Electrical cabinet and heat dissipation control method thereof

A control method and technology of electrical cabinets, applied in the electrical field, can solve the problems of easily damaged components, cost-effectiveness, and system paralysis, and achieve the effects of improving cooling efficiency, reducing losses, and preventing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

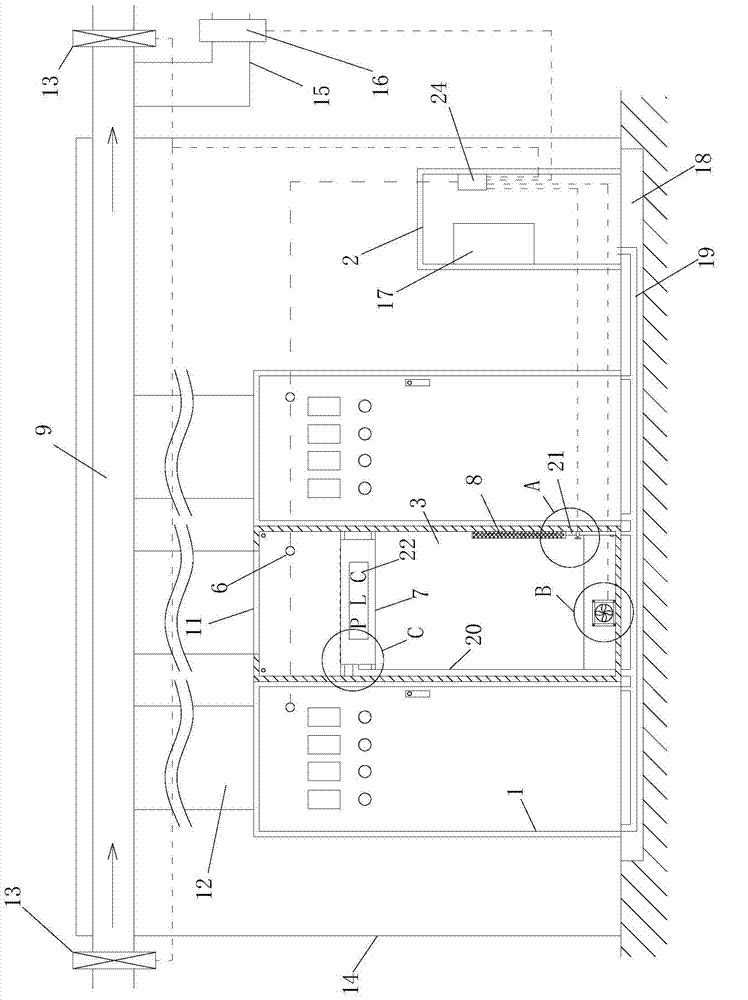

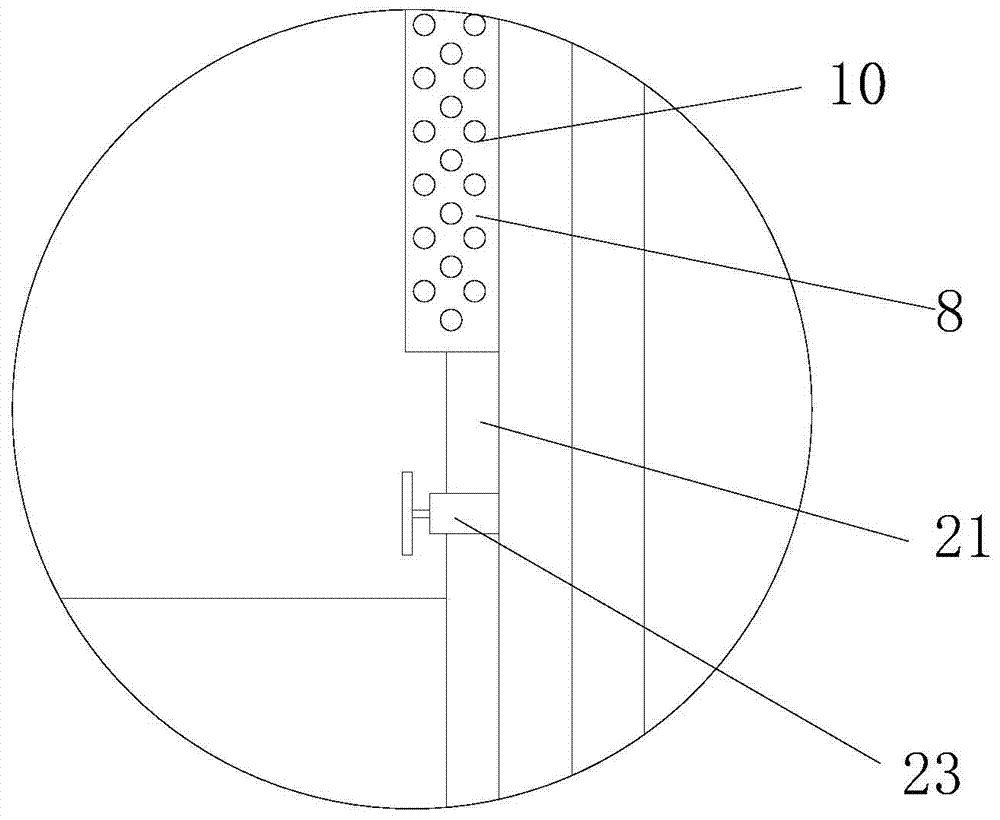

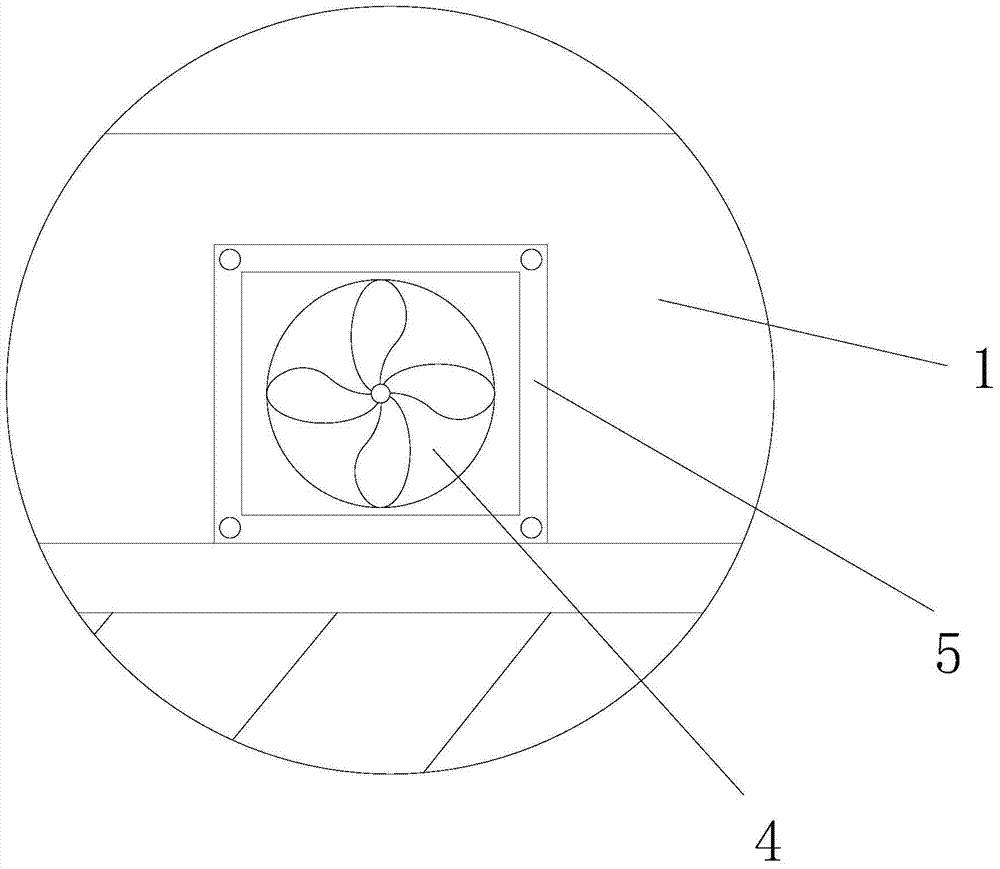

[0029] like figure 1 , 2 , 3, and 4, the electrical cabinet described in this embodiment includes several cabinets 1 and an air-conditioning cabinet 2 arranged side by side, wherein the number of cabinets 1 is generally 3-8 in a row, and of course it can be changed According to the actual situation, there is a mounting plate 3 for installing electrical components in the cabinet 1, an air inlet 4 is provided at the bottom of the cabinet 1, a fan 5 is provided on the air inlet 4, and a fan 5 is installed in the cabinet 1. There is a temperature sensor 6; a controller installation chamber 7 is arranged on the mounting plate 3, and the upper part of the controller installation chamber 7 has an overflow hole 25, and a cold air cover 8 is arranged on the inner wall of the cabinet body 1, and the cold air cover 8 The surface is covered with air outlet holes 10; an air duct 9 with both ends open is provided above the cabinet body 1, and the air outlet 11 at the top of each cabinet bo...

Embodiment 2

