Radial multi-layer magneto-rheological clutch

A magnetorheological and clutch technology, used in fluid clutches, clutches, mechanical equipment, etc., can solve the problems of difficult disassembly and replacement of coils, small transmission torque, large axial size, etc., to achieve compact structure and increase magnetic field strength. , the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

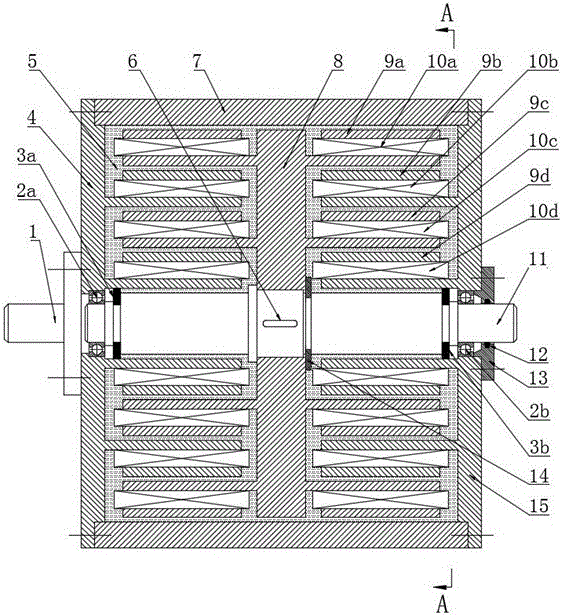

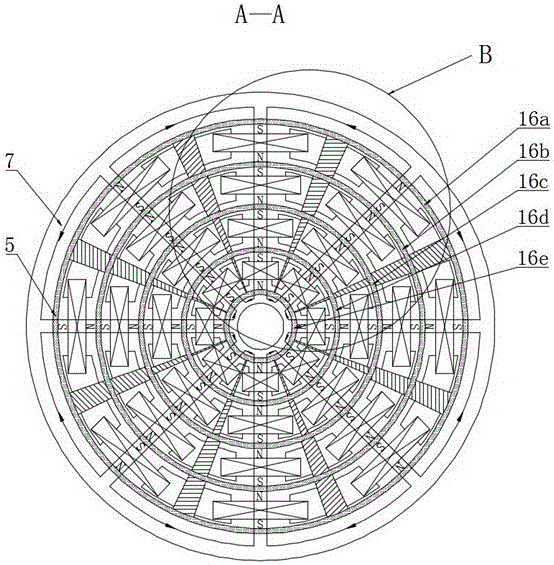

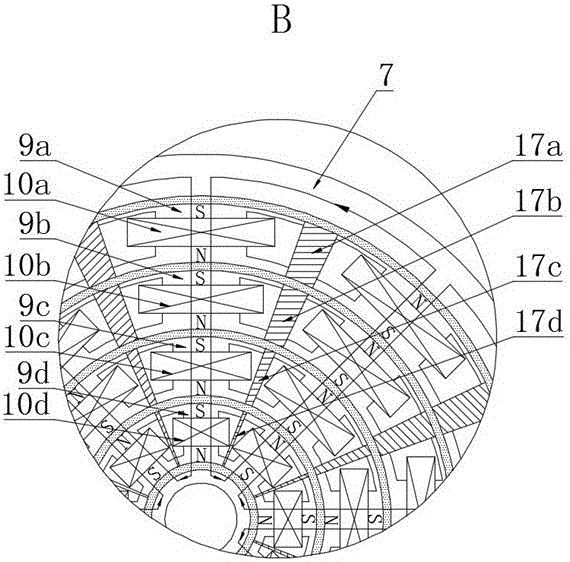

[0029] combined with figure 1 , figure 2 , image 3 As shown, the radial multi-layer magneto-rheological clutch includes an output shaft 1, a left disc 4, a housing 7, a support disc 8, a rotor, a magnetorheological fluid 5, a coil, a right disc 15, an aluminum block and Input shaft 11, the rotor includes rotor I9a, rotor II9b, rotor III9c and rotor IV9d, the coil includes coil I10a, coil II10b, coil III10c and coil IV10d, and the aluminum block includes aluminum block I17a, aluminum block II17b, aluminum block III17c and aluminum block IV17d, the left disc 4, the right disc 15 and the casing 7 arranged between the left disc 4 and the right disc 15 form a cavity, and the output shaft 1 is fixedly connected to the outer surface of the left disc 4;

[0030] One end of the input sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com