Assembled semi-rigid wood structure joint

A semi-rigid, wood structure technology, used in building components, building structures, earthquake resistance, etc., can solve the problem of limited bending bearing capacity and rotational stiffness of joints, which can only be used in simply supported or hinged situations, and difficult to design, construct and install. Competency and other issues, to achieve the effect of reducing maintenance and repair costs, high practical value and economic value, and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

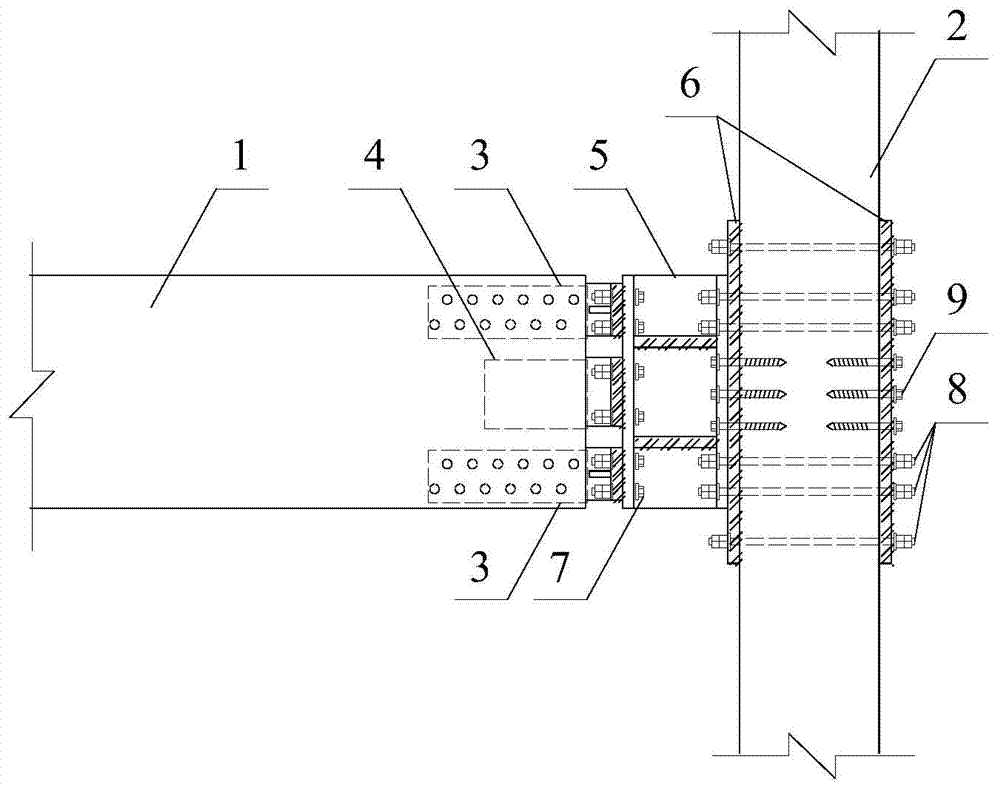

[0032] like Figure 1-8 Shown: a prefabricated semi-rigid wood structure node, including component one 1, component two 2, bending connector 3, shear connector 4, assembly 5, steel backing plate 6 and connecting bolt 7;

