Powder low temperature dry distillation gasification device

A gasification device, low-temperature technology, applied in the field of powder low-temperature dry distillation gasification device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

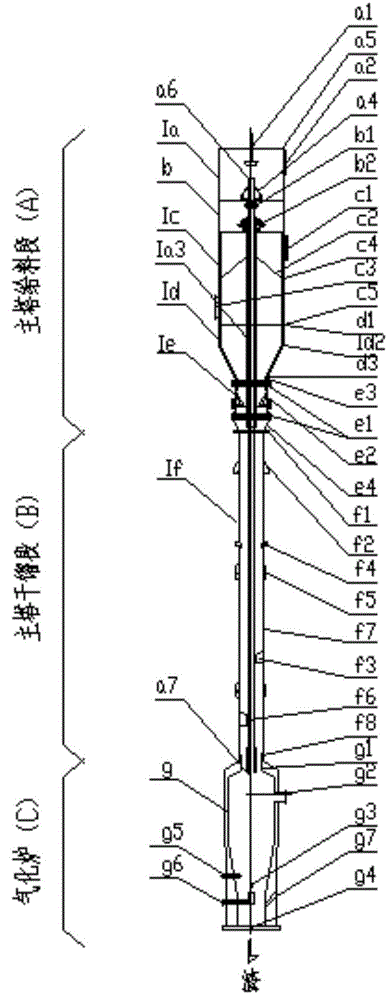

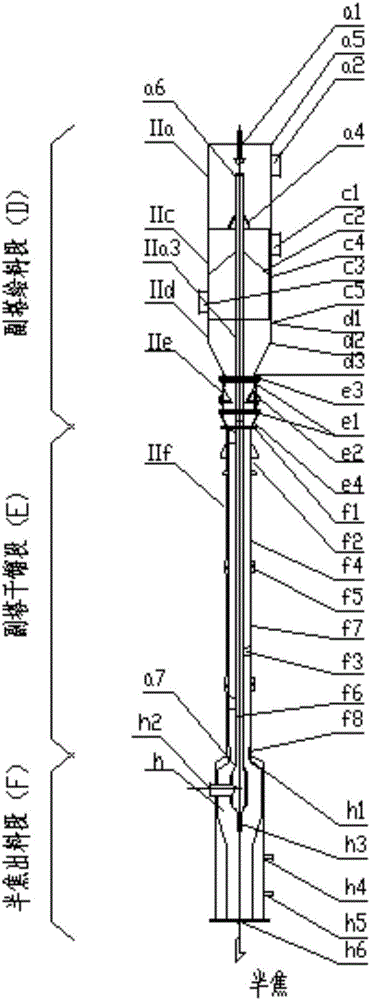

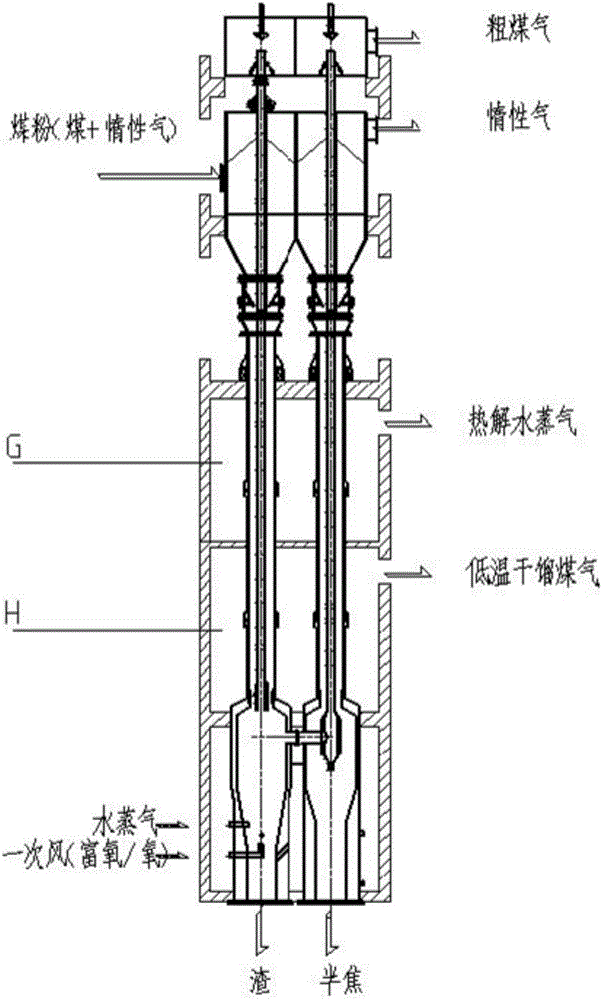

[0055] Specific implementation scheme two, for the purpose of producing gasified coal gas, the device combination of this scheme is the main tower and the main tower, see the attached Figure 4 .

[0056] in the attached Figure 4 As shown, the figure shows a combination schematic diagram of the main tower and the main tower of the powder low-temperature carbonization gasification device of the present invention. The main towers are arranged side by side with the main towers, and the top air collection chamber a and the feed bin c of the four main towers are connected to each other. A pyrolysis water vapor chamber G and a low-temperature carbonization gas chamber H are installed in the dry distillation section of the main tower.

[0057] The powder is transported into the powder inlet c3 of the four main tower feeding chambers Ic by dense-phase air flow of inert gas, and the material and gas are separated by the bag filter c2, and the gas is discharged through the inert gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com