[0048] like Figure 5 As shown, the electrical cabinet described in this embodiment is different from Embodiment 1 in that the bottom surface of the air duct 9 is a structure with a high middle and low sides. Such a scheme can prevent rainwater from entering the air duct, so that rainwater cannot live in the center flow Prevent rainwater from entering the cabinet body 1.

[0049] Also can be provided with some rows of water retaining rods on the bottom surface of air duct 9 and carry out waterproofing.

Embodiment 3

[0051] like Figure 6 As shown, the electrical cabinet described in this embodiment includes several cabinets 1 and an air-conditioning cabinet 2 arranged side by side, wherein the number of cabinets 1 is generally 3-8 in a row, and of course there can be more, depending on the actual situation Depending on the situation, a mounting plate 3 for installing electrical components is provided in the cabinet body 1, an air inlet 4 is provided at the lower part of the cabinet body 1, a fan 5 is provided on the air inlet port 4, and a temperature sensor 6 is also provided in the cabinet body 1 ; A controller installation chamber 7 is provided on the installation plate 3, and the upper part of the controller installation chamber 7 has an overflow hole 25, and a cold air cover 8 is provided on the inner wall of the cabinet body 1, and the surface of the cold air cover 8 is covered with outlets. Air holes 10; an air duct 9 with open ends is provided above the cabinet body 1, and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com