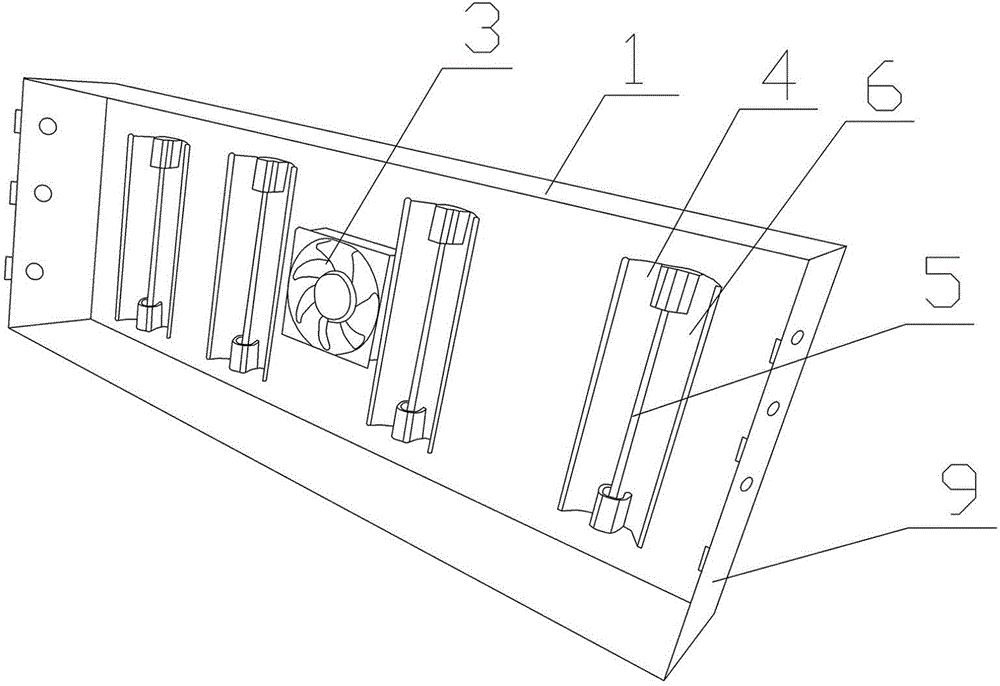

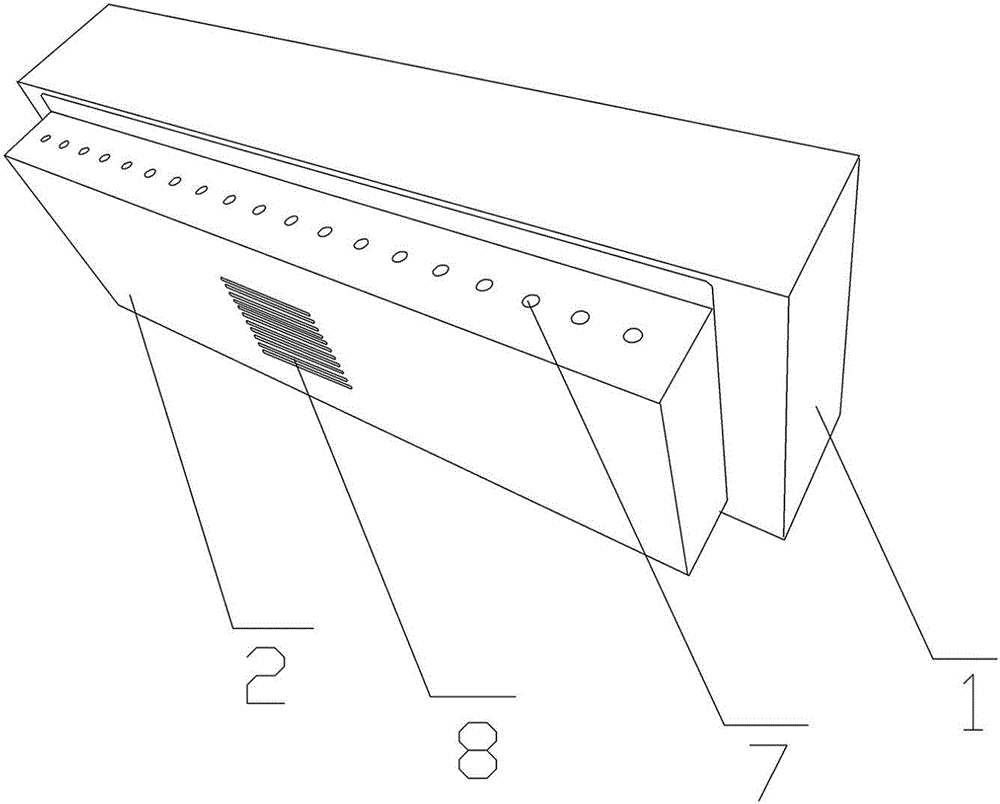

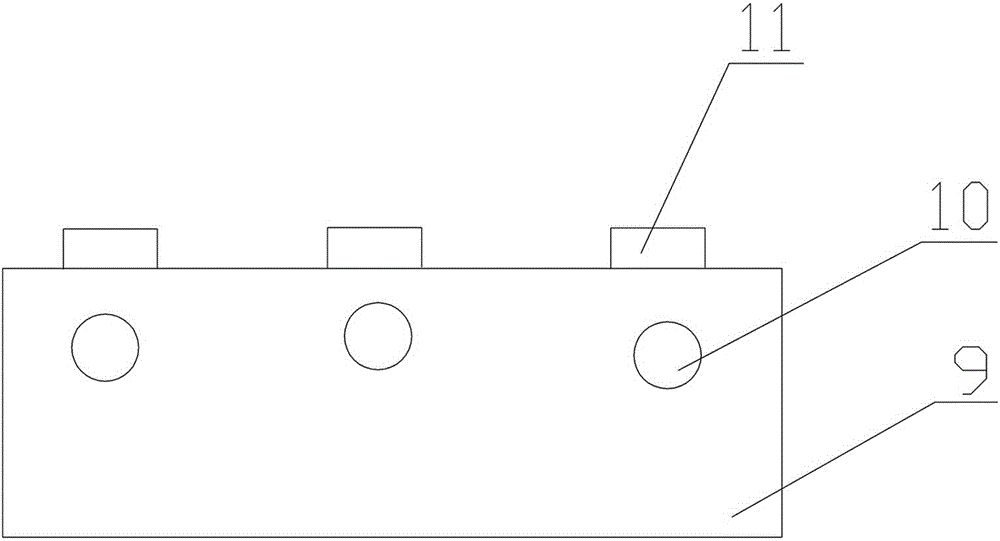

Pulsed light sterilizing device and sterilizing method

A sterilization device and pulsed light technology, applied in heating, irradiation and other directions, can solve the problem of small application range, achieve the effect of good sterilization effect, convenient disassembly and assembly, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The pulsed light sterilizing device of the present invention is applied to a sterilizing method for sterilizing the surface of tomatoes, which can perform preliminary sterilization on tomato raw materials, and reduce the initial number of colonies of microorganisms on the surface of tomatoes.

[0036] It is characterized in that the steps are as follows: a. The pulse light sterilizing device is installed at 30 cm above the surface of the conveying line, and the thickness of the tomato on the conveying line is a single layer; b. Exciting current makes the pulse light lamp work to generate pulse light, and the duration of a single pulse is 0.2 s, the tomato rolls under the pulsed light; c, the input voltage of the pulsed light tube after transformation is 1500V, and the pulse frequency is 20 times per minute.

[0037] Experimental method: use a sterile bag, randomly take whole tomato samples before pulse light sterilization as the first group, randomly take the whole tomat...

Embodiment 2

