Double line rectification method of hexafluoropropene production cracking gas, and rectification apparatus thereof

A technology of hexafluoropropylene and cracked gas, applied in the field of rectification, can solve the problems of product purity not meeting requirements, low equipment utilization rate, leakage of highly toxic substances, etc., achieving high safety and environmental protection benefits, improving equipment utilization efficiency, and improving The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

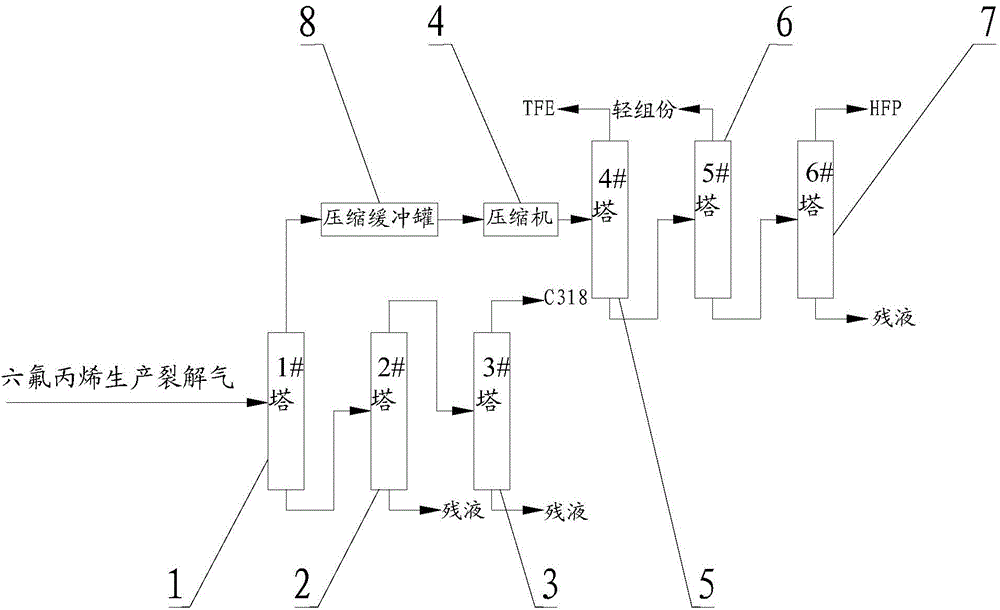

[0027] The cracked gas from the production of hexafluoropropylene is fed into the high boiler removal tower 1 for preliminary separation of light and heavy components. and the light component take the following two lines respectively:

[0028] 1. Heavy component (including C 4 f 8 and other highly toxic components) are separated from the tower still of the high boiler removal tower 1, and then carry out raffinate separation and C318 rectification tower 3 through the raffinate separation tower 3 to carry out C318 rectification, and the pressure of the raffinate separation tower 2 is 0.2 ~0.4MPa, the temperature is 30~60°C, the pressure of the C318 rectification tower 3 is 0.1~0.3MPa, the temperature is 20~30°C, and the octafluorocyclobutane with a purity greater than 99.8% is obtained;

[0029]2. Light components (including low-toxic components such as TFE and HFP) are separated from the top of the 1# tower, and enter the compressor 4 through the compression buffer tank 8, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com