Annular tooth seam supersonic jetting nozzle

A technology of jet nozzle and ring tooth gap, which is applied in the field of supersonic jet nozzle of ring tooth gap, which can solve the problems that the nozzle material affects the area of the ring gap, affects the injection flow rate, and the oxygen blowing flow is limited, so as to prevent the gun from being blocked and improve the efficiency. , the effect of high working gun position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0043] The directions mentioned in this embodiment take the direction from back to front as the spraying direction.

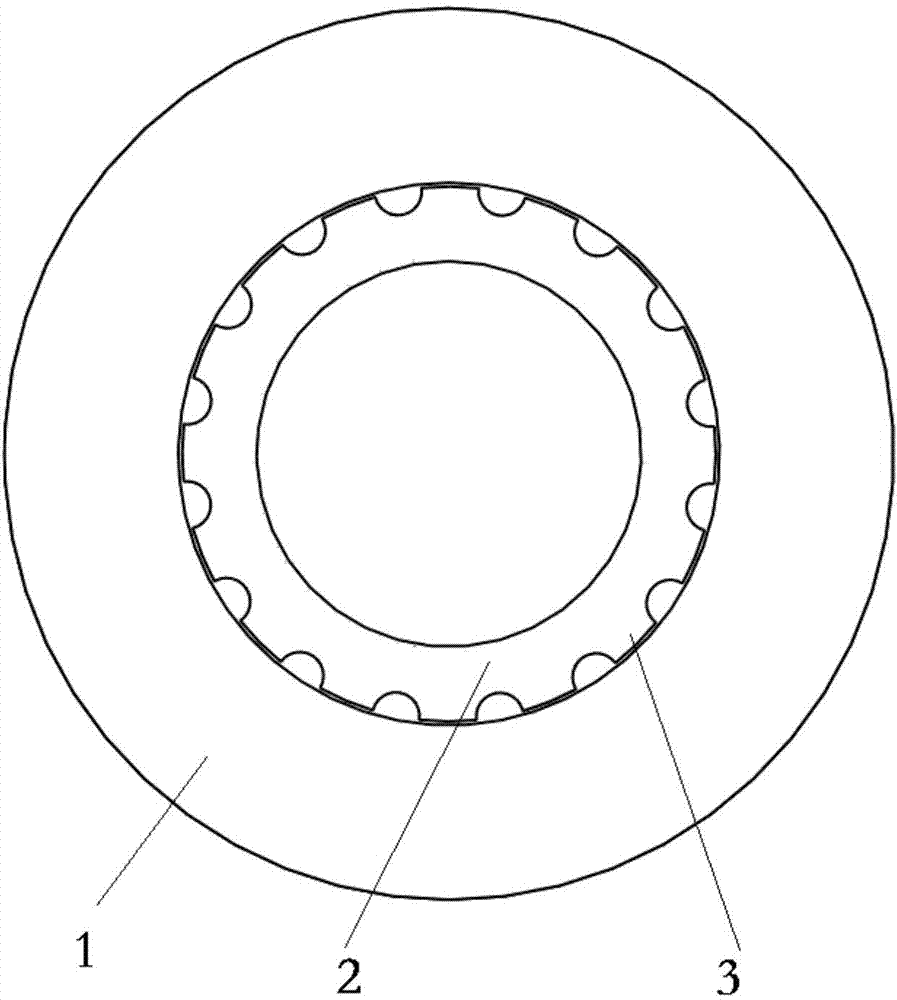

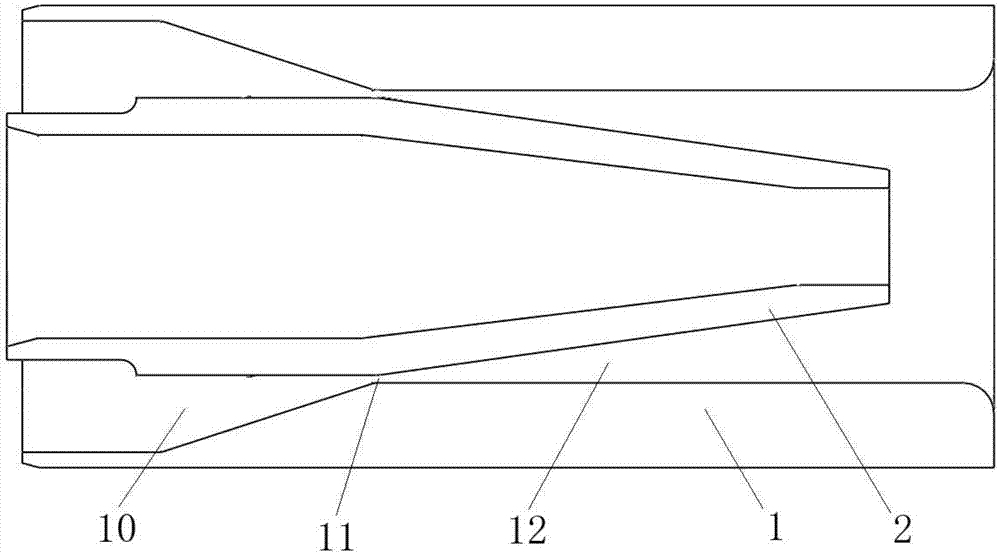