[0047] The pulsed light sterilizing device of the present invention is applied to the sterilization method of milk product packaging boxes, and can sterilize the milk product packaging boxes. The number of initial microbial colonies and heat-resistant bacillus are mainly used to assist the subsequent thermal sterilization process. .

[0048] It is characterized in that the steps are as follows: a. The pulse light sterilization device is installed 30 cm above the surface of the conveying line, and the thickness of the milk product packaging box on the conveying line is a single layer; b. Exciting current to make the pulse light lamp work, generating pulse light, single pulse The duration is 0.2s, and the dairy product packaging box passes under the pulsed light; c. After the voltage is transformed, the voltage input to the pulsed light tube is 2000V, and the pulse frequency is 30 times per minute.

Embodiment 3

[0050] The pulsed light sterilization device of the present invention is applied to the sterilization method of tofu stalls and cooked food stalls in the market, can sterilize the tofu stalls and cooked food stalls, and effectively reduce the number of microbial colonies such as yeast-based bacteria.

[0051] It is characterized in that the steps are as follows: a. The pulse light sterilization device is placed 20cm above the surface of the booth; b. Excitation current makes the pulse light lamp work to generate pulse light, and the duration of a single pulse is 0.2s; c. Input pulse after voltage transformation The voltage of the light tube is 1200V, and the pulse frequency is 15 times per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com