Anti-static yarn-dyed fabric

An antistatic and antistatic agent technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of large process loss, high output of white gray cloth, static electricity, etc., and achieve good antistatic performance and low volume specific resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

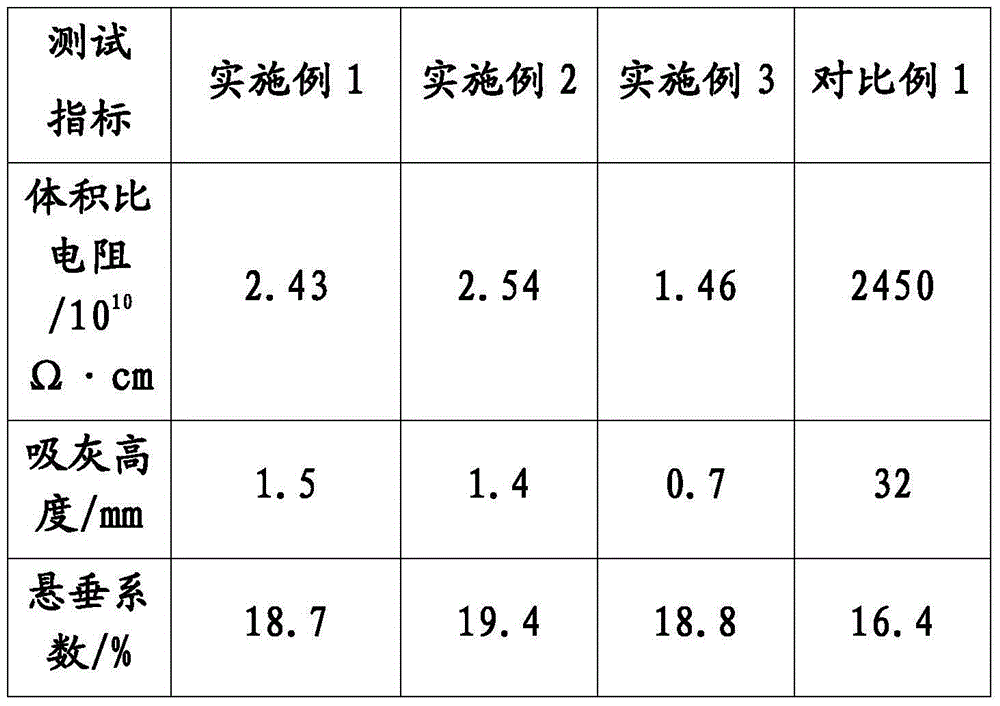

Embodiment 1

[0016] This embodiment provides an antistatic yarn-dyed fabric, which is 150D*200D polyester yarn-dyed fabric and weighs 100 g. The composition of the antistatic coating is: 0.5g epoxy resin, 1g octadecyltrimethylammonium. The preparation method is: pre-mix the two components of the antistatic coating, and then paddle on the yarn-dyed fabric at room temperature. The excess rolling rate is 100%, pre-baked at 80°C and baked at 140°C to obtain antistatic yarn-dyed fabric.

Embodiment 2

[0018] This embodiment provides an antistatic yarn-dyed fabric, which is 150D*200D polyester yarn-dyed fabric and weighs 100g. The antistatic coating is composed of: 1g epoxy resin, 2 octadecyltrimethylammonium, and the preparation method is: pre-mix the two components of the antistatic coating, and then paddle on the yarn-dyed fabric at room temperature, and roll The residual rate is 100%, pre-baked at 70°C, and baked at 130°C to obtain antistatic yarn-dyed fabric.

Embodiment 3

[0020] This embodiment provides an antistatic yarn-dyed fabric, which is 150D*200D polyester yarn-dyed fabric and weighs 100 g. The composition of the antistatic coating is: 1.5g epoxy resin, 1.5g octadecyltrimethylammonium. The preparation method is: pre-mix the two components of the antistatic coating, and then pad and roll on the yarn-dyed fabric at room temperature , the excess rolling rate is 100%, pre-baked at 90°C, and baked at 135°C to obtain antistatic yarn-dyed fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com