Testing device and testing method for repeated positioning accuracy of servo tool holder

A repeat positioning accuracy and testing device technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of difficulty, time-consuming adjustment process, and difficulty in finding measuring points, etc., to achieve simple structure, The effect of simple test method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

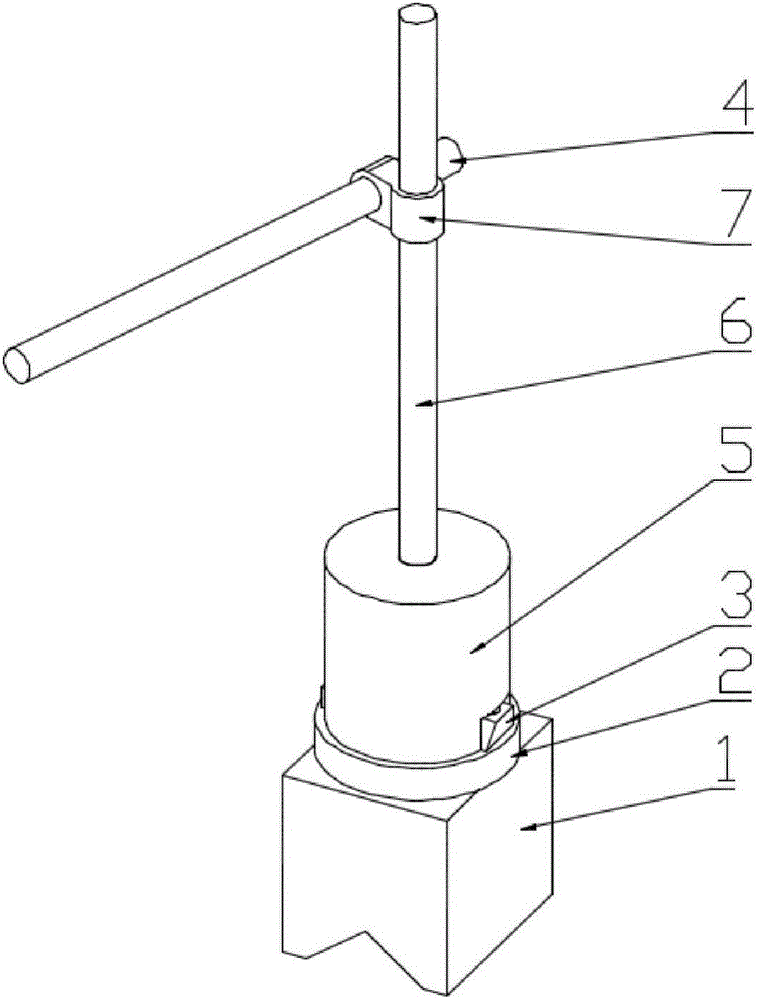

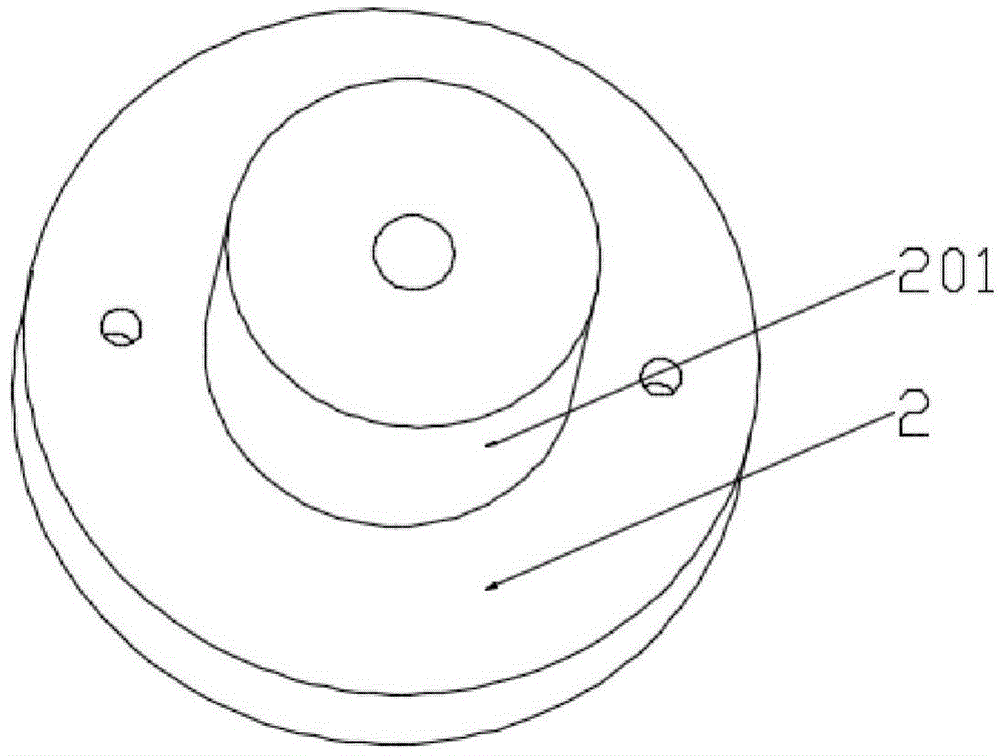

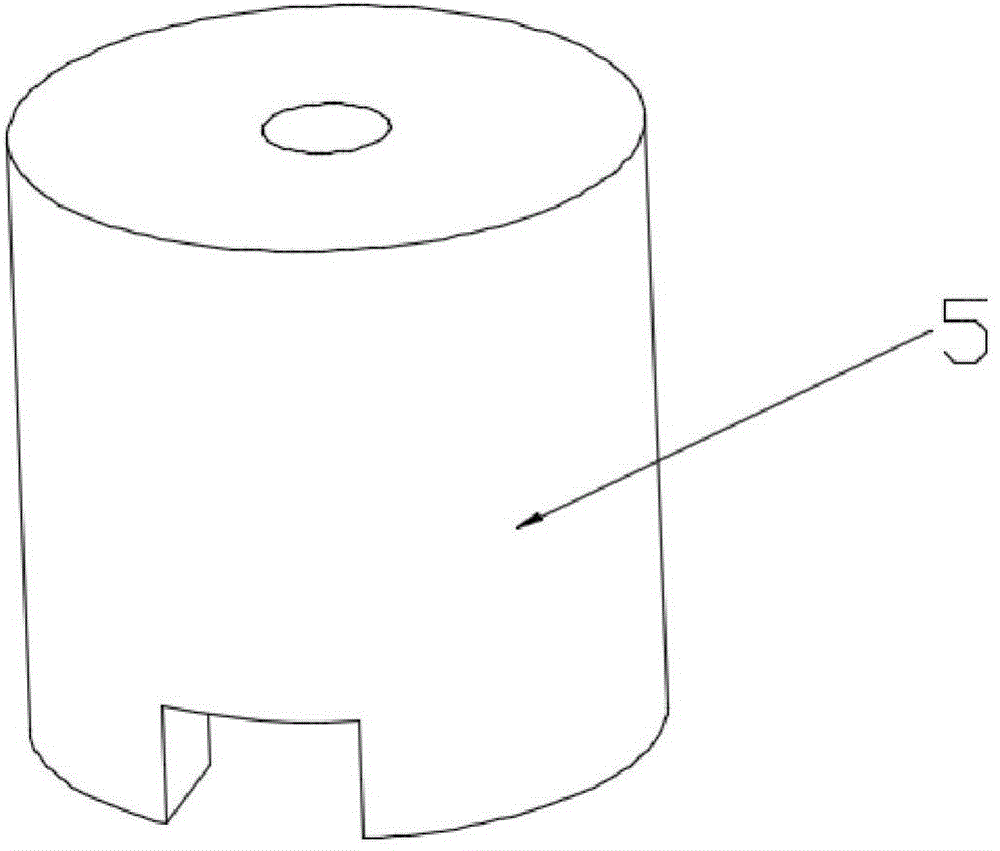

[0028] Such as Figure 1 to Figure 6 As shown, a test device for repeat positioning accuracy of a servo tool post according to the present invention includes a magnetic base 1, a positioning member 2 with a boss 201 on the upper part, a wedge block 3, a hollow rotating seat 5 and a rod assembly. The positioning part 2 is fixedly connected to the magnetic base 1 , and the wedge block 3 is fixedly connected to the positioning part 2 and is located outside the boss 201 . Along the circumferential direction of the positioning member 2, one end of the wedge block 3 is an inclined plane, and the other end is a vertical plane. The swivel seat 5 is sleeved on the boss 201 , and a notch is provided on the lower part of the wall of the swivel seat 5 , and the notch is matched with the wedge block 3 . The rod assembly is fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com