Method for improving coating cure for article coated in phosphate-contaminated electrocoat coating composition and electrocoat coating composition

A technology of ion pollution and composition, applied in the direction of electrolytic coating, electrophoretic coating, coating, etc., can solve the problems of wasting time, poor filter loading, rough appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

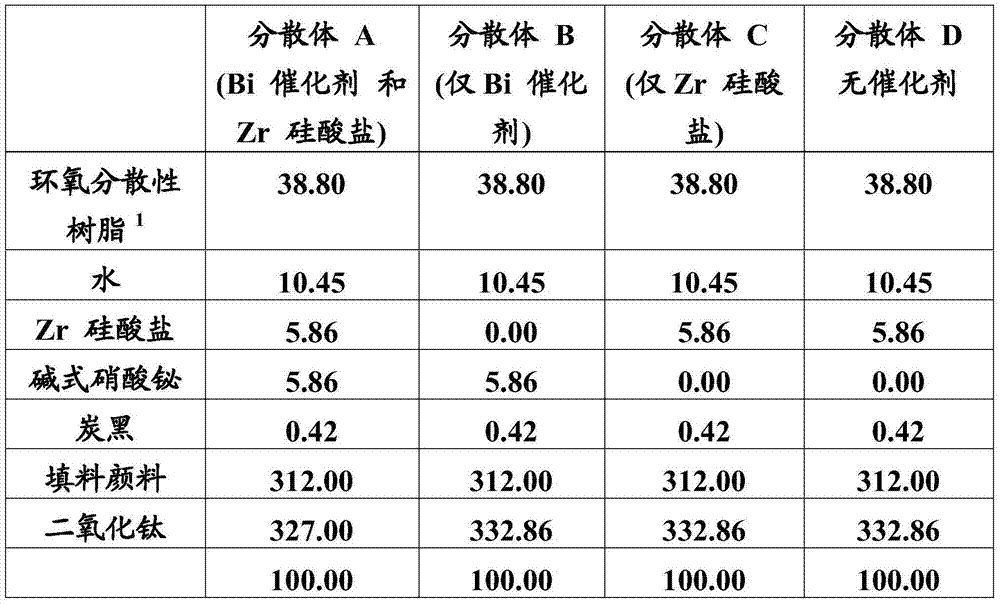

[0061] Preparation of dispersion

[0062] Dispersions A-D were prepared with the following compositions. Parts are by weight.

[0063]

[0064] 1. Aqueous Dispersion of Salted Amine Functional Epoxy Resin

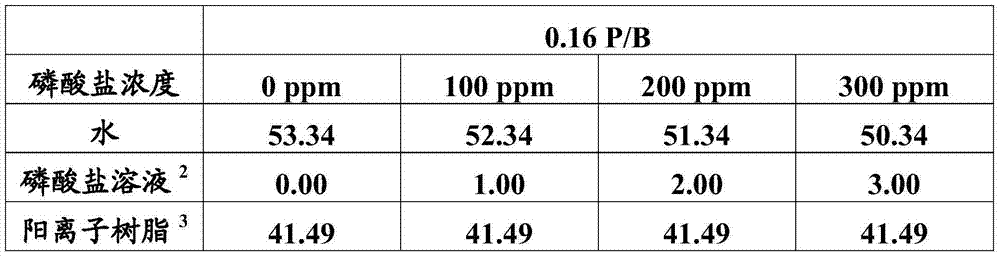

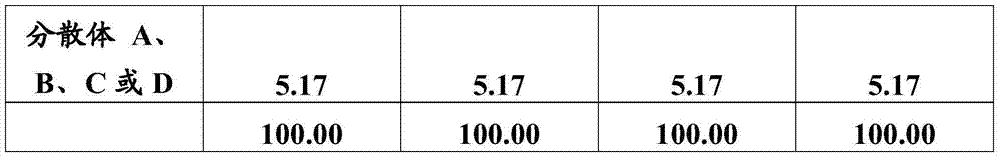

[0065] Preparation of Electrocoating Coating Compositions

[0066]

[0067]

[0068]

[0069] 2. The phosphate solution is a commercial phosphate treatment obtained from an automobile assembly plant

[0070] 3. A 40% aqueous dispersion of lactated amine functional epoxy resin having 27% by weight of amine functional epoxy resin, 12% by weight of blocked isocyanate crosslinker and 2% by weight of plasticizer.

[0071]The curing response of the electrocoat coating composition was tested by the Gel Fraction Test Method according to the following procedure.

[0072] 1. Weigh and record the mass of a 1" x 4" phosphated steel disc (A).

[0073] 2. Electrocoat the wafer and cure using the desired cure program.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com