Steam generating method for preparing liquid air

A liquid air and steam generating device technology, applied in refrigeration and liquefaction, liquefaction, lighting and heating equipment, etc., can solve the problems of energy saving and emission reduction, loss, cooling water taking away, etc., and achieve the effect of efficient use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

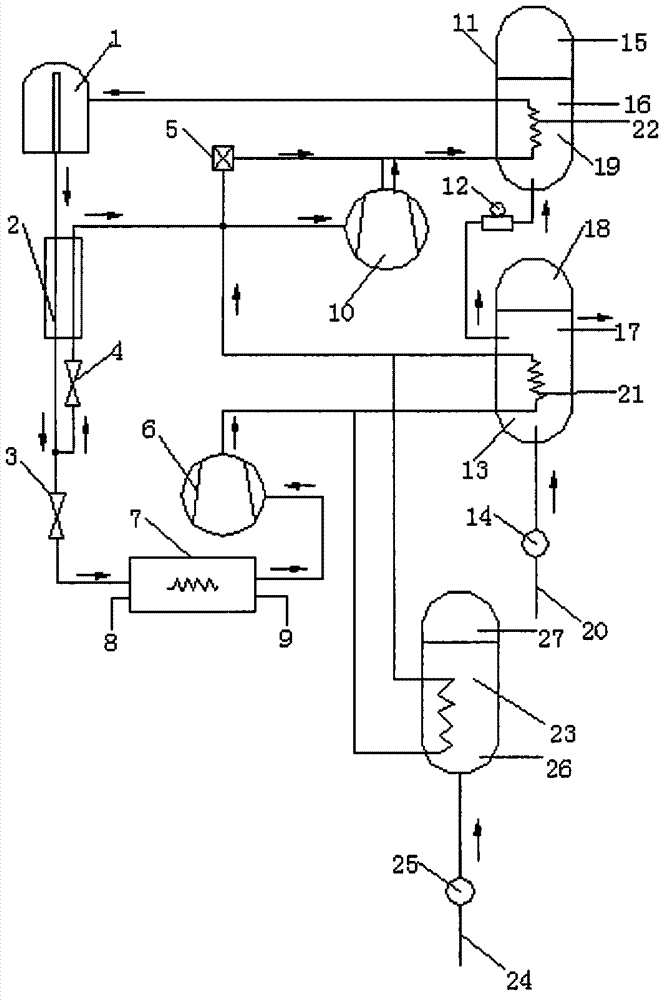

[0012] refer to figure 1 , the specific embodiment adopts the following technical solutions: a steam generating device capable of preparing liquid air, including an air and liquid storage tank 1, a regenerator 2, a low-pressure expansion valve 3, a high-temperature expansion valve 4, a solenoid valve 5, a low-temperature compression Machine 6, evaporator 7, high temperature compressor 10, steam water tank 11 and liquid air tank 23, described hot water tank 18 and steam water tank 11 are provided with condensation heater 21 and condensation heater 22 inside, described evaporator 7 is provided with a heat source liquid inlet 8 and a heat source liquid outlet 9, the evaporator 7 and the low temperature compressor 6, the internal condensation heater 21 of the hot water tank 18, the high temperature compressor, the internal condensation heater 22 of the steam water tank 11, the air And the liquid storage tank 1 and the regenerator 2 are sequentially connected through pipelines to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com