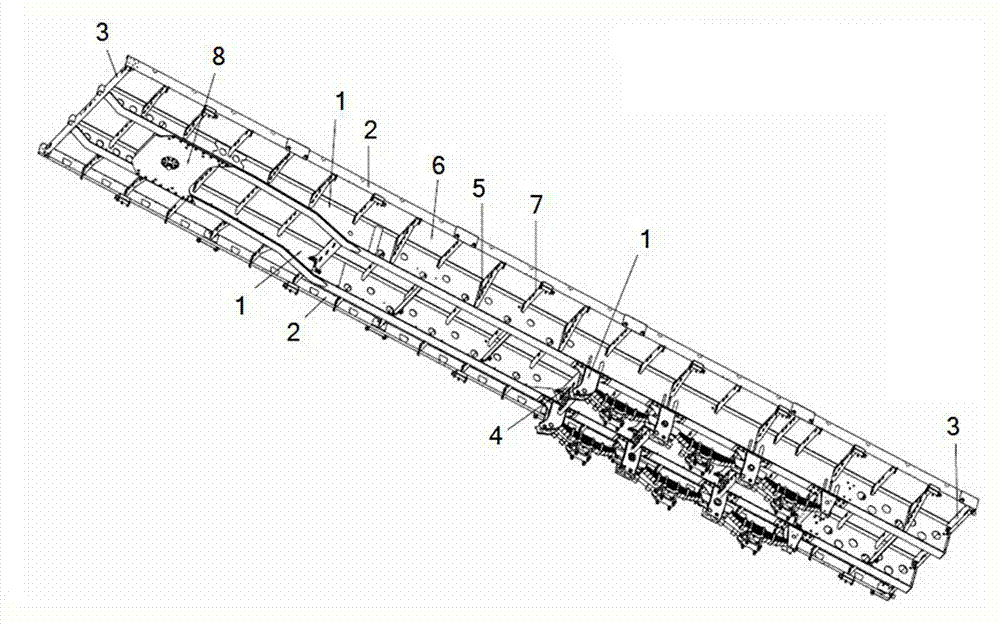

Assembled semi-trailer frame

A semi-trailer and assembled technology, which is applied to vehicle components, transportation and packaging, and substructure, can solve the problems of increasing semi-trailer transportation costs, inability to disassemble the packaging, and welding defects, and achieve convenient processing and overall assembly. Parts are produced in batches to prevent the effect of bouncing up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

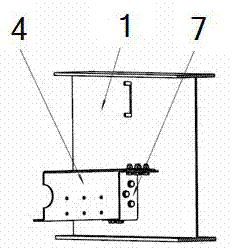

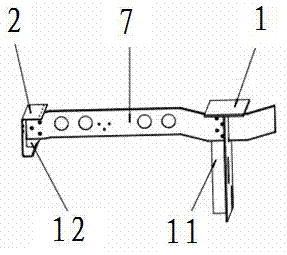

[0020] The labels of the drawings are as follows: 1 longitudinal beam, 2 side beams, 3 front and rear beams, 4 middle beam, 5 lower support, 6 base plate, 7 through beam, 8 traction pin plate and bracket, 9 suspension bracket, 10 zigzag bracket , 11 longitudinal beam connecting plate, 12 side beam connecting plate, 13 traction pin plate bracket, 14 traction pin plate, 15 suspension bracket connecting plate, 16 connecting beam, 17 reinforcing plate, 18 fence hinge, 19 fence frame, 20 supplement strong plate, 21 stringer web, 22 stringer lower wing.

[0021] An assembled semi-trailer frame according to the present invention, the frame is installed on the bottom plate, the difference from the prior art is that the frame is composed of longitudinal beams, middle beams connected with the longitudinal beams and Composed of through beams, two side beams are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com