Surface mount coil unit and application thereof

A coil unit and adhesion technology, which is applied in the direction of transformer/inductor coil/winding/connection, electrical components, printed circuits connected with non-printed electrical components, etc., can solve the problem of unable to reduce costs, increase manufacturing costs, and affect production efficiency etc. to achieve the effects of low cost, simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

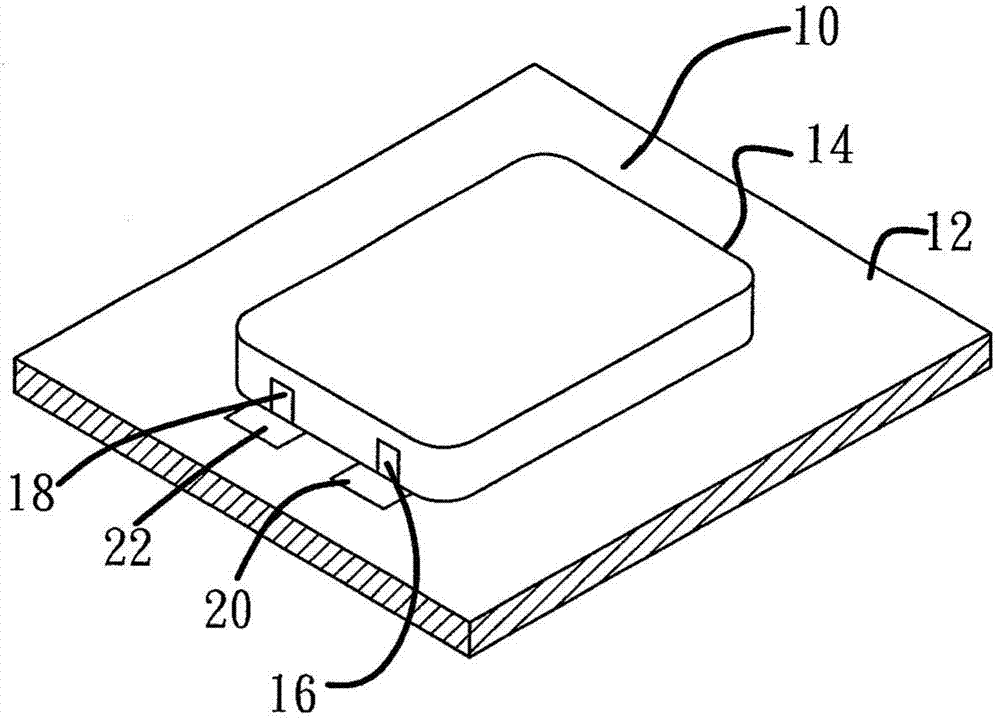

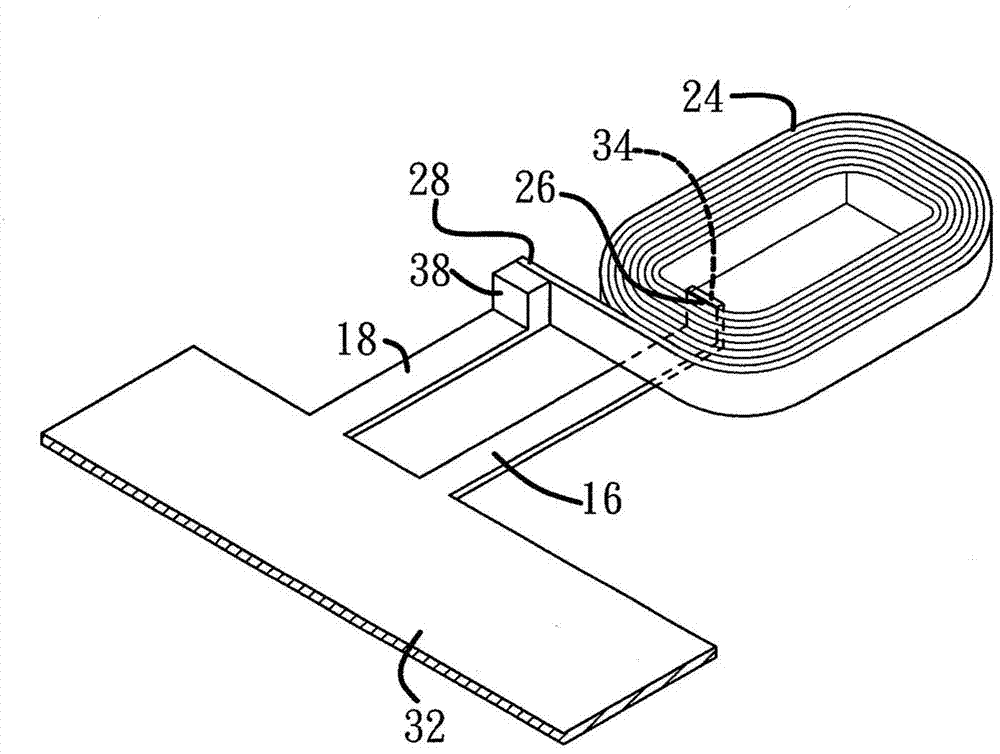

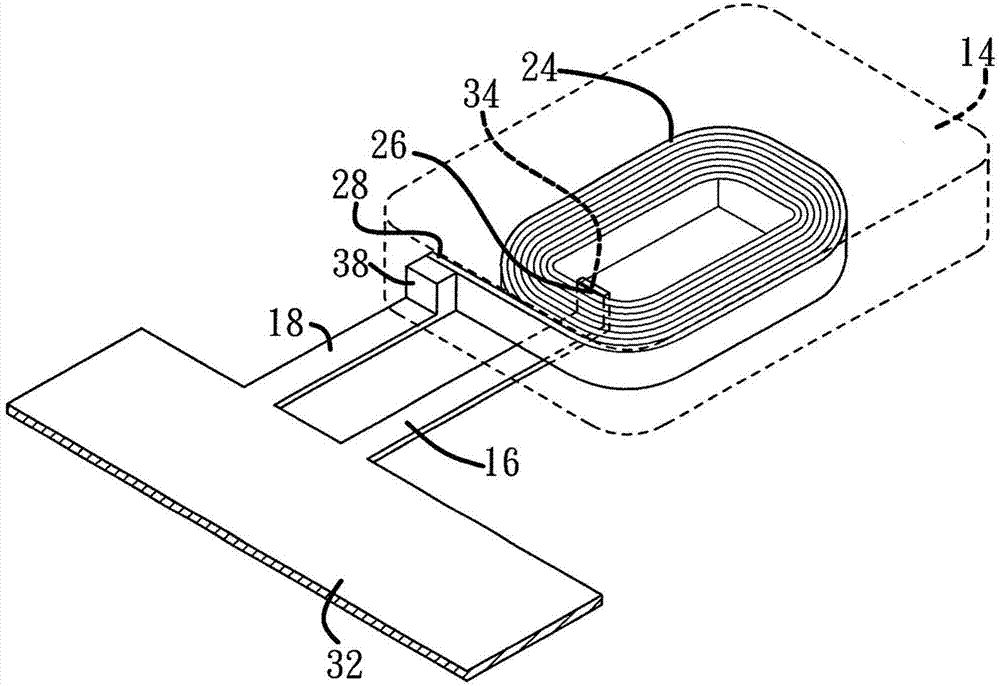

[0067] The surface mount coil unit of the present invention, such as figure 2 , Figure 3A , Figure 3B As shown, the coil unit 100 is attached to the surface, and a substrate 100A is provided at the bottom. The substrate 100A can be made of a magnetic material or a non-magnetic material. A magnetic material layer 103 is provided on the upper surface 100B of the substrate 100A. The lower surface of the substrate 100A is provided with a conductive pattern 100C, and the two opposite ends of the substrate 100A are respectively provided with a conduction hole 101, 102 for conducting the upper and lower electrodes. body 101A, 102A, the conductors 101A, 102A are in communication with the conductive pattern 100C on the lower surface of the substrate 100A.

[0068] As shown in the figure, a conductor coil 104 with an insulating layer on the surface is provided above the magnetic material layer 103 of the substrate 100A. The conductor coil 104 has a multi-layer spiral coil, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com