Steel pipe column concrete pumping and jacking forming matching system

A technology for concrete pumps and steel pipe columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems that the design value of concrete strength cannot be guaranteed, the common problems of concrete not dense and quality, and the use of space for high-altitude work is small, and the application effect is remarkable. Reasonable layout design and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

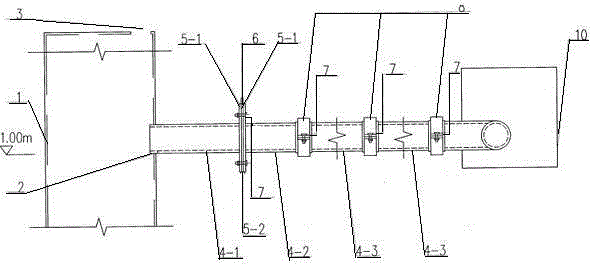

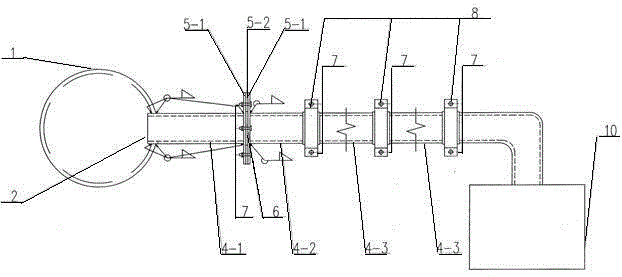

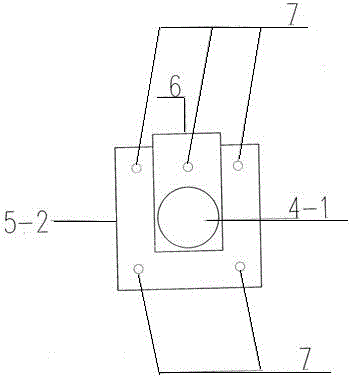

[0016] Such as Figure 1-Figure 4 As shown, a steel pipe column concrete pumping jacking forming supporting system includes a steel pipe column 1, high-pressure pump pipes 4-1, 4-2, 4-3, attached plates 5-1, 5-2, and a stop valve 6. High-strength bolts 7, flange clamps 8 and vehicle-mounted ground pump 10; wherein high-pressure pump pipes 4-1, 4-2, stop valve 6, attached plates 5-1, 5-2 and high-strength bolts 7 form a movable throat assembly.

[0017] One side of the steel pipe column 1 is provided with an opening pressure injection port 2, and the top of the steel pipe column 1 is provided with an air outlet 3; Attached plates 5-1, 5-2 are fixedly connected respectively, and pass through the stop valve 6 placed between the two attached plates 5-1, 5-1 and another atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com