A non-contact removal device for the electro-corrosion layer at the bottom of the thin rib of the flexible joint

A flexible joint, non-contact technology, applied in the grinding and polishing field of machining, can solve problems such as affecting the performance of flexible joints, inability to remove the electro-erosion layer, etc., to reduce processing costs, reduce tool setting accuracy, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

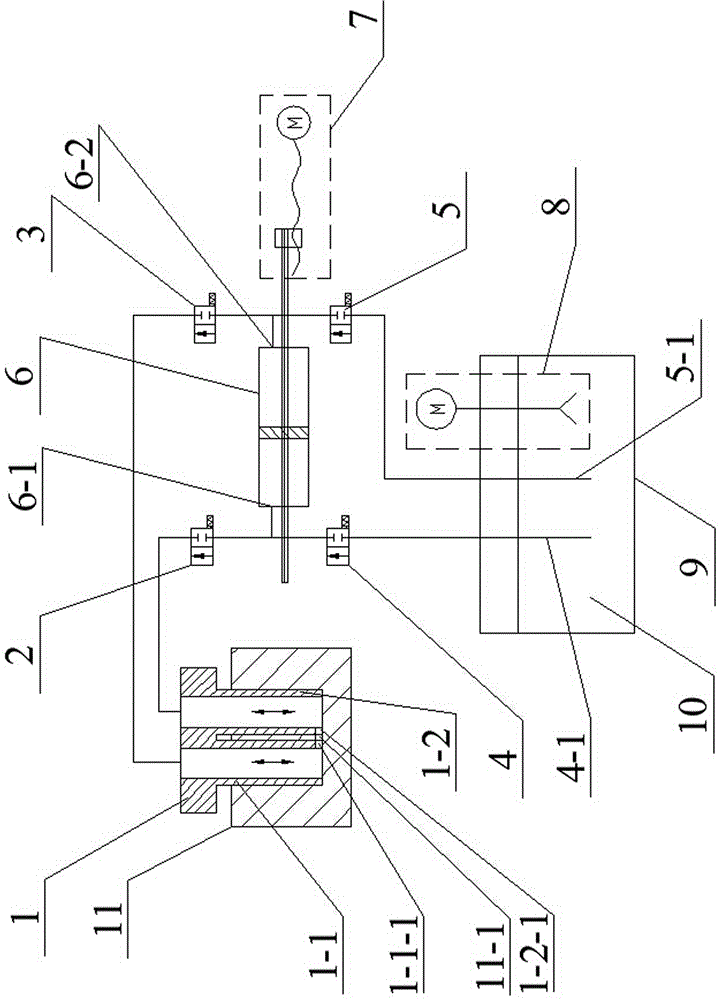

[0013] Specific implementation mode one: combine figure 1 As shown, it includes abrasive flow injection plug 1, first electromagnetic switch valve 2, second electromagnetic switch valve 3, third electromagnetic switch valve 4, fourth electromagnetic switch valve 5, piston cylinder assembly 6, reciprocating mechanism assembly 7 , stirring assembly 8, container tank 9, fluid abrasive processing fluid 10;

[0014] The front end of the abrasive flow injection plug 1 is provided with two first round tubes 1-1 and second round tubes 1-2 for respectively sealing and inserting into the paired holes of the flexible joint 11. The first round tube 1-1 There is a notch groove 1-1-1 on the port of the second circular tube 1-2, and there is a notch groove 1-2-1 on the port of the second round tube 1-2. When the two round pipes 1-2 are respectively inserted into the paired holes of the flexible joint 11, the notch groove 1-1-1 on the first round pipe 1-1 and the notch groove 1-2 on the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com