Fault diagnosis method and system for heading machine hydraulic system

A hydraulic system and fault diagnosis technology, which is applied in neural learning methods, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inconvenient human-computer interaction, low accuracy of fault diagnosis, and imperfect knowledge base, etc., to achieve Easy to expand, good human-computer interaction interface, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] There are many physical parameters caused by a certain fault. To diagnose the fault of the hydraulic system, the parameters reflecting the state of the hydraulic system must be extracted first. When the hydraulic system fails, these parameters will change directly or indirectly. Therefore, by analyzing the By analyzing the changes of these parameters, we can diagnose the failure of the system. If the characteristic parameters are not selected properly, it will increase the difficulty of diagnosis. Too many choices may generate redundant information and increase the cost of collection. Too few will reduce the accuracy of diagnosis and may even cause misjudgment. The diagnosis of faults plays a vital role.

[0028] A fault diagnosis method for a hydraulic system of a roadheader includes the following steps:

[0029] Step (1), firstly extract the parameters that reflect the state of the hydraulic system. The extracted parameters of the state of the hydraulic system includ...

Embodiment 2

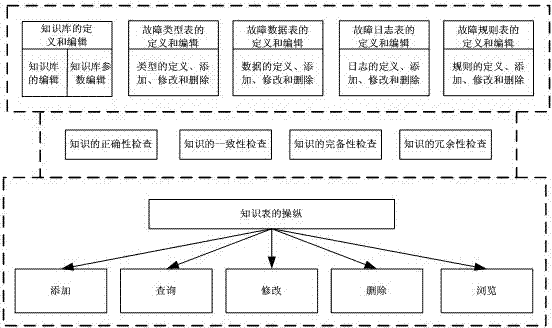

[0035] Such as figure 1 , is the basic structure of the knowledge base management system of the roadheader hydraulic fault diagnosis system of the present invention. The overall structure of the designed fault diagnosis KBMS is divided into three layers. Among them, the surface layer functions of the knowledge base are directly oriented to the database to implement operations such as adding, querying, modifying, and deleting knowledge in the database. The inspection management of the knowledge base layer acts as a link between the functions of the two layers; the knowledge base management layer is application-oriented and directly calls the functions of the knowledge base layer for various operations of the knowledge base management. In practical applications, the knowledge base is divided into three layers of call forms, that is, the functions of each layer are set to complete different functions

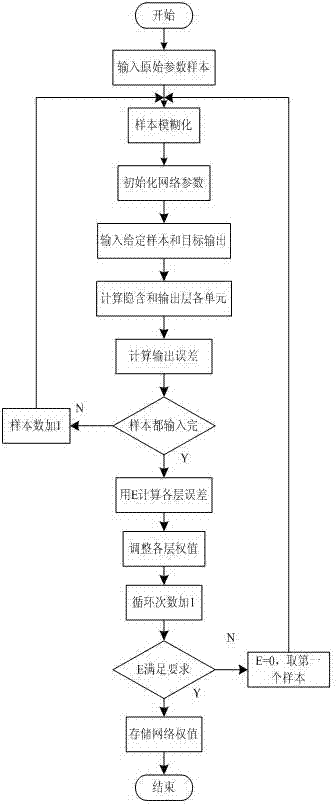

[0036] Such as figure 2 , is the fuzzy neural network fault diagnosis mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com