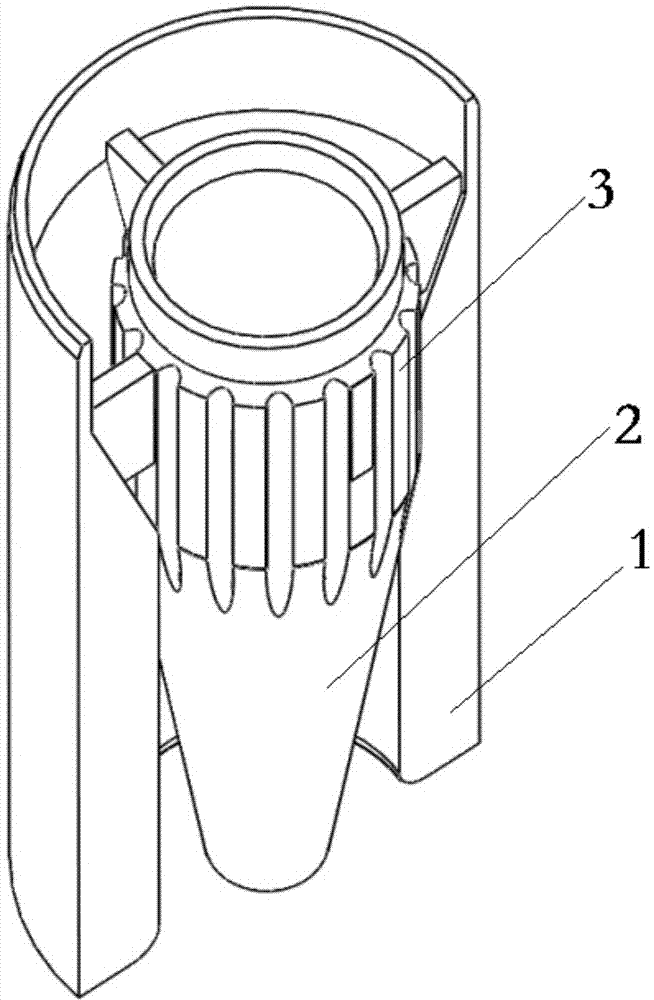

[0044] Such as Figure 1 to Figure 3 As shown, the present invention provides a ring-tooth supersonic jet nozzle, comprising a coaxially arranged hollow core tube 2 and a variable-section outer tube 1, the hollow core tube 2 is located inside the outer tube 1, and the inner surface of the outer tube 1 is aligned with the hollow Between the outer contour surfaces of the core tube 2, three sections of variable-section passages are formed in sequence along the axial direction: the annular constriction section 10, the throat section 11 and the annular expansion section 12, wherein the cross section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com