Laser collaboration temperature control and seal mounting base

A laser and mounting base technology, applied in the laser field, can solve the problems of the overall structure of the laser cannot be used together, the current drive and temperature drive cable interfaces are separated, the laser beam collimation adjustment is cumbersome and inflexible, etc., so as to reduce the overall structure volume and improve the Stability and reliability, effect of simplified longitudinal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

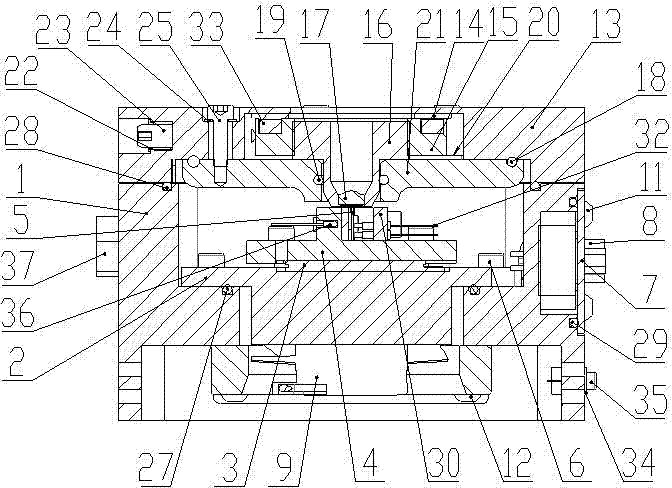

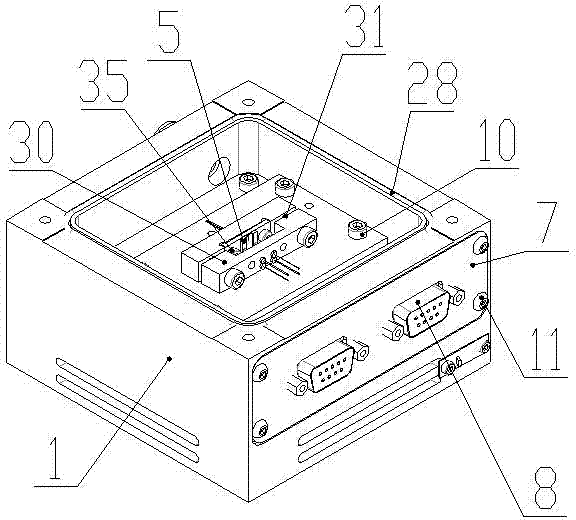

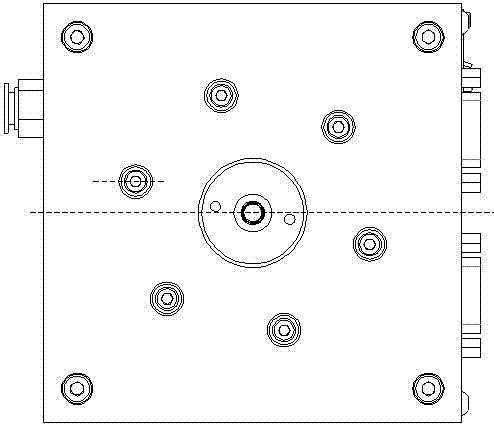

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] The parts of device of the present invention are as follows:

[0039] The frame body 1 is in the shape of a cuboid and is used to surround other components to form a closed internal environment and play the role of protection, support and installation;

[0040] Sealed DB9 fixing plate 7, located on the side of the frame, used to fix and seal DB9 electronic connector 8;

[0041] Sealed DB9 electronic connector 8, two, respectively used to connect the standard connectors of laser current drive and temperature drive;

[0042] The vibration isolation fan 9 is arranged on the bottom surface of the mounting base, and is used to accelerate the internal air flow of the mounting base to accelerate heat dissipation; the vibration isolation fan is provided with a switch 34, which is located at the bottom right of the sealed DB9 electronic connector, and is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com