Drying device capable of keeping original shape of dried golden camellia flowers

A drying equipment and technology of camellia japonica, which is applied in tea treatment before extraction, etc., can solve the problems that the style and stalk of camellia japonica can not be completely dried, the outer ring of petals is over-dried, and the color is affected, so as to achieve precise control of drying quality and efficiency, The effect of accelerating the drying speed and shortening the time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

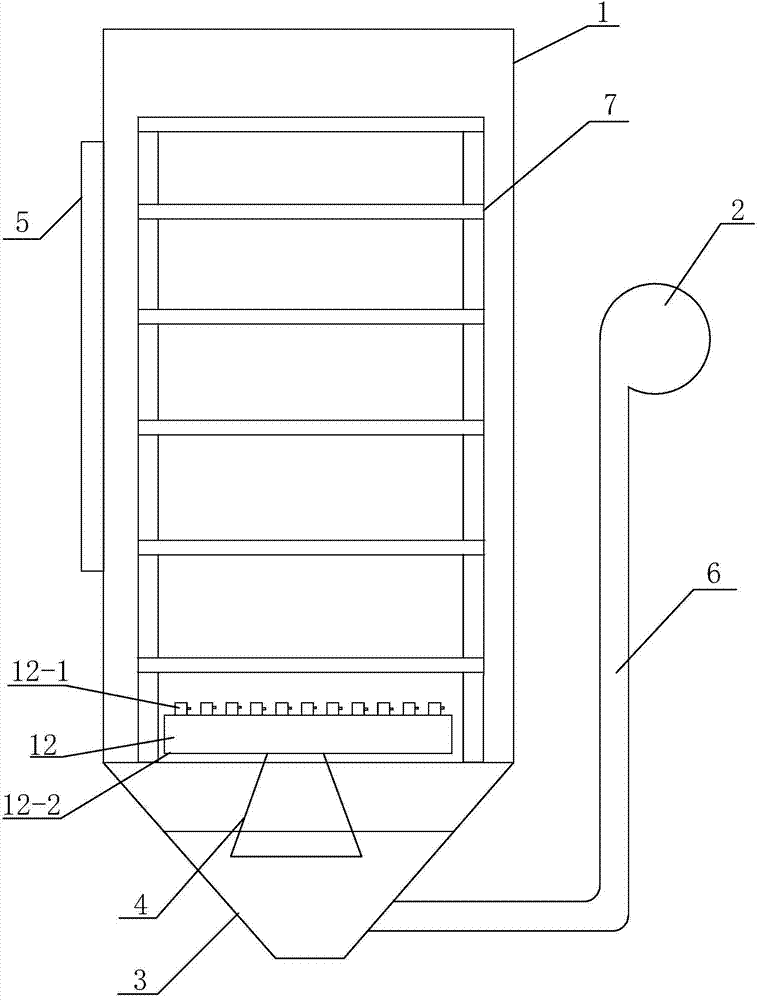

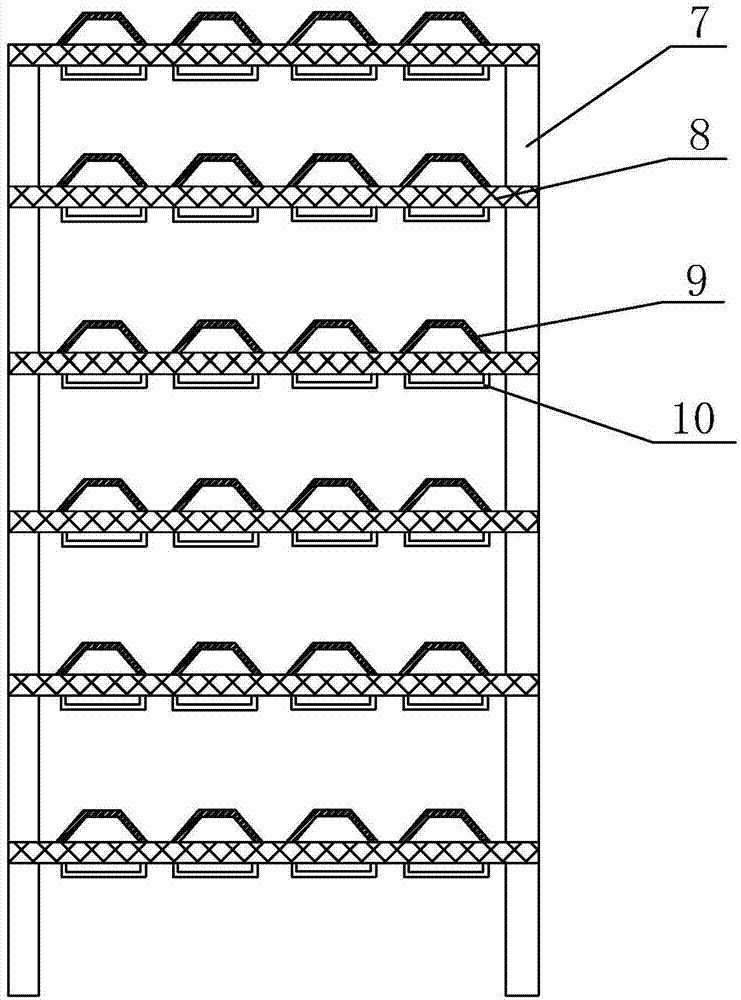

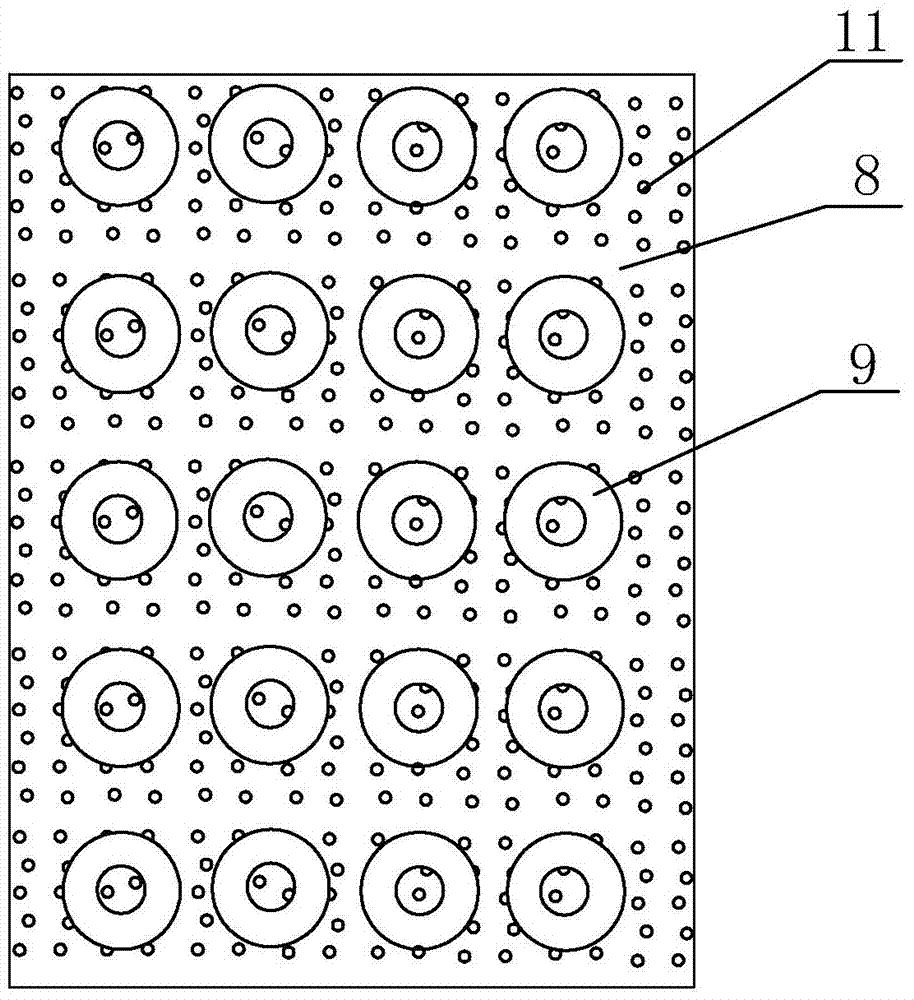

[0016] Such as figure 1 As shown, it is a drying device for keeping the original state of dried camellia camellia flowers according to the present invention, including a drying chamber 1 , a heating chamber 2 , a screen protector 3 , a hole screen device 4 and a control box 5 . The screen protector 3 is arranged at the lower part of the drying chamber 1 and is connected to the air inlet of the drying chamber 1. The screen protector 3 is connected to the heating chamber 2 through the hot air pipe 6. The screen protector 4 is arranged on the screen protector 3 Inside. The left side of described drying chamber 1 is equipped with the control box 5 that is used to control heating chamber 2 and drying chamber 1 working state, and the front of drying chamber 1 is made of transparent plate, is convenient to observe the drying situation of Camellia japonica flowers, in drying chamber 1 A flower holder 7 for supporting Camellia camellia flowers to prevent serious deformation during dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com