Drive device and device manufacturing method

A driving device and driving force technology, applied in the electromechanical field, can solve problems such as high power consumption and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

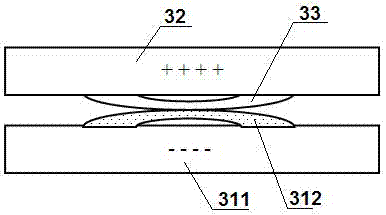

[0039]A method for manufacturing a variable capacitor, the stator and the mover respectively include a first electrode and a second electrode with opposite or same polarity charges, the deformation connector is a spring sheet, and the first original force includes the first electrode and the second electrode The electrostatic attraction or repulsion between the stator and the mover also includes piezoelectric ceramics or memory metals. The external driving force includes the deformation force generated by the piezoelectric ceramics or memory metals after electrification. The springs are made of high dielectric The electric constant material has an insulating coating on its surface, or can be integrated with piezoelectric ceramics or memory metals.

[0040] The first original force is electrostatic force, which only needs to be supplemented in the case of leakage, and basically does not consume external energy. A driving device (variable capacitor) made according to the above m...

Embodiment 12

[0043] A method for manufacturing a variable focal length lens, the stator and the mover respectively include a first electrode and a second electrode with opposite or same polarity charges, the deformation connector is a spring sheet, and the first original force includes the first electrode and the second electrode. The electrostatic attraction or repulsion between the electrodes, the stator also includes piezoelectric ceramics or memory metal, the external driving force includes the deformation force generated after the piezoelectric ceramic or memory metal is energized, the mover has a hollow structure, and the interior is used to install the focus or zoom lens group.

[0044] A driving device (variable focal length lens) made according to the above method can be referred to Figure 4 , the basic structure and image 3 Similarly, the support piece 413 and the positive metal sheet 411 act as a stator, the other positive metal sheet 42 acts as a mover, and the piezoelectric...

Embodiment 13

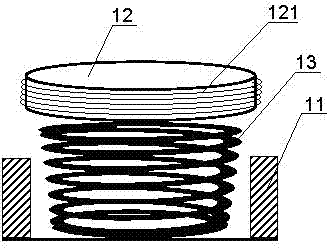

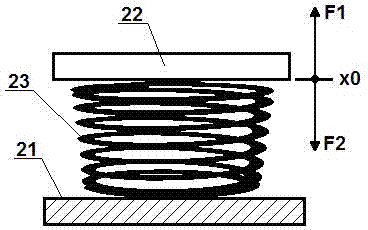

[0047] A method for manufacturing a natural energy generator, the mover includes a first magnet, the first magnet is a permanent magnet, the deformable connector is a spring or a coil spring, the material of the so-called coil spring includes a conductive material, and is used as an excitation coil. The sub is used as a generator mover or used to drive a generator mover. The external driving force includes an external force acting on the mover. The external force comes from a natural energy source. The first magnet is set on the slope of the curved surface. The first original force includes the first magnet The component of gravity in the direction opposite to the coil spring force. Since the variation coefficient of gravity with position is very small in the free state, a curved surface slope is used to increase the variation coefficient of the component of gravity in the direction opposite to the spring force of the coil spring with position.

[0048] A driving device (natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com