A method for oxidative desulfurization of catalytic fuel oil using multi-acid intercalation trimethylol hydrotalcite and ionic liquid extraction

A technology of trimethylol hydrotalcite and trimethylol water, applied in chemical instruments and methods, petroleum industry, physical/chemical process catalysts, etc., can solve the problem of increasing equipment investment and operating costs, and reducing the octane number of oil products. , and no large-scale promotion, etc., to achieve the effects of easy recycling, short response time, and accurate detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

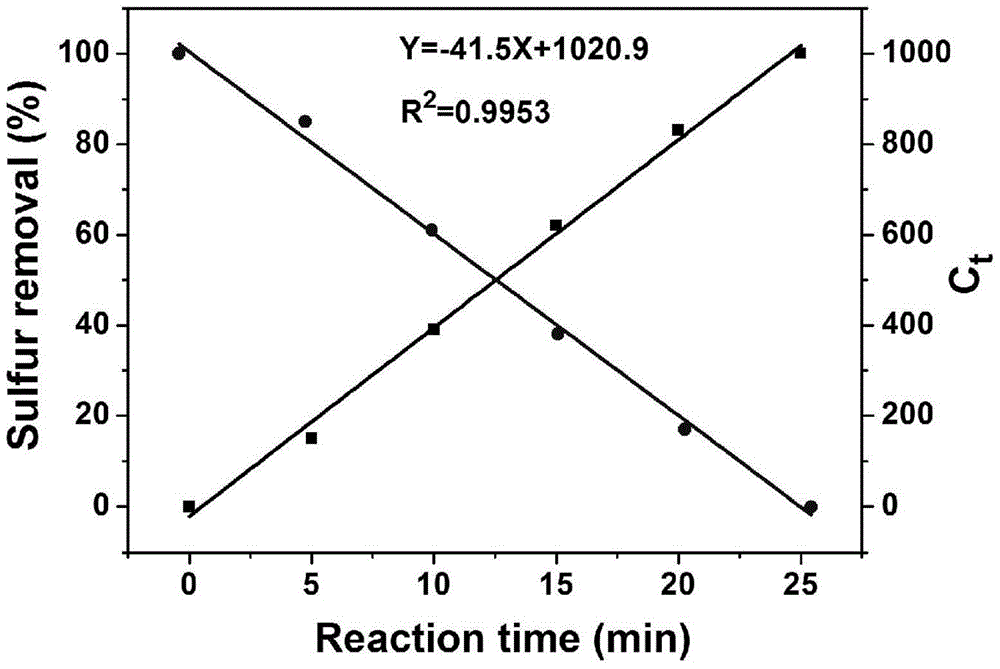

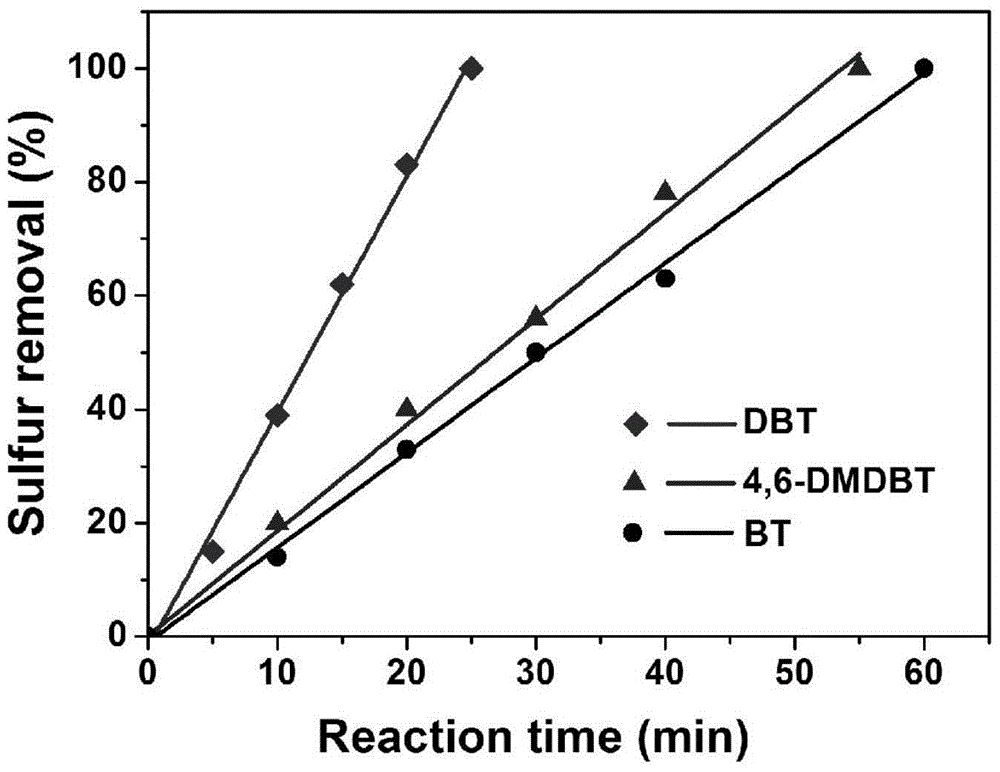

[0027] 1. Preparation of simulated fuel oil: 1.4662 g (7.793 mmol, 98%) of DBT was dissolved in n-octane to prepare 250 mL of simulated fuel oil with a sulfur content of 1000 ppm.

