Liquefied nitrogen tank

A liquid nitrogen tank and tank body technology, which is applied in the field of liquid nitrogen tanks, can solve the problems of the overall weight of the lifting cylinder, fast consumption of liquid nitrogen, and increased consumption of liquid nitrogen, and achieve the effects of avoiding direct contact, simple design, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

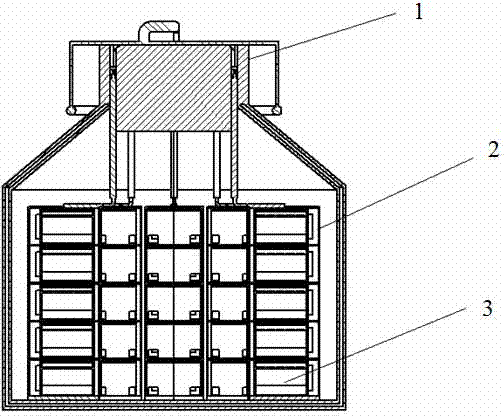

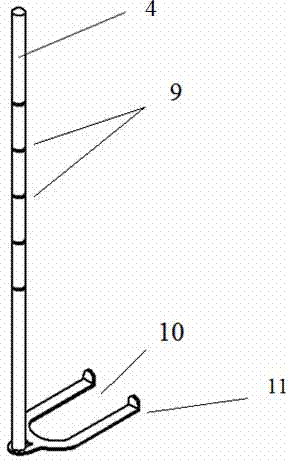

[0023] The liquid nitrogen tank of the present invention includes a tank body, a lifting cylinder 2, a freezing storage box 3, and a lifting fork 4. The lifting cylinder 2 is placed in the hollow cavity provided by the tank body, and the freezing storage box 3 is placed in the lifting cylinder 2. The box cover plate 6 is fixed on the top of the freezer box 3, and the top of the tank body is fixed with a tank cover. The fork head 10 includes a fork handle and a fork head 10 arranged at the bottom of the fork handle, and the fork handle is perpendicular to the lifting fork 4 , the fork handle is provided with a layer number scale 9, and the handle of the lifting tube 2 is provided with a hand-held mark 5, which corresponds to the layer number scale 9, and the fork head 10 provided by the lifting fork 4 is inserted into the bottom of the freezer box 3. The provided slot 8 and the provided fork hook 11 at the end of the fork 10 can hook the freezer box 3 out of the lifting tube 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com