Bending machine for rolled panel

A technology for bending machines and plates, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as cracking, plate damage, performance degradation, etc., and achieve improved production efficiency, improved stress properties, and improved production environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

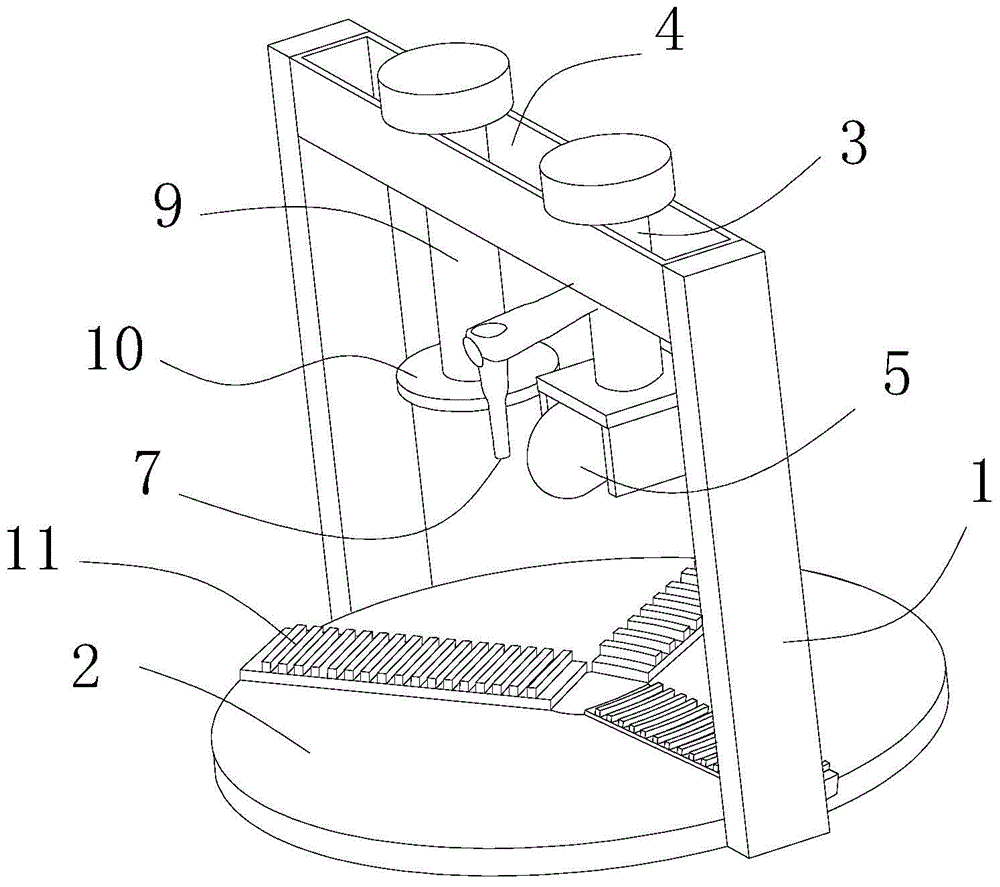

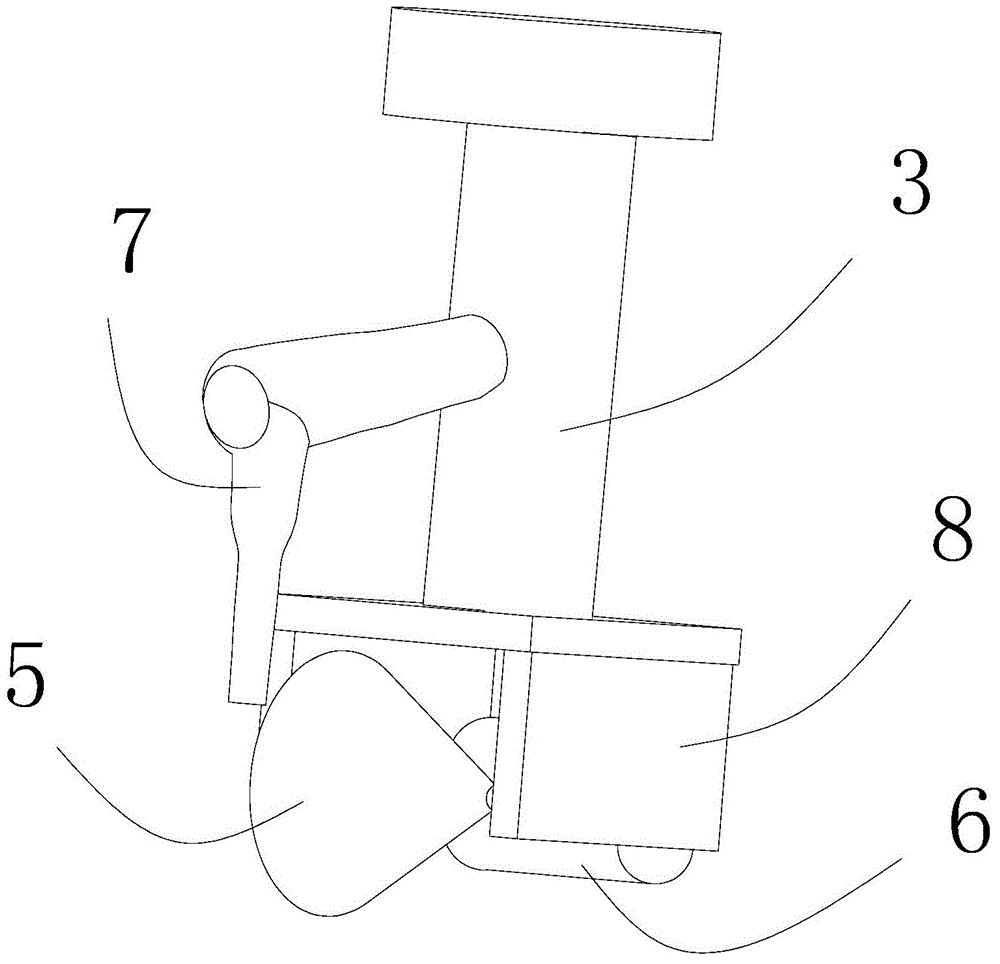

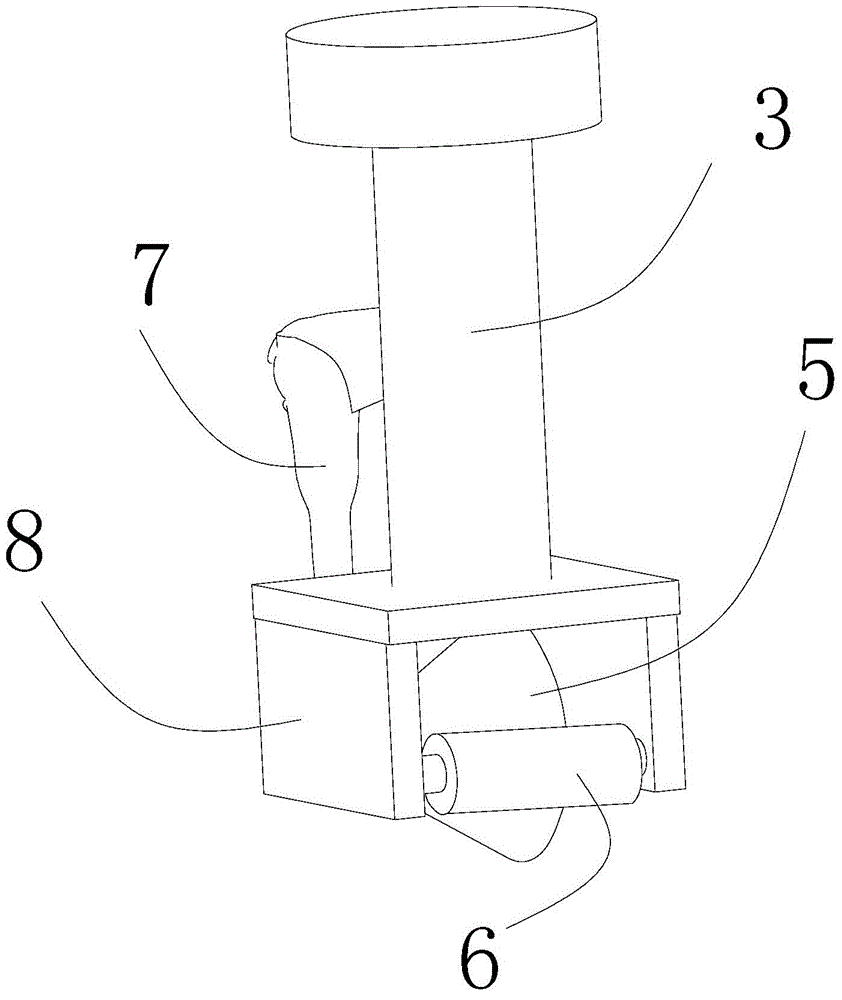

[0029] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0030] like Figure 1 to Figure 6 As shown, a coil plate bending machine includes a frame 1, the lower end of the frame 1 is provided with a rotatable chassis 2, and the upper end of the frame 1 is connected to a first slide bar 3 that can move horizontally. The upper end of the rod 3 is movably connected to the frame 1; the lower end of the first sliding rod 3 is provided with a conical pressure roller 5 for bending the end edge of the rolled plate 13, and the conical pressure roller 5 is horizontally rolled and arranged on the The lower end of the first slide bar 3; the tapered pressure roller 5 moves along the central axis direction, and the horizontal moving track of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com