[0028] 2. Tris-NH 2 -PW 12 -The preparation method of LDH: 1), prepare the mixed solution of magnesium chloride, aluminum chloride and tris (hydroxymethyl) aminomethane, hydrothermal reaction 15 hours under 50 ℃; Gained precipitation 2g is dispersed in 100mL concentration and is the Na 2 CO 3 After ion exchange in the solution for 2 hours, centrifuge, wash and dry to obtain Tris-NH 2 -CO 3 -LDH; the mol ratio of magnesium chloride and aluminum chloride is 3:1, the concentration of magnesium chloride is 10mM, and the concentration of tris(hydroxymethyl)aminomethane is 0.1M;

[0029] 2). Prepare Na with a concentration of 0.1M 3 [PW 12 o 40 ]·15H 2 O solution, then Tris-NH 2 -CO 3 -LDH 20mg added to 25mLNa 3 [PW 12 o 40 ]·15H 2 In O solution, Na 3 [PW 12 o 40 ]·15H 2 O and Tris-NH ...

Embodiment 2

[0034] 1. The preparation of simulated fuel oil: with embodiment 1.

[0035] 2. Tris-CH 3 -SiW 12 -The preparation method of LDH: 1), prepare the mixed solution of magnesium chloride, aluminum chloride and trimethylolethane, hydrothermal reaction 5 hours under 150 ℃; 2 CO 3 After ion exchange in the solution for 1 hour, centrifuge, wash and dry to obtain Tris-CH 3 -CO 3 -LDH; the molar ratio of magnesium chloride to aluminum chloride is 2:1, the concentration of magnesium chloride is 50mM, and the concentration of trimethylolethane is 3M;

[0036] 2). Prepare Na with a concentration of 10M 3 [SiW 12 o 40 ]·15H 2 O solution, then Tris-CH 3 -CO 3 -LDH 50mg added to 25mLNa 3 [SiW 12 o 40 ]·15H 2 In O solution, Na 3 [SiW 12 o 40 ]·15H 2 O and Tris-CH 3 -CO 3 The molar ratio of -LDH is 3, after stirring for 2 hours without nitrogen protection, it is centrifuged and washed, and dried in vacuum to obtain Tris-CH 3 -SiW 12 -LDH.

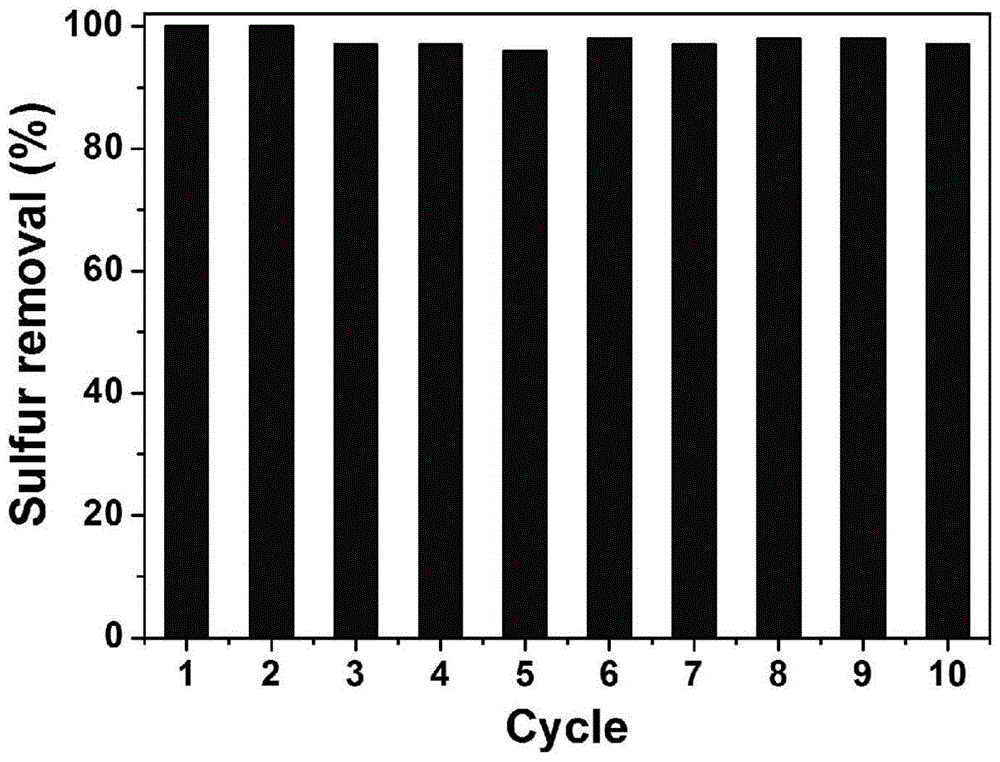

[0037] 3 Catalytic oxidation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com