A hydrogen sensor for on-line monitoring of hydrogen concentration in an oil-immersed transformer and its application method

An oil-immersed transformer and sensor technology, which is applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as palladium film shedding, slow response rate, and unstable hydrogen-sensitive materials, so as to improve measurement accuracy and reliability And the effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below through specific examples.

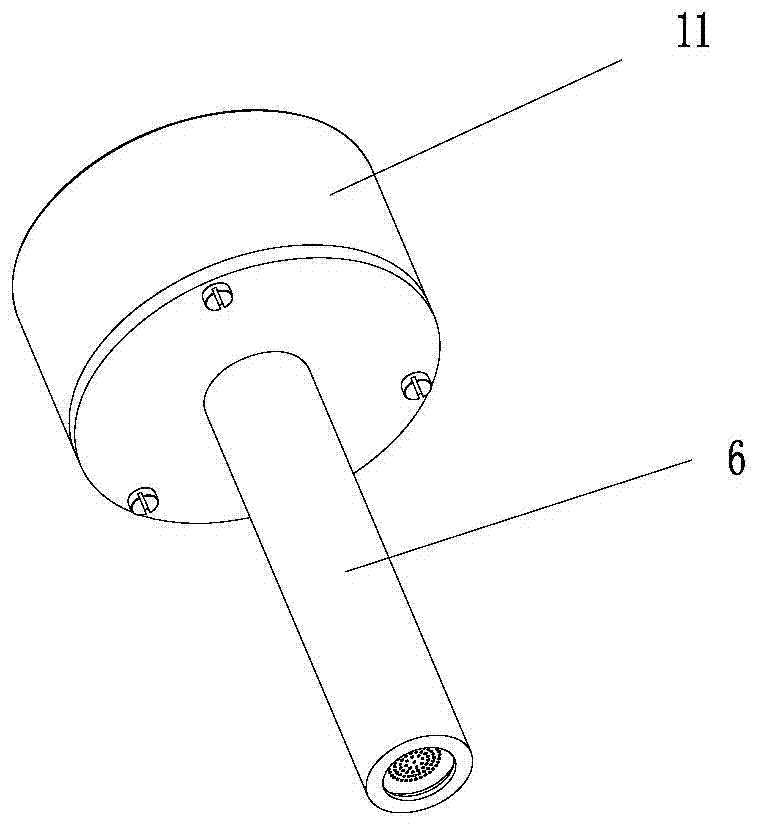

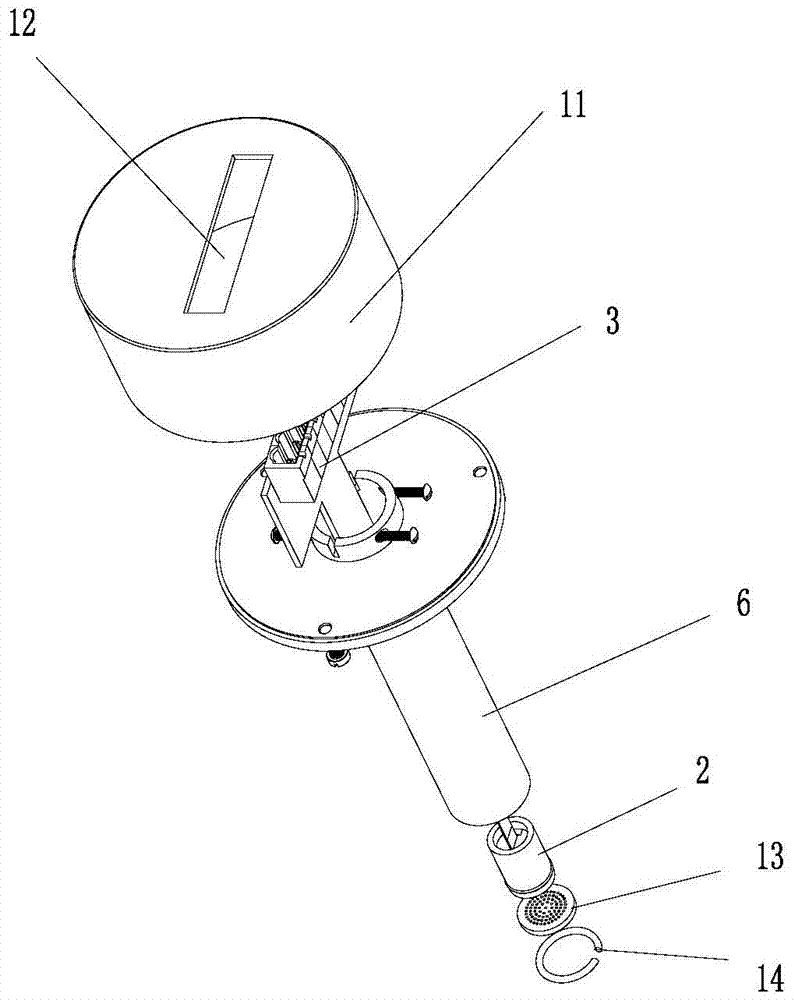

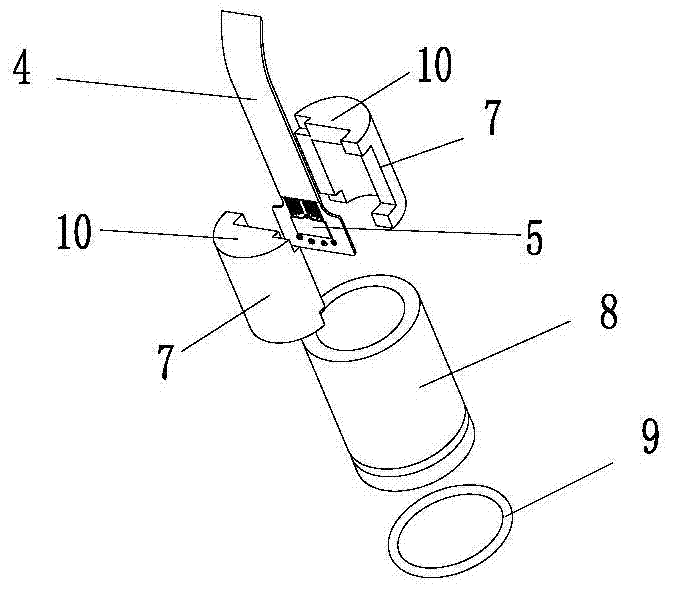

[0042] Such as Figure 1~3 As shown, a hydrogen sensor 1 for on-line monitoring of hydrogen concentration in oil-immersed transformers, the hydrogen sensor 1 includes a hydrogen sensitive probe 2 and a circuit module 3 for signal conversion and outputting electrical signals, the hydrogen sensitive probe 2 includes A cable flat wire 4 electrically connected to the circuit module 3 at one end, a hydrogen sensitive chip 5 electrically connected to the other end of the cable flat wire 4 and in direct contact with the transformer oil, the hydrogen sensitive chip 5 includes a substrate, and an electrical insulating layer arranged on the substrate And the hydrogen sensitive element arranged on the electrical insulation layer, the surface of the hydrogen sensitive element is provided with a hydrogen-specific coating for inhibiting the diffusion of gas molecules other than hydrogen.

[0043] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com