An electrolytic triple monomer module for purification of precious metals

A precious metal, monomer technology, applied in the direction of cells, etc., can solve the problem of no large-scale application, and achieve the effect of improving efficiency, reducing investment and production costs, and reasonable structural composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

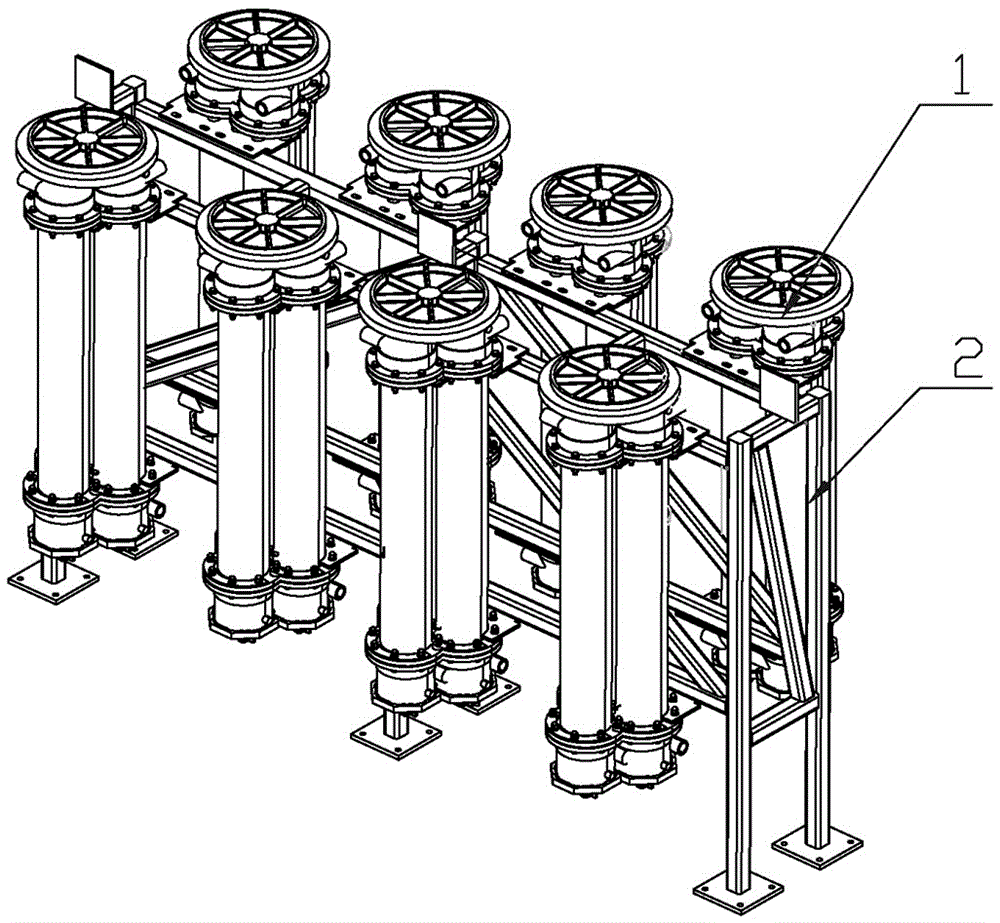

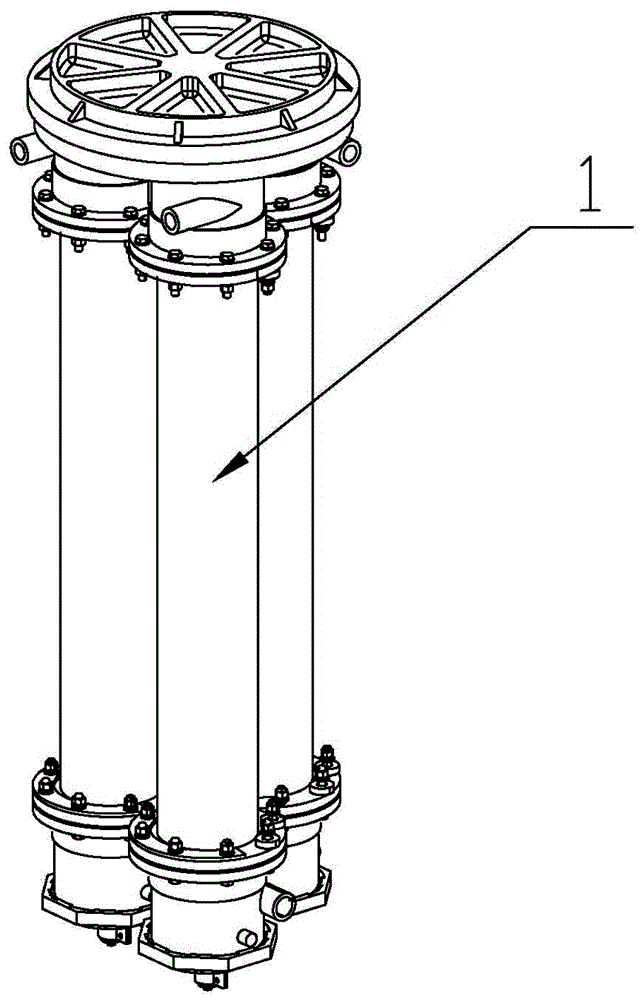

[0026] Embodiment: The following will take 2 X 4 triple monomers as an example and combine Figure 1-6 , to further specifically describe the technical solution of the present invention: the present invention mainly consists of a triple monomer 1 and a bracket 2 . The support 2 is designed as an integral support device according to the 2 X 4 triple monomer electrolysis system, and four triple monomers 1 are fixedly installed on the left and right sides, and their supporting circulation pipelines.

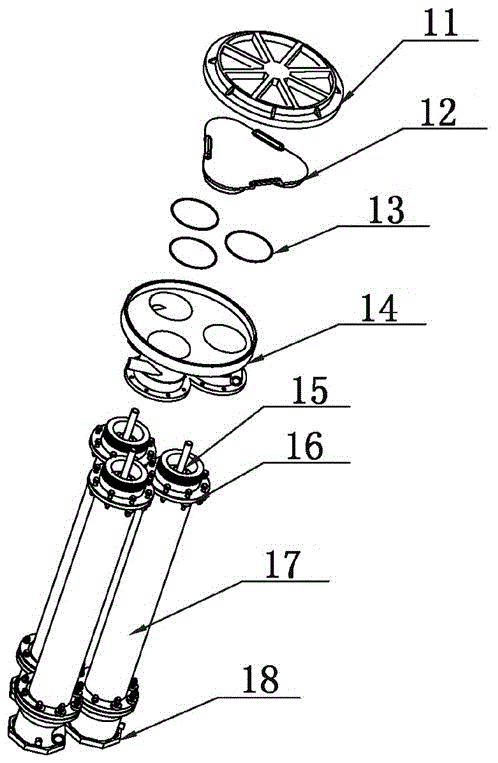

[0027] The triple monomer 1 is installed vertically and consists of three tanks 16; the upper part of the three tanks 16 of the triple monomer 1 is sequentially installed with an upper connector 14, a sealing ring 13, a gland 12, an upper end Cover 11 to form a sealed electrolyzer. The upper connector 14 and the lower connector 18 are installed and fixed with three tank bodies 16 to form a triple unit 1 .

[0028] The material of the tank body 16 is titanium metal, and the wall th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com