Radio frequency pesticide and sterilization continuous treatment device

A technology of insecticide and treatment equipment, which is applied in the fields of seed preservation through radiation/electrical treatment, food preservation, food science, etc. It can solve the problems of uneven insecticide and sterilization, save energy, maintain material quality, and improve processing speed and the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

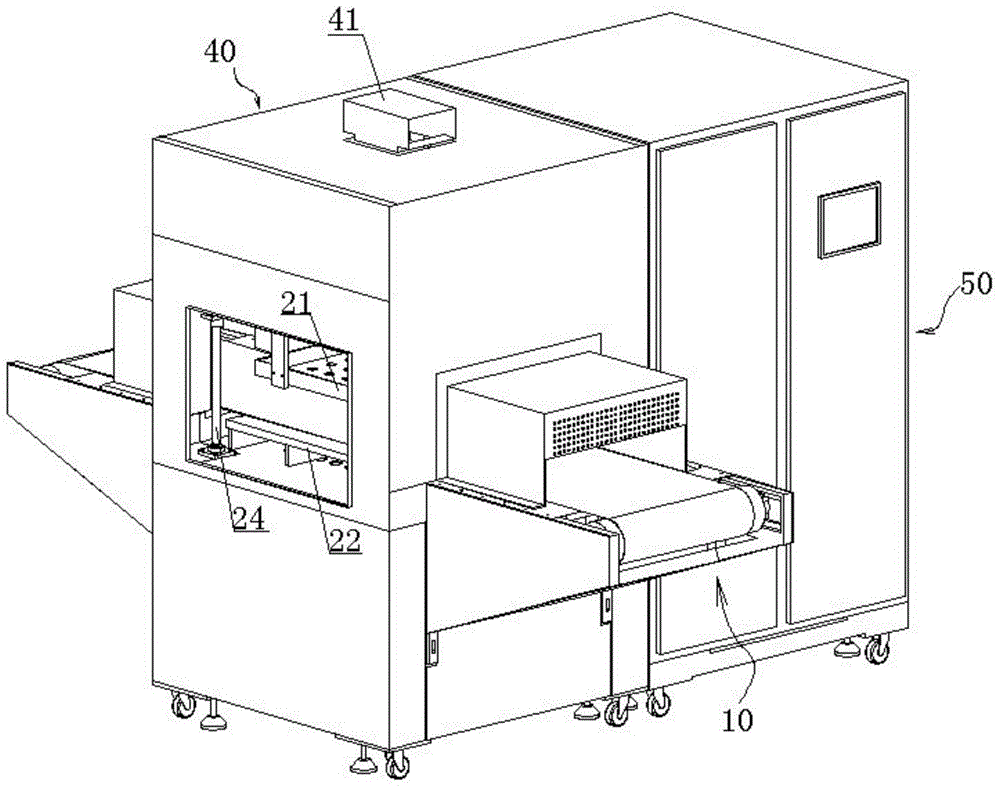

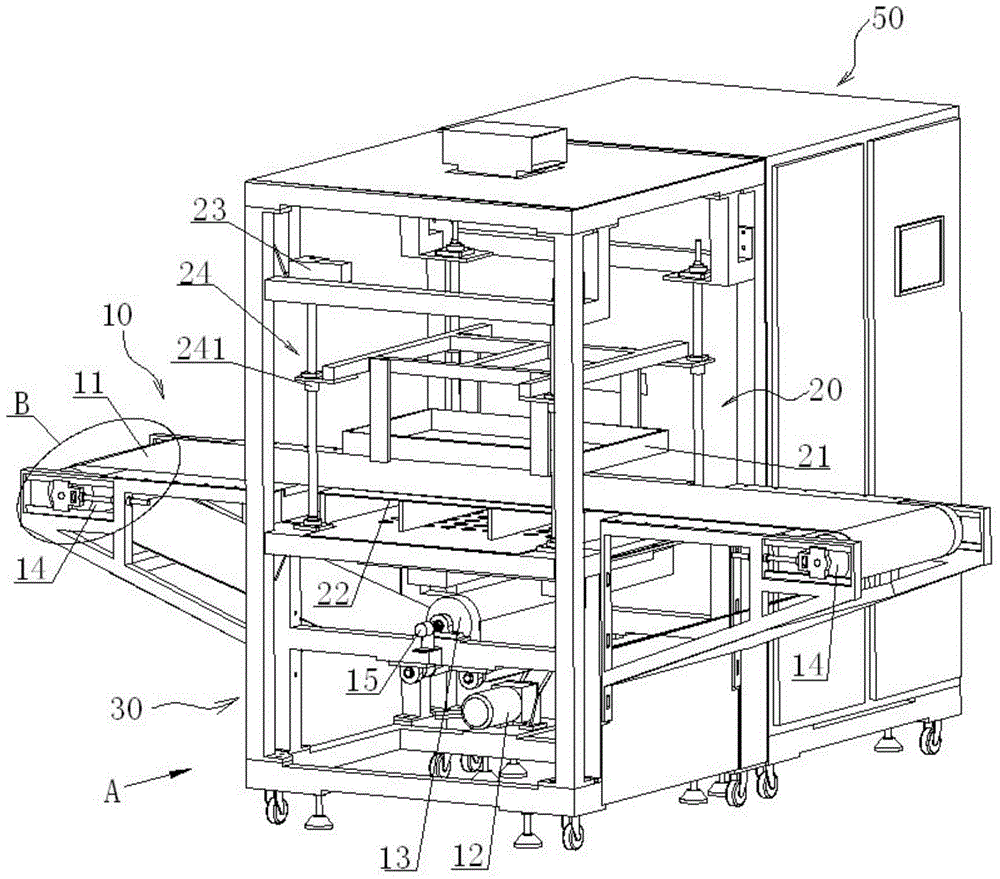

[0026] Figure 1~6 It schematically shows a radio frequency insecticidal and sterilizing continuous treatment device according to an embodiment of the present invention.

