A polysiloxane softener with color-fixing properties

A technology of polysiloxane and softener, which is applied in the field of polysiloxane softener and its preparation, can solve the problems of poor softening performance and no color fixing performance of polysiloxane softener, and achieve soaping fastness Good, stable storage, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

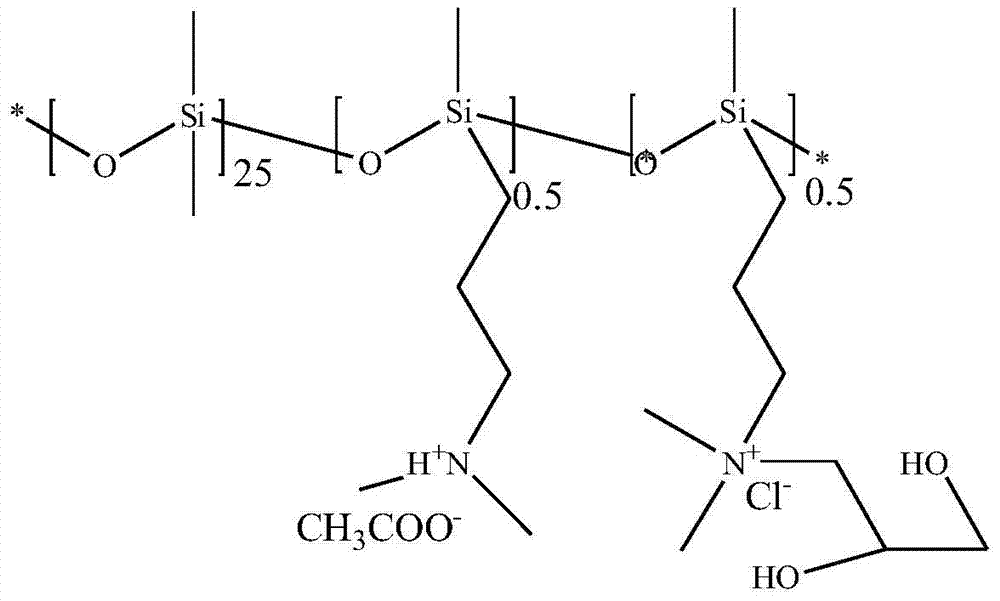

[0035] In a 2000ml four-necked flask, 740g of octamethylcyclotetrasiloxane (D 4 ), 76.4g (0.4mol) dimethylaminopropylmethyldimethoxysilane and basic catalyst were mixed and heated and stirred, 7.2g of water was added dropwise, heated to 110°C for 3h, cooled to 78°C, added 222g To isopropanol, add 22g (0.2mol) 3-chloro-1,2-propanediol dropwise, react at 78-80°C for 2 hours, cool down to 50°C, add 12g (0.2mol) acetic acid, and put the mixture at 80°C The isopropanol was distilled off to obtain a turbid, highly viscous liquid sample 1, which was described by the following general statistical formula:

[0036]

