Workpiece holder in ultrasonic testing equipment and positioning method

A workpiece fixture and testing equipment technology, which is applied in the direction of material analysis, measuring device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problem of inability to realize batch testing, and achieve the effect of ensuring accuracy and improving testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

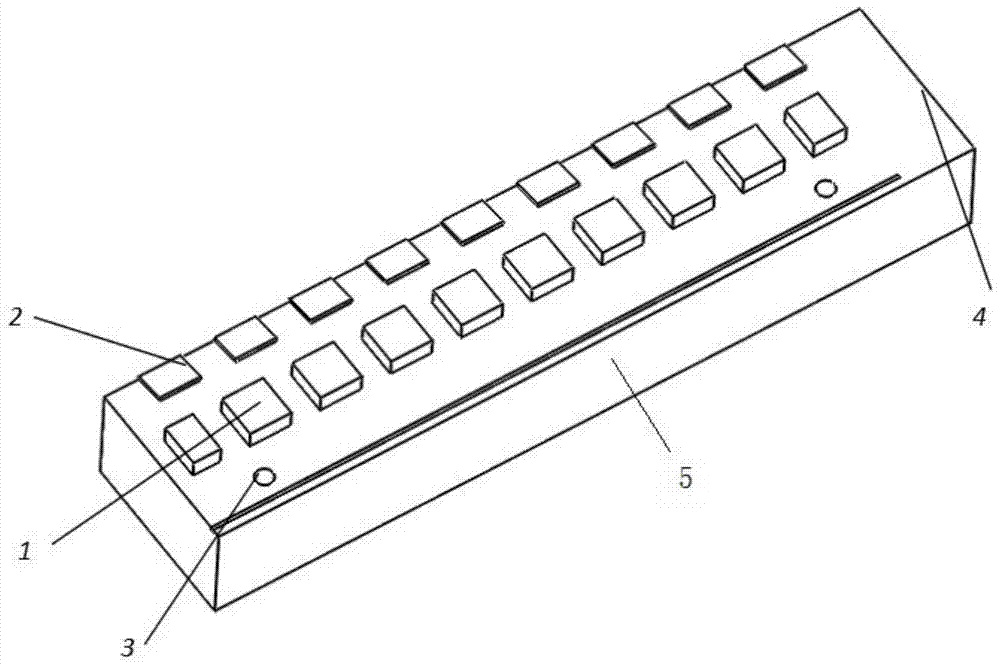

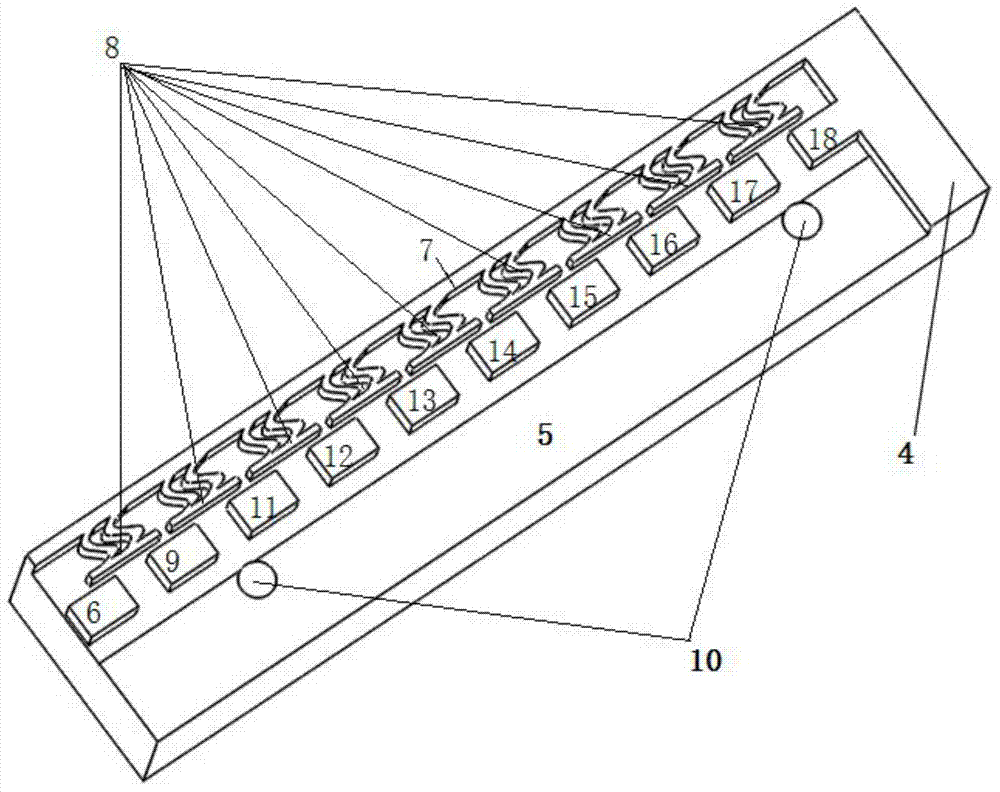

[0030] Such as figure 1 As shown, this embodiment provides a multi-station workpiece fixture in ultrasonic testing equipment, the fixture includes a multi-station workpiece clamping structure 1, a workpiece fixing structure 2, a fixture bottom positioning structure 3, a fixture numbering area 4 and a base 5, of which:

[0031] The multi-station workpiece clamping structure 1, that is, a plurality of bosses arranged in the middle of the base 5, is used to fix the left and right sides of the workpiece to be tested, so as to realize the batch detection of the workpiece to be tested and improve the detection efficiency. efficiency;

[0032] The workpiece fixing structure 2, that is, a plurality of elastic fixing pieces arranged at the tail of the base 5, is used to resist the tail of the workpiece to be measured and cooperate with the workpiece clamping structure 1 to ensure that the workpiece to be measured is stable and does not move;

[0033] The positioning structure 3 at th...

Embodiment 2

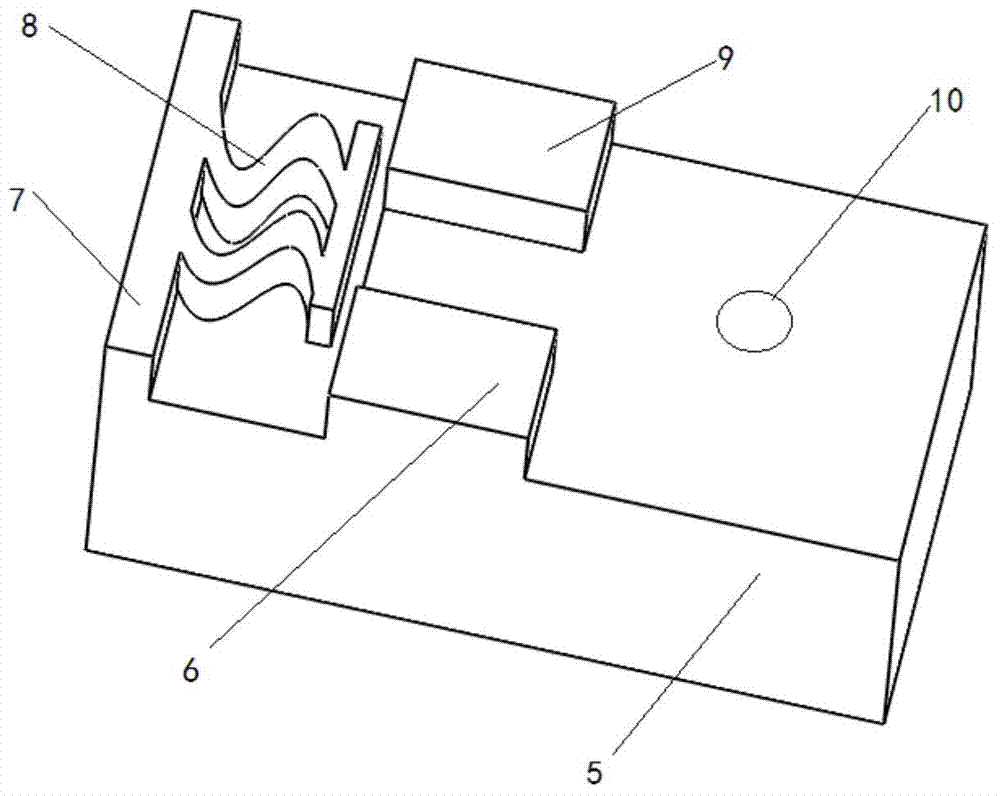

[0039] Such as figure 2 As shown, this embodiment provides another single-station workpiece fixture in ultrasonic testing equipment. The workpiece fixture includes: a base 5, fixed bosses 6, 9 arranged in the middle of the base 5, arranged on the The fixed boss 7 at the tail of the base 5, the supporting spring 8, and the positioning hole 10; wherein:

[0040] The base 5 is a cuboid, and the surface of the base 5 is larger than the lower surface of the workpiece to be measured; the fixed bosses 6, 9 are arranged in the middle of the base 5 and distributed symmetrically; the fixed bosses 6 and The height of 9 is 5mm; the fixed boss 7 is arranged on the tail of the base 5, and the height of the fixed boss 7 is the same as that of the fixed bosses 6 and 9; one end of the support spring 8 is fixed on the The upper and other ends of the fixed boss 7 are free; the positioning hole 10 is set at the center of the base 5 for overall fixing of the workpiece fixture.

[0041] When usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com