Heating furnace with obliquely-arranged coil pipes

A technology for heating furnaces and coils, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., and can solve problems such as the difficulty of medium discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

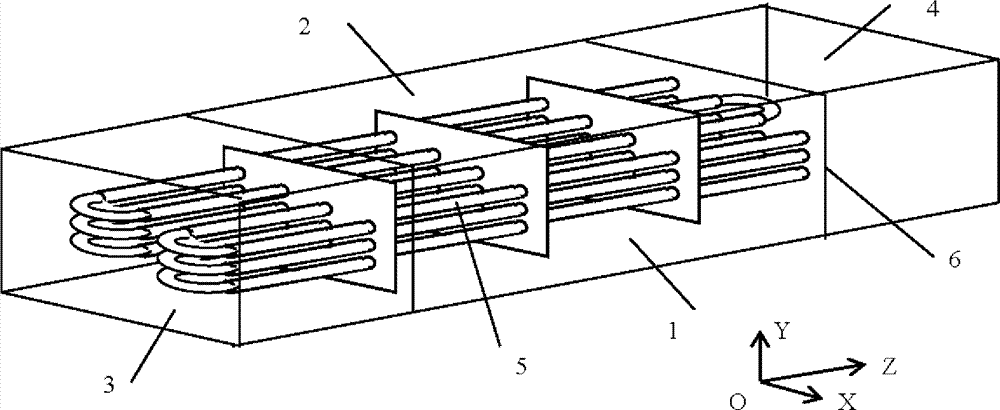

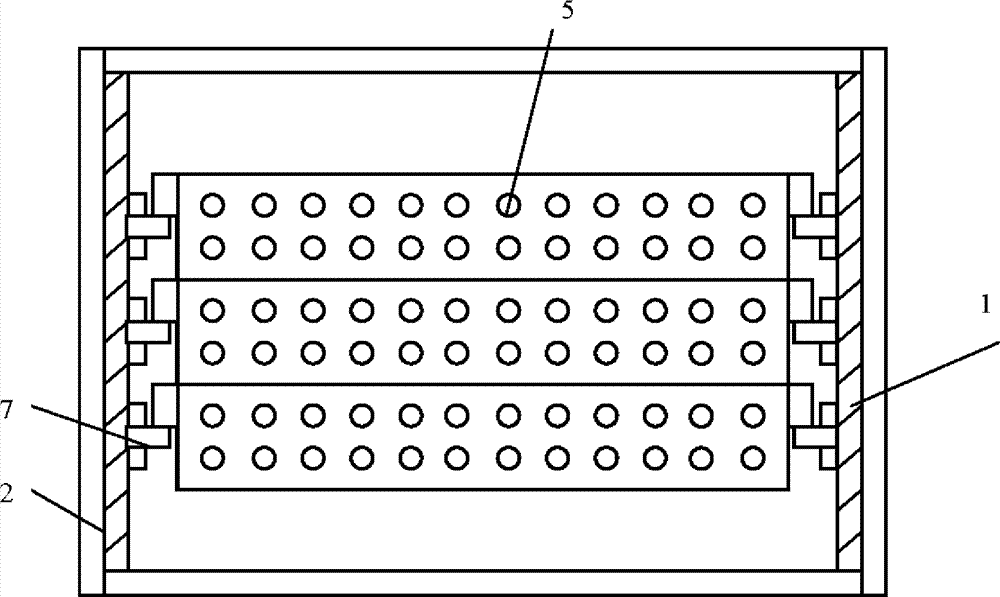

[0055] One of the specific implementations of a slanted coil heating furnace of the present application, according to the variation range of the heat exchange coil temperature in the flue gas flow, each heating furnace is divided into several heat exchange coil modules, stacked The heat insulation and heat preservation furnace walls around all the heat exchange coil modules together can be a whole large furnace wall, or can be independent small furnace walls of each heat exchange coil module. One is a cuboid assembly module.

[0056] The difference from the above-mentioned prior art is that all or part of the furnace tubes in the heat exchange coil module are arranged obliquely downward from the direction of the medium entering the coil 5 to the direction of the medium flowing out of the coil 5 . This application aims at the low energy consumption of the medium flow in the super-long furnace tube of the heating furnace and the difficulty in discharging the flammable and explos...

Embodiment 2

[0058] The second specific implementation mode of a kind of inclined coil heating furnace of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, in This will not be repeated here. The difference between this embodiment and Embodiment 1 is that the traditional vertical column in the prior art is designed with a certain inclination, so that the overall furnace tube in the heat exchange coil module enters the direction of the coil 5 from the medium The direction until the medium flows out of the coil pipe 5 is arranged obliquely downward. The inclined column makes the module support into an inclined structure with one end high and the other end low during installation. When the column returns to the vertical vertical position, the coil 5 in the module will also passively form a structure with one end high and the other end low. incline...

Embodiment 3

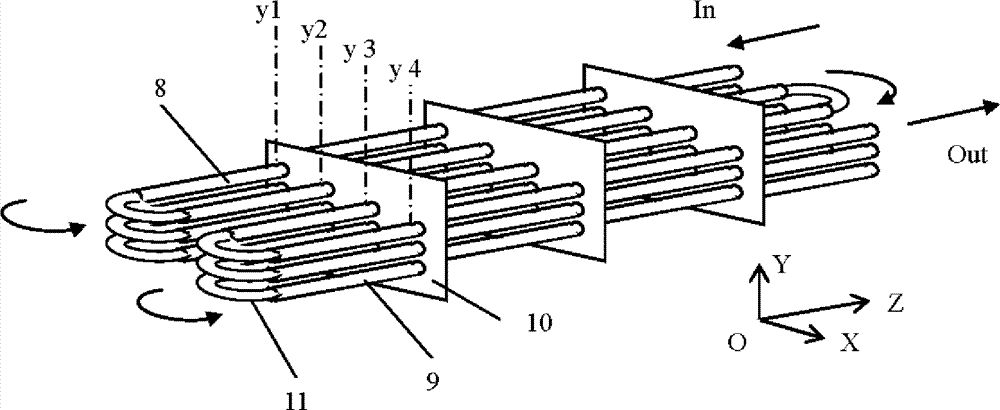

[0061] The third specific embodiment of a slanted coil heating furnace of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are explained in embodiment 1. This will not be repeated here. The difference between this embodiment and Embodiment 1 is that the furnace tubes located at the same height in the same process in the heat exchange coil module and the coils 5 whose two ends are connected in series through elbows 11, in the coils 5 The furnace tubes are arranged obliquely downward from the direction in which the medium enters the coil 5 to the direction in which the medium flows out of the coil 5 . For details, see image 3 with Figure 4 As shown, in addition to the components mentioned in Embodiment 1, it also includes a furnace tube 8 along the horizontally higher side, a furnace tube 9 along the laterally lower side, a tube plate 10 and an elbow 11 . Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com