Special natural softener for textiles and preparation method for special natural softener

A softener and textile technology, which is applied in the field of special natural softener for textiles and its preparation, can solve problems such as unfavorable human health, unfavorable ecological cycle development, etc., to improve decontamination and moisturizing functions, improve skin problems, and prevent fork effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

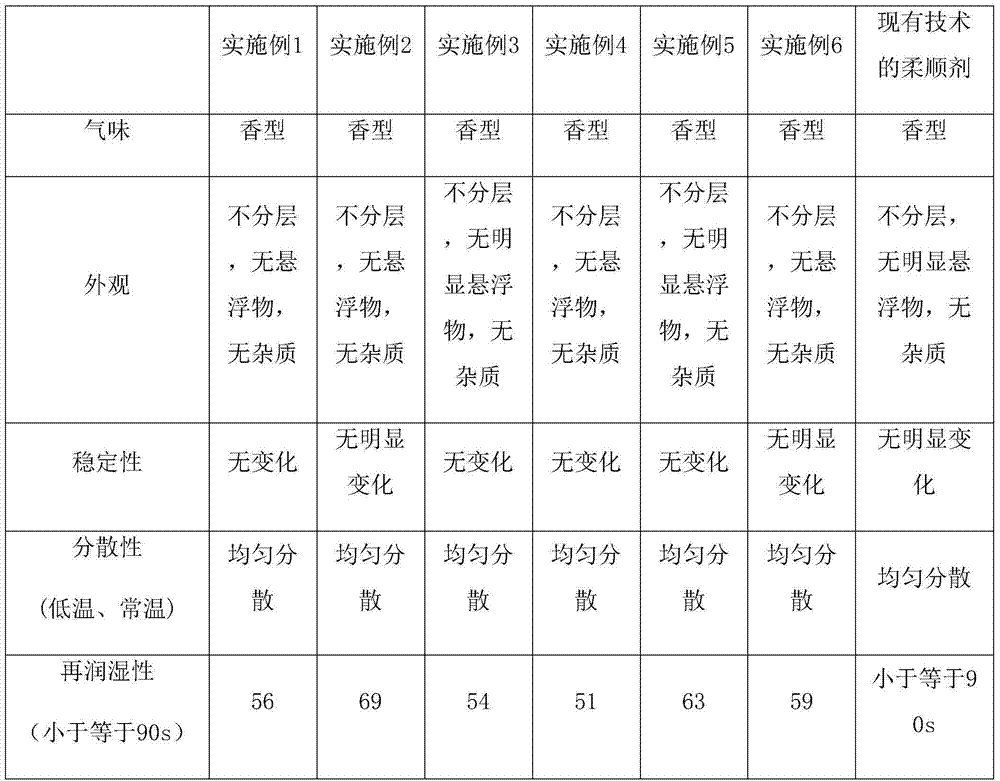

Examples

Embodiment 1

[0029] (1) In parts by weight, add 2 parts of ginseng extract, 4 parts of schisandra seed extract, 3 parts of lavender extract, 15 parts of coconut oil derivatives and 20 parts of lemon extract to 100 parts of deionized In water, heat it to 80° C., keep it warm, stir evenly, and filter to obtain a natural extract clear liquid with a mass fraction of 23%.

[0030] (2) Dissolve 2 parts of Gemini quaternary ammonium salt containing ester groups in 50 parts of deionized water, heat to 40°C, stir until uniform, then mix with natural extract clear liquid at a volume ratio of 1:1, and finally add 10 parts The acrylamide and deionized water are mixed evenly, the pH value is adjusted to 6.5, the water content is 50%, and the homogenization is lowered to room temperature to obtain a special natural softener for textiles.

[0031] The method of use is: add 7 parts of natural softener to 100 parts of deionized water, mix well, soak the textile in it, rinse for 5 minutes, take it out, remo...

Embodiment 2

[0033] (1) In parts by weight, add 5 parts of ginseng extract, 7 parts of schisandra seed extract, 8 parts of lavender extract, 18 parts of coconut oil derivatives and 25 parts of lemon extract to 100 parts of deionized In water, heat it to 80° C., keep it warm, stir evenly, and filter to obtain a natural extract clear liquid with a mass fraction of 28%.

[0034] (2) Dissolve 5 parts of Gemini quaternary ammonium salt containing ester groups in 50 parts of deionized water, heat to 50°C, stir until uniform, then mix with natural extract clear liquid at a volume ratio of 1:1, and finally add 15 parts The ethanol, acrylamide and citric acid are mixed evenly, the pH value is adjusted to 7.5, the water content is 60%, and the homogenization is lowered to room temperature to obtain a special natural softener for textiles.

[0035] The method of use is: add 10 parts of natural softener to 100 parts of deionized water, mix evenly, soak the textile in it, rinse for 10 minutes, take it ...

Embodiment 3

[0037] (1) In parts by weight, add 4 parts of ginseng extract, 5 parts of schisandra seed extract, 6 parts of lavender extract, 16 parts of coconut oil derivatives and 22 parts of lemon extract to 100 parts of deionized In water, heat it to 80° C., keep it warm, stir evenly, and filter to obtain a natural extract clear liquid with a mass fraction of 25%.

[0038] (2) Dissolve 4 parts of Gemini quaternary ammonium salt containing ester groups in 50 parts of deionized water, heat to 45°C, stir until uniform, then mix with natural extract clear liquid at a volume ratio of 1:1, and finally add 12 parts The acrylamide, citric acid and deionized water were mixed uniformly, the pH value was adjusted to 7, the water content was 55%, and the homogenization was lowered to room temperature to obtain a special natural softener for textiles.

[0039] The method of use is: add 8 parts of natural softener to 100 parts of deionized water, mix well, soak the textile in it, rinse for 7 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com