Embodiment 2

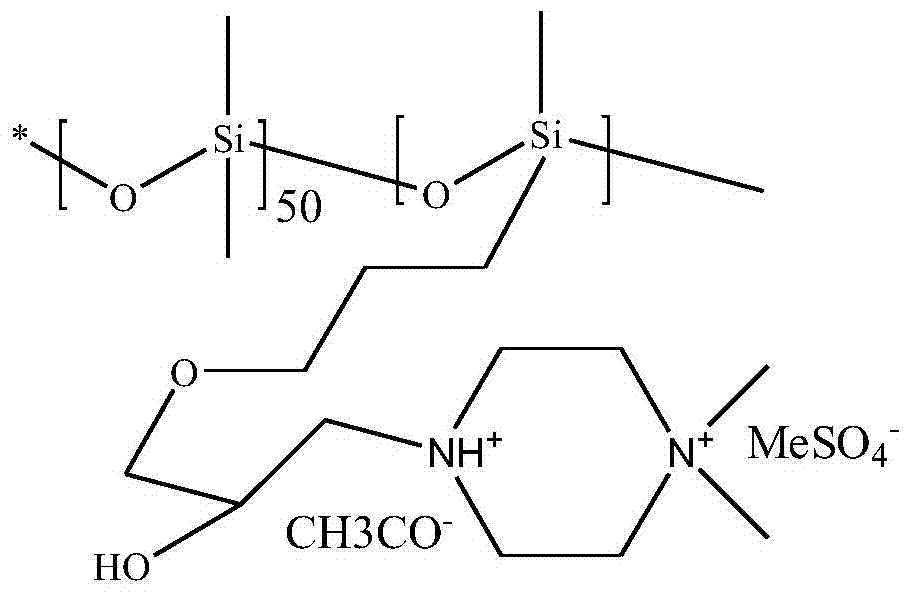

[0038] In a 2000ml four-necked flask, mix 44g (0.2mol) 3-[(2,3)-glycidoxy]propylmethyldimethoxysilane and 20g (0.2mol) methylpiperazine at room temperature , avoid light and isolate the air reaction for 24h, add 740g octamethylcyclotetrasiloxane (D 4 ) and the basic catalyst were mixed and heated and stirred, 3.6g of water was added dropwise, heated to 110°C for 3h, cooled to 78°C, 222g of isopropanol was added, 25.2g (0.2mol) of dimethyl sulfate was added dropwise, at 78 ~80 DEG C slight boil reaction 2h, cool down to 50 DEG C, add 12g (0.2mol) acetic acid, this mixture is distilled off isopropanol at 80 DEG C, obtain cloudy high-viscosity sample 2, it is described by the following statistical general formula:

[0039]

Embodiment 3

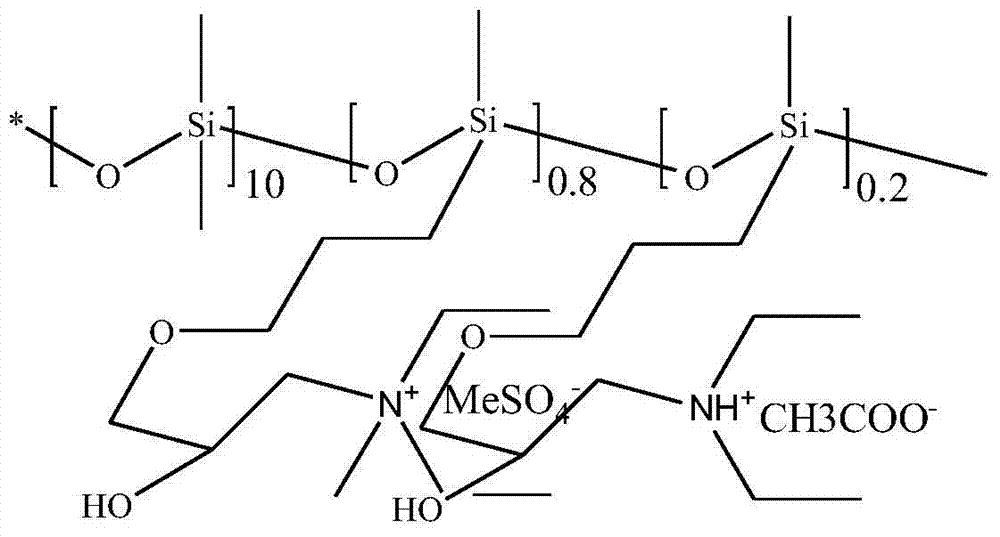

[0041] In a 2000ml four-necked flask, mix 220g (1mol) of 3-[(2,3)-glycidoxy]propylmethyldimethoxysilane and 74g (1mol) of diethylamine at room temperature and keep away from light Isolate the air and react for 24 hours, add 740g linear body (WS-62M) and basic catalyst to mix and heat and stir, add 18g of water dropwise, heat to 110°C for 3h, cool down to 78°C, add 222g of isopropanol, add dropwise 100.8 g (0.8mol) of dimethyl sulfate, react at 78-80°C for 2 hours, cool down to 50°C, add 12g (0.2mol) of acetic acid, distill the mixture at 80°C to distill isopropanol to obtain a cloudy high-viscosity sample 3, which is described by the following general statistical formula:

[0042]

[0043] Composition Examples:

[0044] The samples 1-3 obtained in the above examples were emulsified into corresponding compositions 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com