Full-rotor hub motor

A technology of rotor hub and hub, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of limiting the performance of electric vehicles, large working current, heavy weight, etc., to facilitate large-scale industrial production, high efficiency, wide area, carbon Less brush wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment do further description:

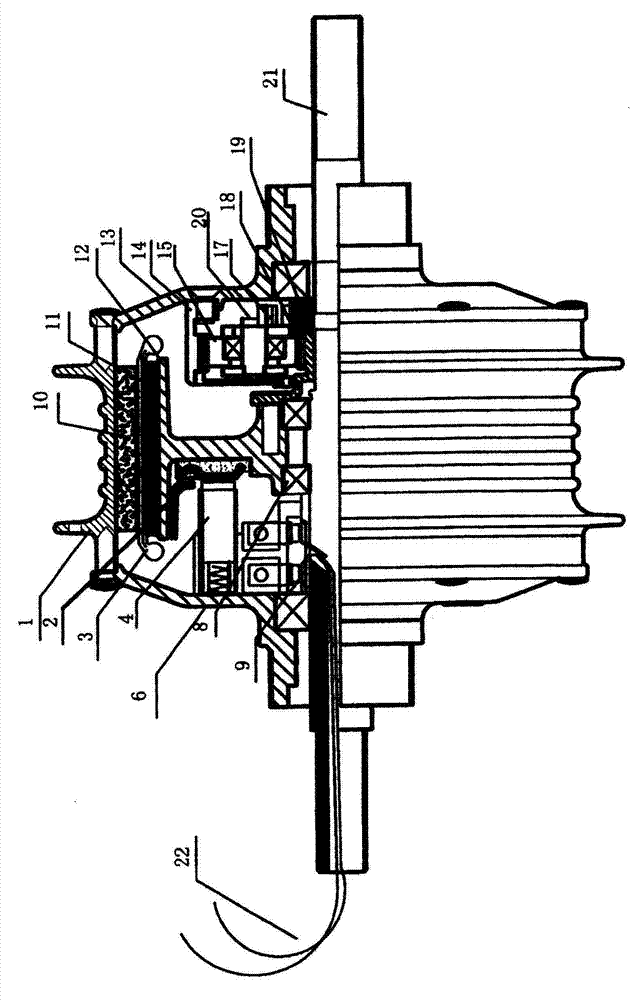

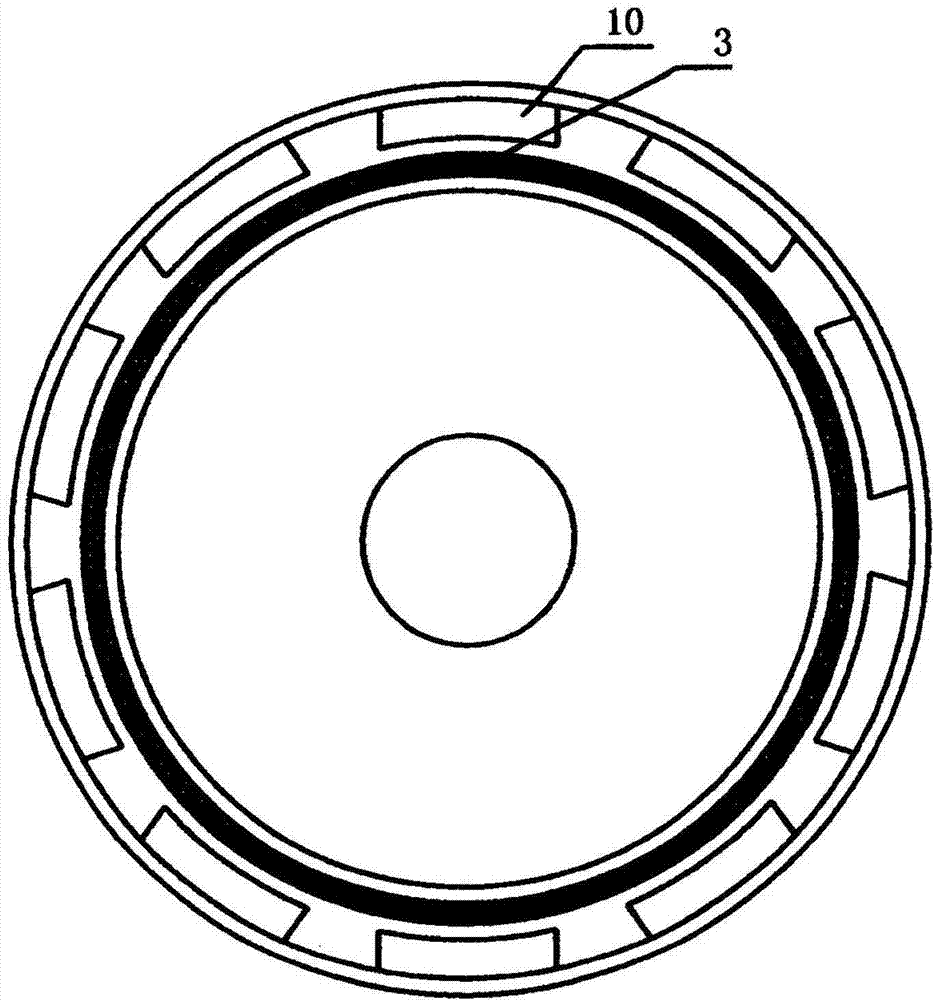

[0013] See attached figure 1 And attached figure 2 As shown, the full-rotor hub motor includes a motor shaft 21, a hub shell, an inner rotor frame 12 and a planetary reduction mechanism. The hub shell includes a motor iron shell 1, a permanent magnet 10 fixed to the inner ring of the motor iron shell 1 and The left end cover 6 and the right end cover 13 fixedly connected with the motor iron shell 1, the left end cover 6 and the right end cover 13 are fixed on the motor shaft 21 through bearings, so that the hub shell constitutes the outer rotor of the motor, and the inner rotor frame 12 A ring-shaped yoke 11 is fixed, and an armature 3 is fixed on the outer surface of the yoke 11. The inner rotor frame 12 is connected with the motor shaft 21 through the inner rotor bearing 8 to form an inner rotor, and one side of the inner rotor frame 12 is fixedly connected. With the commutator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com