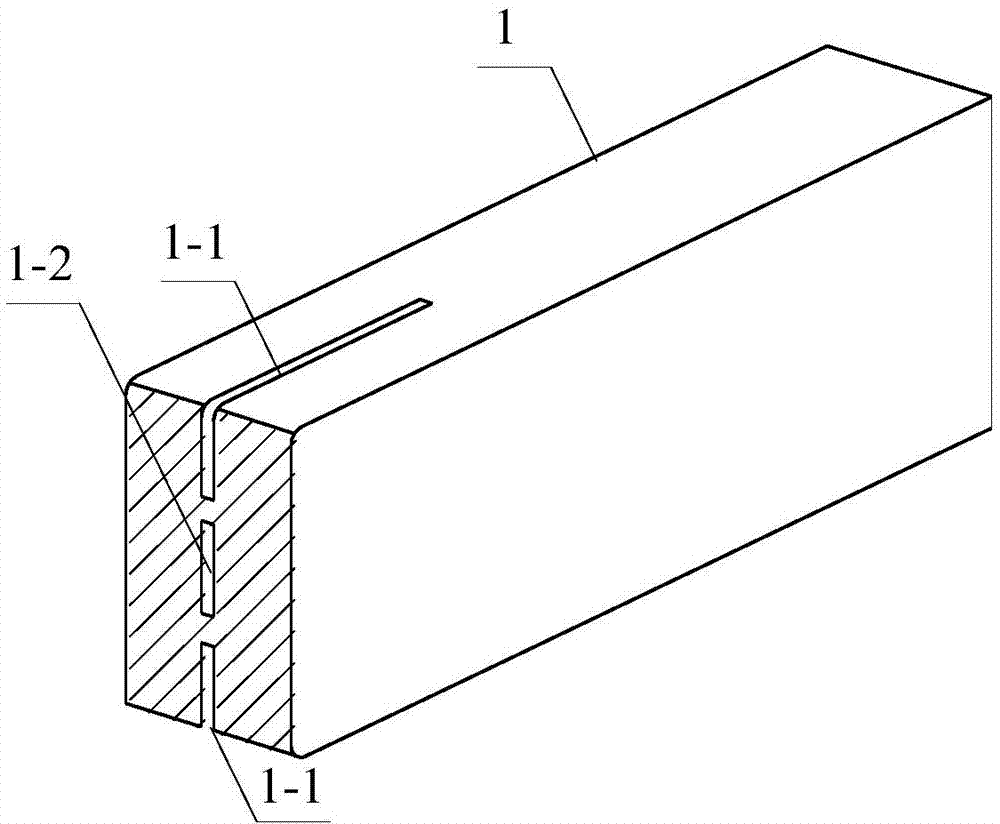

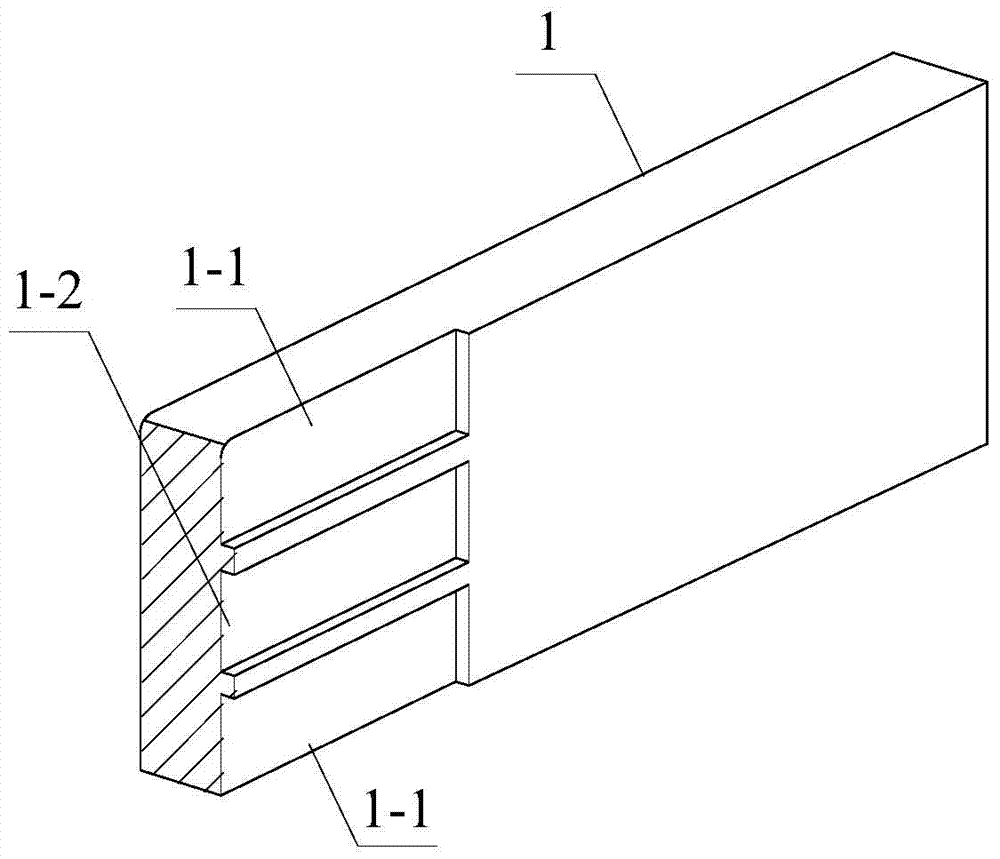

[0033] The member one 1 is a wooden member, the bending connector 3 and the shear connector 4 are fixed to the end of the member one 1 by planting steel plates, and the bending connector 3 and the shear connector 4 are T-shaped steel 3-1, the rubber layer is vulcanized on the surface of the implanted wooden component part, and the end of component 1 is pre-grooved on the planting steel plate, and the pre-grooving includes pre-grooving 1-1 on the top and bottom of the component and pre-grooving 1-1 in the center of the component. 2, respectively corresponding to the bending connector 3 and the shear connector 4, the bending co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com