[0027] like figure 1 and figure 2 As shown, the radio frequency insecticidal and sterilizing continuous processing device includes a conveying device 10 , a radio frequency device 20 , a frame 30 and a control box 50 for controlling the conveying device 10 and the radio frequency device 20 . The frame 30 is covered with a casing 40 , and a ventilation hole 41 is opened on the top of the casing 40 , the radio frequency device 20 is located in the casing 40 , and the delivery device 10 penetrates the casing 40 .

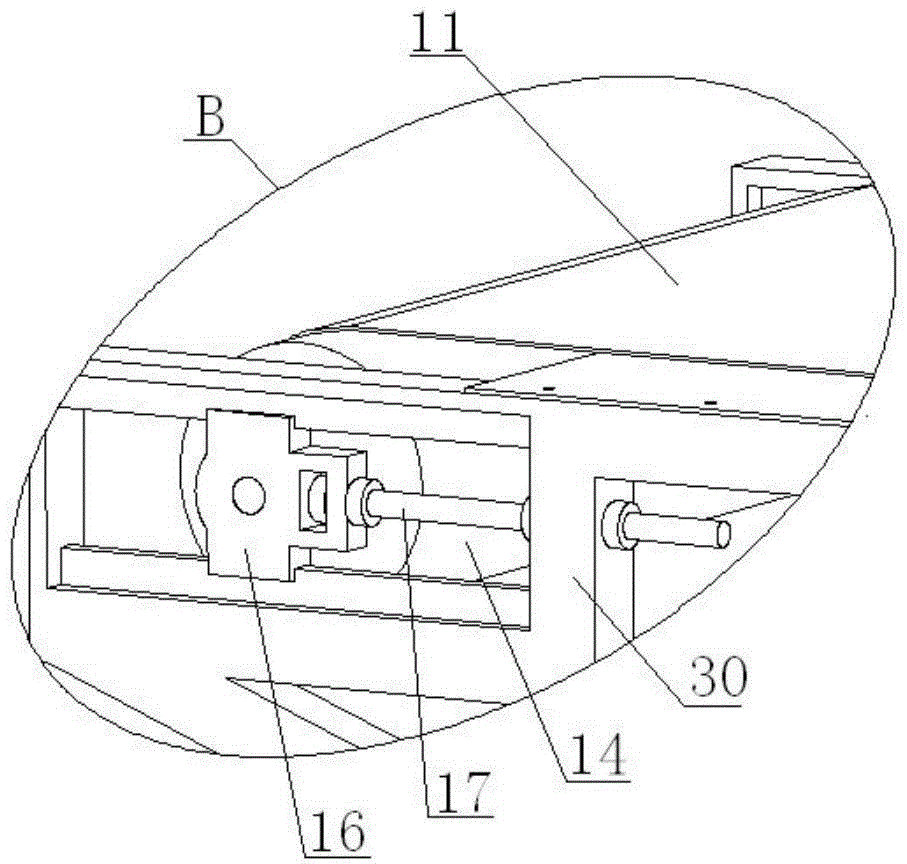

[0028] The conveyor device 10 includes a conveyor belt 11 , a drive motor 12 , a drive roller 13 and two end rollers 14 . The driving motor 12 , the driving roller 13 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com