An ultrasonic automatic inspection device for large cylinder and head forgings

A large-scale, automatic inspection technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of human influence on inspection quality and heavy manual inspection, avoid difficulty in probe movement, reduce electromagnetic interference, and achieve obvious results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

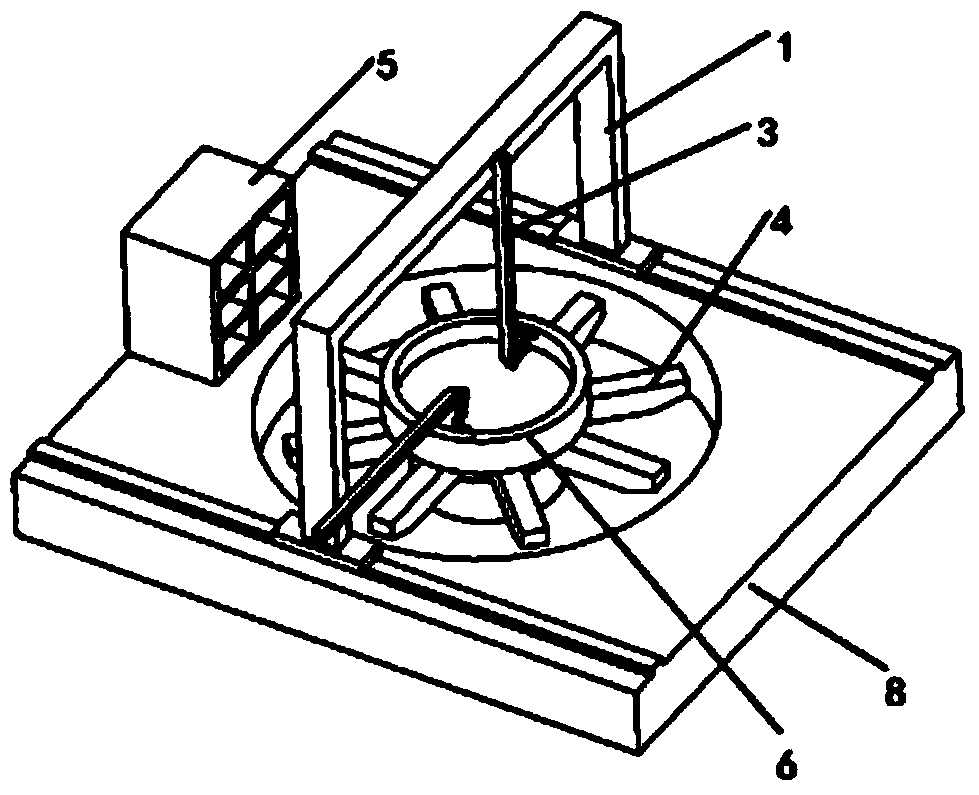

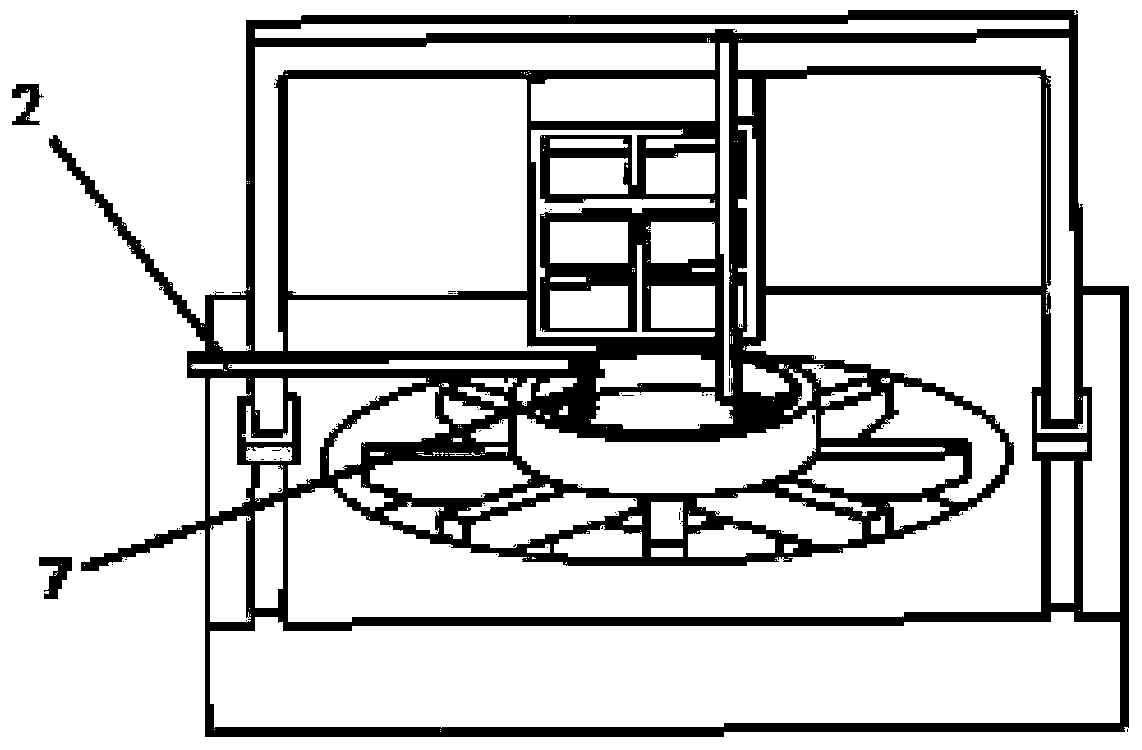

[0028] Such as figure 1 As shown, the ultrasonic automatic inspection device for large cylinder and head forgings in the present invention includes a door guide rail 1, a horizontal telescopic rod 2, a vertical telescopic rod 3, a rotary table 4, a test block storage rack 5, a gong-shaped forging 6, a swing Type linear module 7, installation base 8; door guide rail 1 is installed on the installation base 8, there is a sunken circular groove in the middle of the installation base 8, the rotary table 4 is placed in it, and the horizontal telescopic rod 2 is installed on the door guide rail 1 in the vertical direction and can slide along it, the vertical telescopic rod 3 is installed on the portal rail 1 in the horizontal direction and can slide along it, the swinging linear module 7 is installed on the heads of the horizontal telescopic rod 2 and the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com