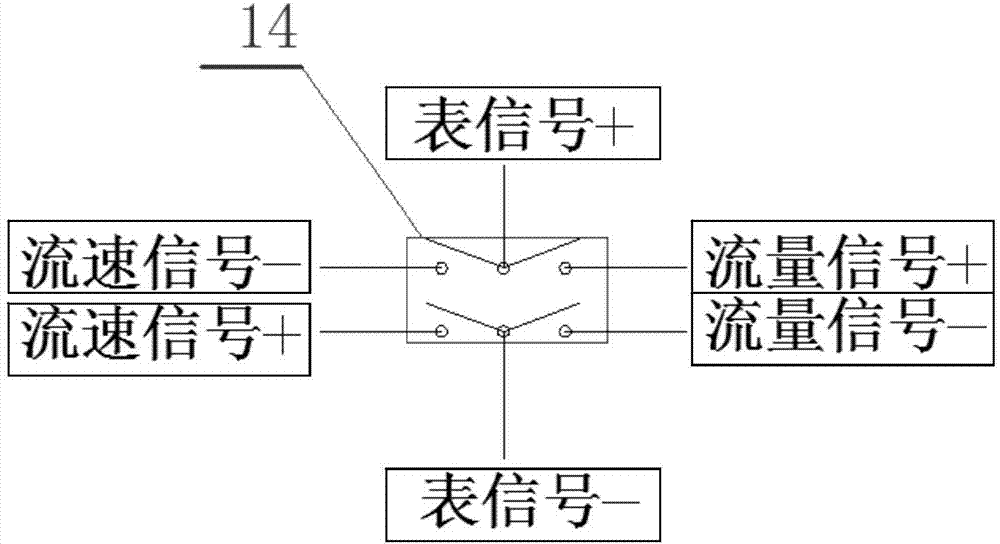

[0047] Such as figure 1 As shown, a dual-barrel type high-precision liquid flow rate flowmeter includes: a differential pressure flow rate signal generator 1 for generating a differential pressure signal; a differential pressure high-end liquid The gas conversion cylinder 4 and the pressure difference low-end liquid-gas conversion cylinder 8, the pressure difference high-end liquid-gas conversion cylinder 4 and the pressure difference low-end liquid-gas conversion cylinder 8 are respectively provided with an air release nozzle 3; The cylinder 4 is connected to the liquid-gas conversion cylinder 8 at the low end of the pressure difference, and is used for detecting the differential pressure sensor 6 of the pressure difference between the compressed air in the high-end liquid-gas conversion cylinder 4 and the compressed air in the liquid-gas conversion cylinder 8 at the low end of the pressure difference; It is connected with the differential pressure sensor 6 and is used for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com