Device for supplying abrasive powder liquid to milling disc of grinding miller

A grinding machine and powder grinding technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of lack of phase burning, time-consuming and labor-intensive, overheating burning, etc., to reduce the probability of electrical accidents, liquid supply process The effect of safe, efficient and convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

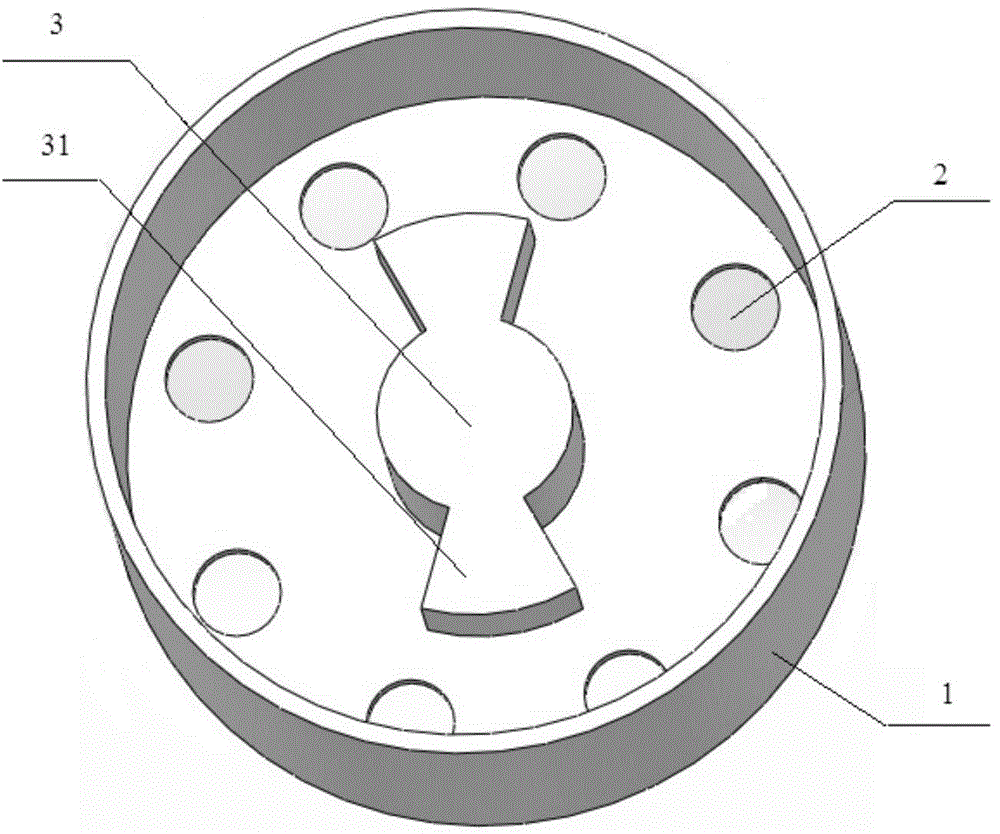

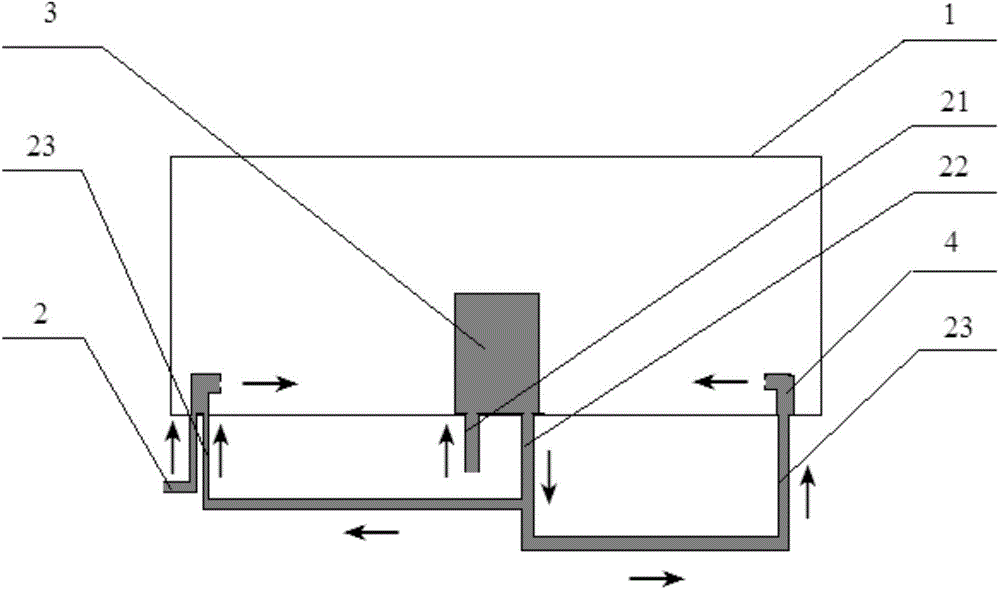

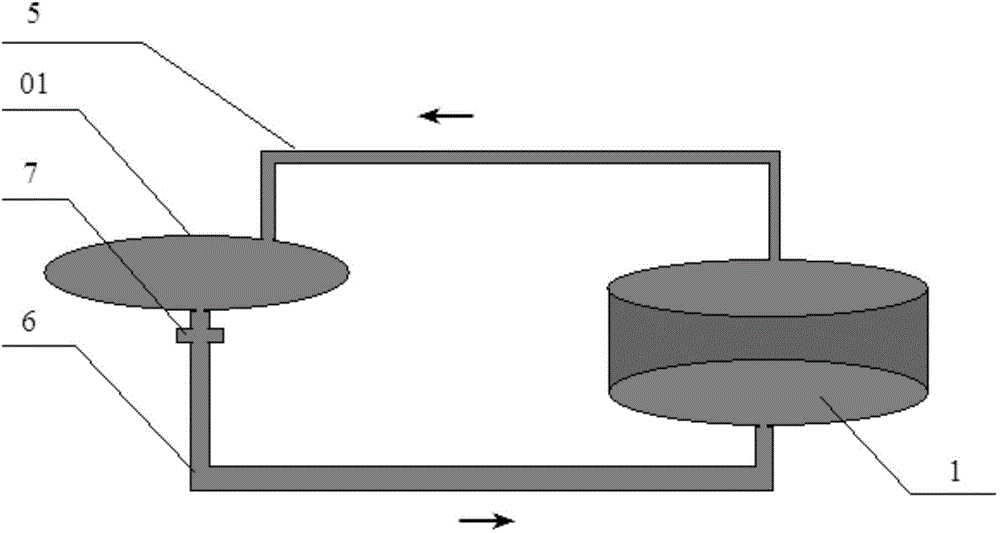

[0020] The invention provides a device for supplying grinding liquid to the grinding disc on the grinder, the device comprises a grinding barrel with openings for containing grinding liquid, which is arranged at the opening and is used for supplying the grinding liquid to the The pipeline for supplying air to the device and the pneumatic stirring parts used for rotating and stirring the milling liquid in the milling barrel. The pneumatic stirring component includes a pneumatic rotor and a stirring paddle connected to the pneumatic rotor and arranged in the milling barrel, and the pneumatic rotor is arranged in the center of the bottom of the milling barrel. The pneumatic stirring component also includes two or more air nozzles, and the air nozzles are arranged on different openings. The high-pressure air enters the device through the rotor inlet pipe, is discharged from the rotor exhaust pipe, and then enters the grinding barrel through the air nozzle inlet pipe.

[0021] Tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com