Method for omnibearing detection of defect of PET bottle cap antitheft ring

A detection method and technology of anti-theft ring, applied in the direction of optical testing flaws/defects, etc., can solve the problems of disconnection of bridging points, affecting detection accuracy, blind spots of viewing angles, etc., to eliminate differences in imaging posture, improve imaging quality, and reduce hardware. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the present invention, but are not used to limit the scope of the present invention.

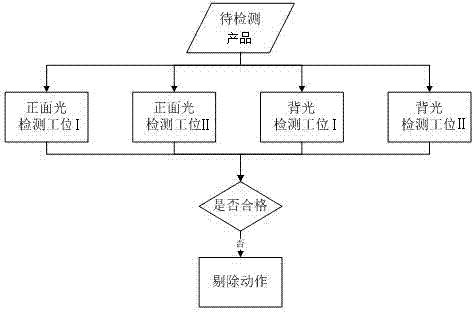

[0027] A method for detecting defects in an all-round PET bottle cap anti-theft ring, comprising the following steps:

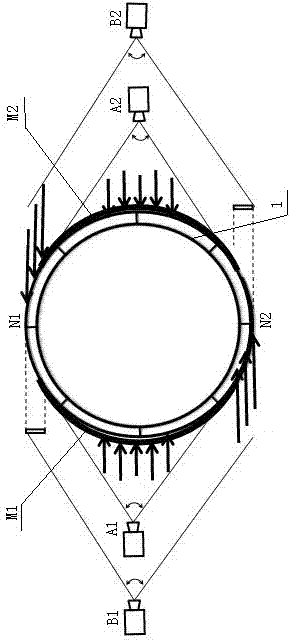

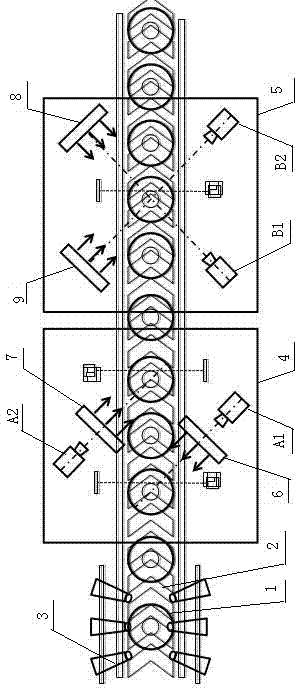

[0028] Step 1. Move the PET bottle to be tested through the conveyor belt 2, pass through the front light detection station I and front light detection station II of the first detection cabinet 4, and the backlight detection station I and backlight detection station of the second detection cabinet 5. Bit II, such as figure 2 The omnidirectional detection device of the present invention is shown in the structure diagram. Front light detection station I includes camera A1 and light source I6, front light detection station II includes camera A2 and light source II7, backlight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com