A method for heat treatment of pipe screen welds

A technology of tube panels and fittings, applied in the field of heat treatment, which can solve problems affecting the quality of heat treatment of welded joints, difficulties in heat treatment methods, and large residual stress in tissues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The main chemical components of T92 alloy steel pipe fittings are shown in Table 1.

[0047] Table 1

[0048]

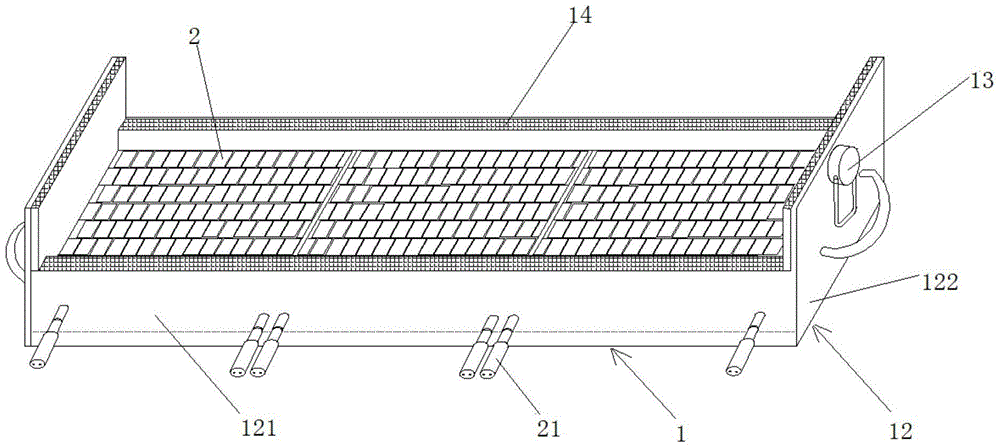

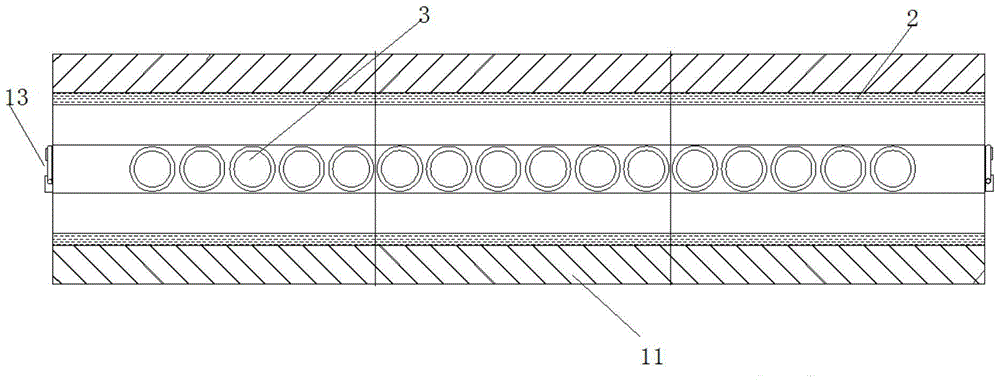

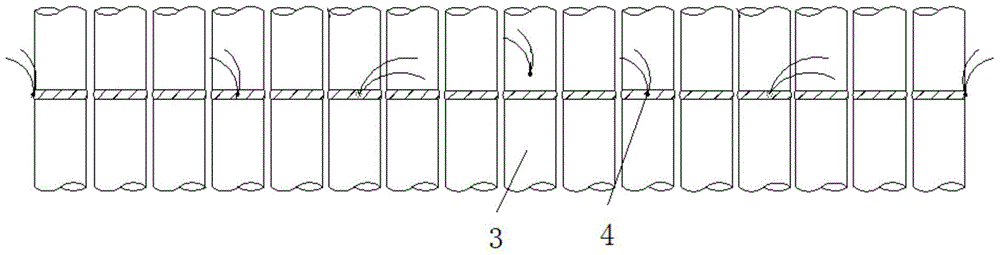

[0049] The pipe wall thickness is 7mm, the pipe diameter is 50mm, the welding seam width is 6mm, the heating box length is 1100mm, the width is 250mm, the number of pipes is 16, the center line position is 2cm above the welding seam, and the insulation layer thickness on the bottom plate 11 of the heating box 1 50mm, the thickness of the insulation layer pressed on the side plate 12 of the tube panel 3 is 150mm; the total power of the heating device is 20kw.

[0050] The heat treatment process is: heat treatment heating temperature 760±10℃, constant temperature time 120h, lifting rate 150℃ / h, when the temperature is below 300℃, the heating speed may not be controlled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com