Self-compacting concrete mixture stability test device and test method for filling layer

A self-compacting concrete, stability testing technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of harsh performance and stability of self-compacting concrete, unable to evaluate the stability of self-compacting concrete mixture, etc., to achieve reliable performance , simple structure, ensure the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

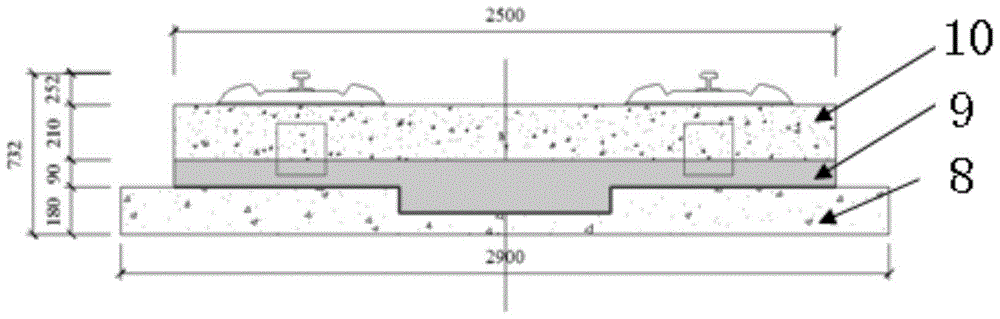

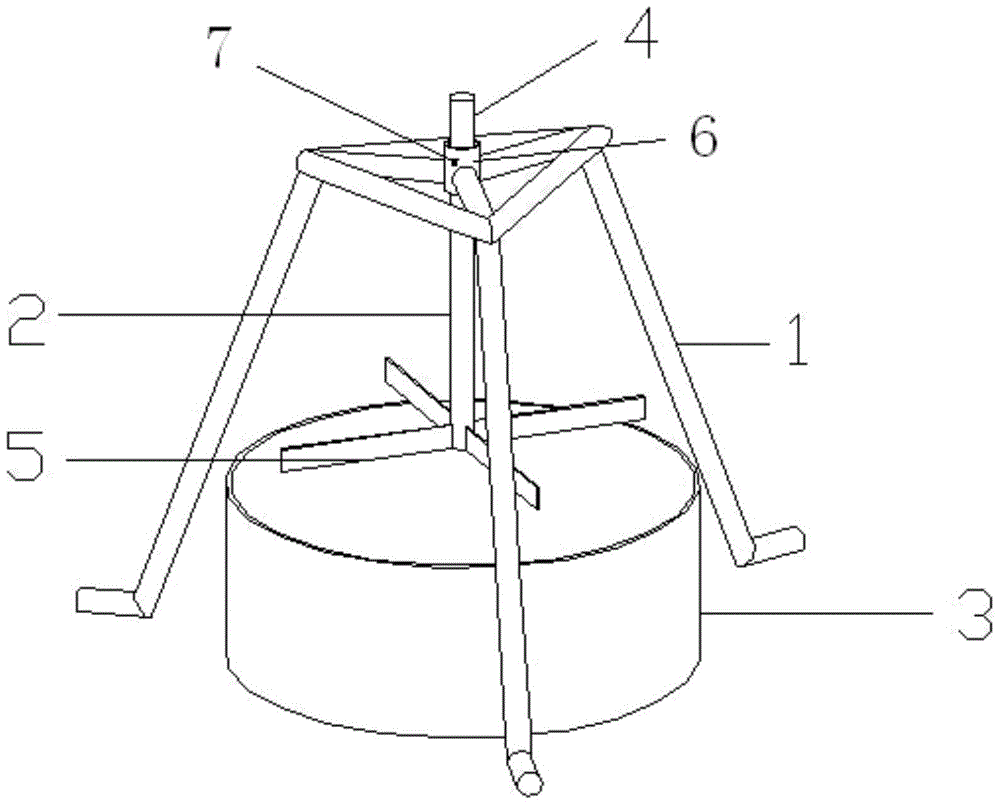

[0039] see figure 2 , The filling layer self-compacting concrete mixture stability test device is composed of a tripod support 1, a surface layer slurry thickness tester 2 and a stainless steel cylinder 3. The tripod support 1 is made of stainless steel, and the three legs form a Arranged at 120°, the height of the tripod 1 is 250mm, the lower horizontal distance between the three legs of the tripod 1 is 300mm, and the upper horizontal distance is 100mm, and the upper center of the tripod 1 is set with a hole diameter of Ф6mm and a length of 20mm. Conduit 6; the geometric dimensions of the stainless steel cylinder 3 are Ф200mm in diameter, 110mm in height, and 2mm in wall thickness. Rod 4 and 4 blades 5 are composed, and 4 blades 5 are welded and fixedly installed on the lower end of central rod 4. Adjacent blades 5 are arranged at 90° to eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com