Bellows parallel gate valve

A bellows and gate valve technology, applied in the field of bellows parallel gate valves, can solve the problems of poor interchangeability of parts, no cleaning, large operating torque, etc., and achieve the effects of strong interchangeability of parts, easy online maintenance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

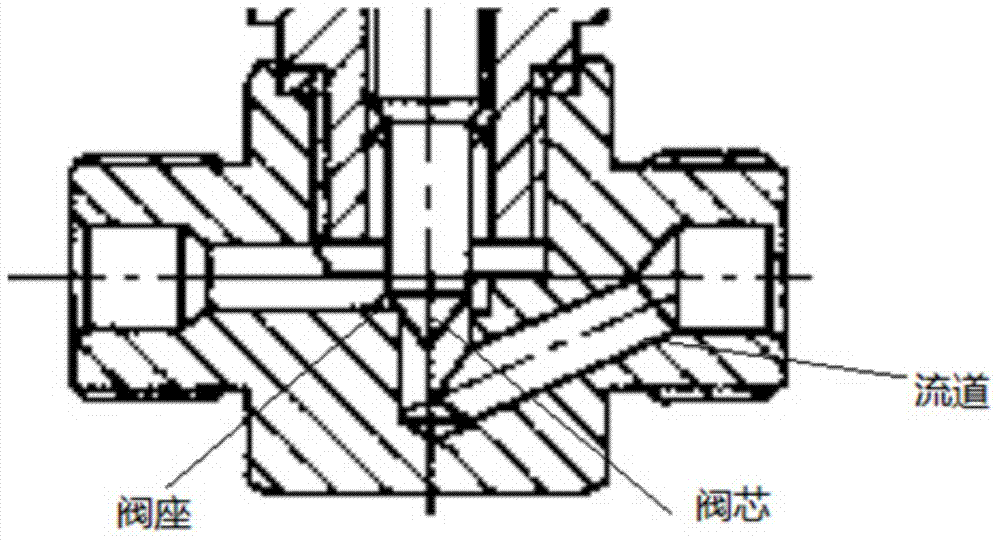

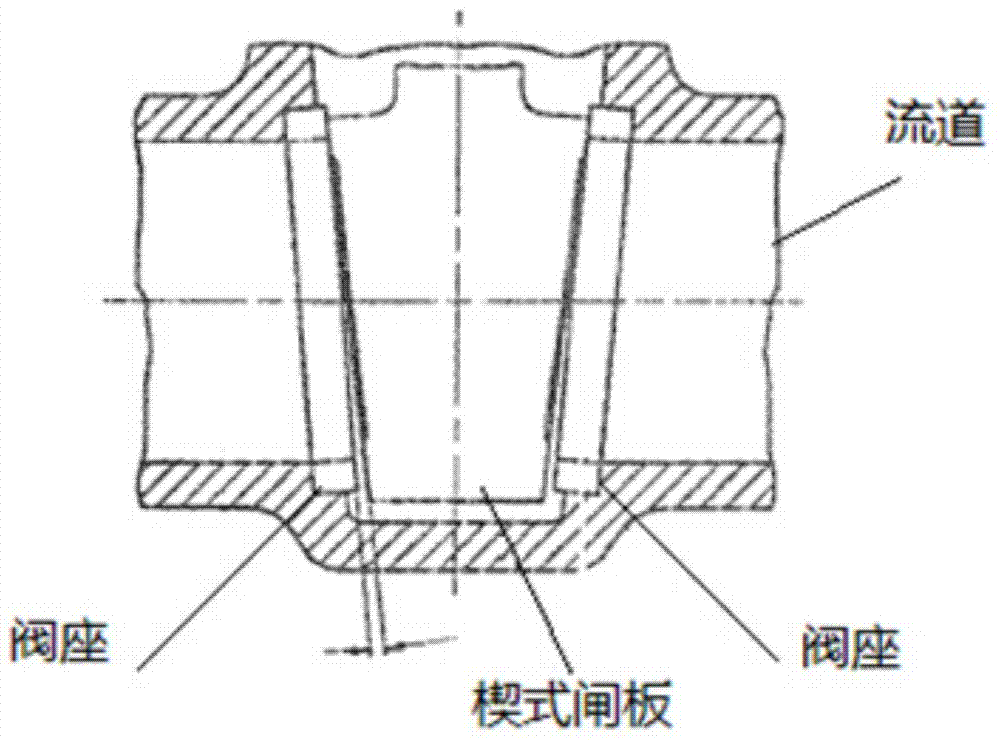

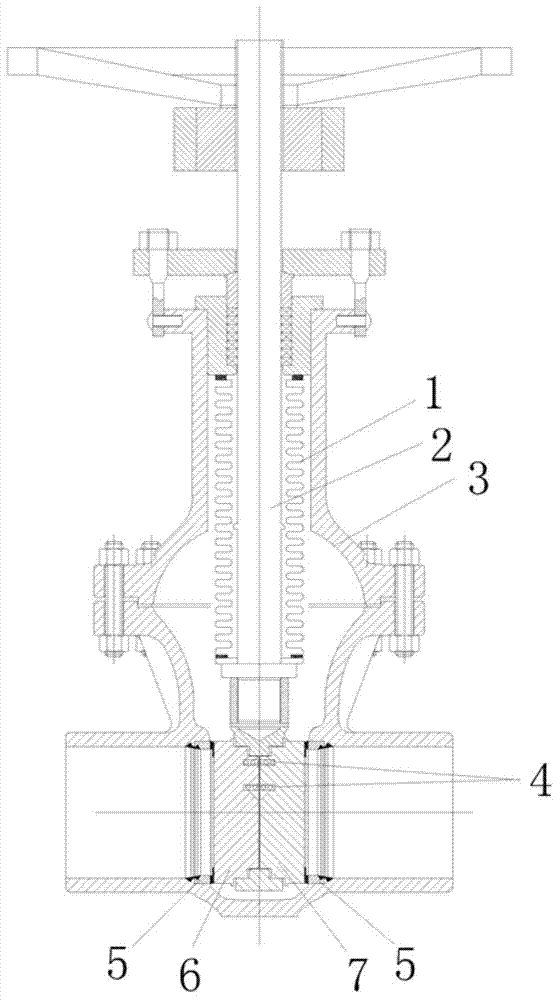

[0027] like image 3 The bellows parallel gate valve shown includes a valve body 3 and a bonnet, a valve stem 2 is set inside the valve body 3, the bellows 1 is set outside the valve stem 2, a valve core is set at the lower part of the valve stem 2, and a valve core is set inside the valve core. Horizontal flow channel, two parallel inlet rams 6 and outlet rams 7 are set on the flow channel, the two rams are perpendicular to the horizontal flow channel, two parallel return springs are set between the two rams, and the rams are against the on seat 5. The lower end of the valve stem 2 is arranged on the gate plate, and the upper end of the bellows 1 and the upper part of the valve stem 2 are filled with packing.

[0028] Compared with the bellows stop valve, the present invention has the following advantages:

[0029] 1. The bellows parallel gate valves are straight-through type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com