A Measuring Device for Exhaust Gas Components of Internal Combustion Engines Based on Absorption Peak Locking Mode

A locking mode and exhaust gas technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of poor detection dynamic response, low detection accuracy, and complex exhaust gas characteristics of internal combustion engines, so as to achieve the effect of improving detection accuracy and avoiding detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is described in more detail below in conjunction with accompanying drawing example:

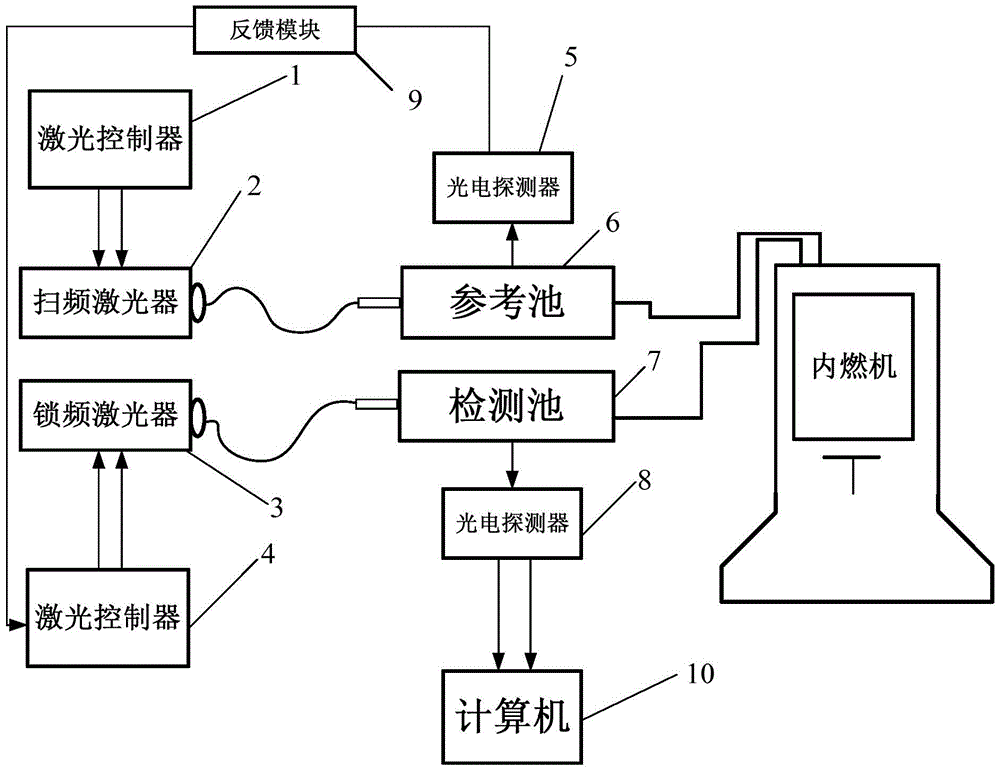

[0009] combine figure 1 , the present invention is a kind of internal combustion engine exhaust gas component measuring device based on the absorption peak locking mode, comprising No. 1 laser controller 1, sweeping frequency laser 2, frequency locking laser 3, No. 2 laser controller 4, No. 1 photodetector 5, reference pool 6, detection pool 7, No. 2 photodetector 8, feedback module 9 and signal processing system 10;

[0010] The gas discharged from the internal combustion engine is divided into two paths, one path enters the reference pool 6, and the other path enters the detection pool 8;

[0011] No. 1 laser controller 1 controls the frequency-sweeping laser 2, so that the frequency-sweeping laser 2 outputs a laser signal with periodic wavelength conversion, the laser signal passes through the reference cell 6, and the photodetector 5 detects the spectrum of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com