Method for blocking gas extraction boreholes with coal and rock debris as borehole sealing material

A technology for gas drainage and sealing materials, which is applied in the direction of gas discharge, sealing/seal, mining equipment, etc. It can solve the problems of incomplete sealing, cumbersome batching operations, and cost, so as to avoid waste of resources and simplify sealing The effect of plugging operation and simplification of hole sealing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

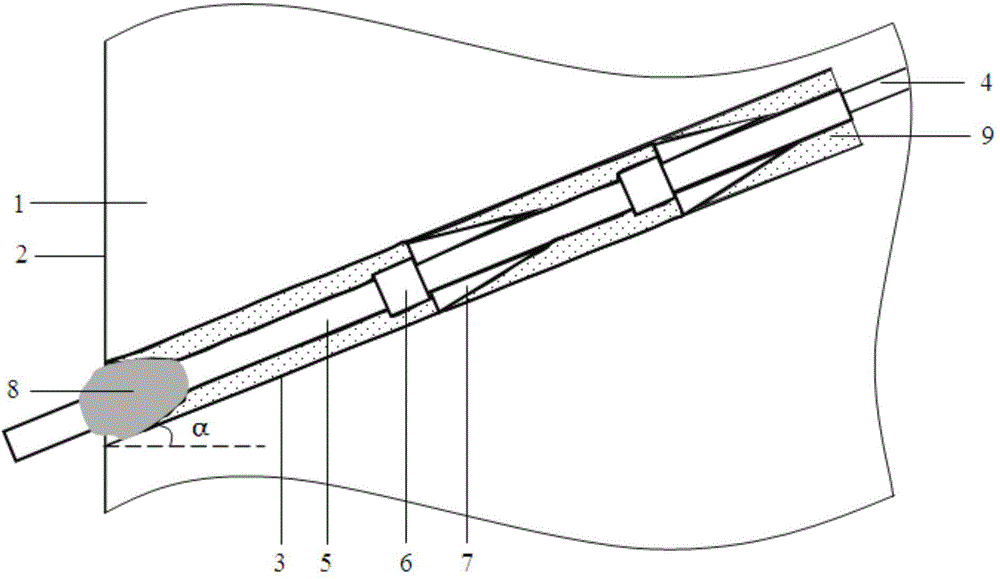

[0024] In this embodiment, the schematic diagram of plugging the gas drainage borehole is shown in figure 1 , the total length of the gas drainage boreholes is 38m, in which the length of the primary borehole 3 is 12m, the included angle (elevation angle) α between the primary borehole and the horizontal plane is 60°, and the hole diameter is about 120mm. 4 has a length of 26m and a diameter of approximately 75mm.

[0025] (1) According to the actual engineering needs, it is determined that the coal seam that needs gas control is determined, and a drilling machine is installed in the coal seam bottom pumping roadway of the coal seam, and a drill bit with a diameter of 113mm and a drill pipe with a diameter of 50mm are used. A first-level borehole 3 is drilled on the coal rock mass 1 .

[0026] (2) Connect three gas drainage pipes 5 with an outer diameter of 85mm and an inner diameter of 75mm with joint sleeves 6 and adhesives. After the connection, the total length is 13.5m. ...

Embodiment 2

[0029] In this embodiment, the total length of the gas drainage boreholes is 35m, wherein the length of the primary borehole 3 is 8m, the included angle (elevation angle) α between the primary borehole and the horizontal plane is 30°, and the aperture is about 120mm. The secondary borehole 4 has a length of 27m and a diameter of about 75mm.

[0030](1) According to the actual engineering needs, it is determined that the coal seam that needs gas control is determined, and a drilling machine is installed in the coal seam bottom pumping roadway of the coal seam, and a drill bit with a diameter of 113mm and a drill pipe with a diameter of 50mm are used. A first-level borehole 3 is drilled on the coal rock mass 1 .

[0031] (2) Connect three gas drainage pipes 5 with an outer diameter of 85mm and an inner diameter of 75mm with joint sleeves 6 and adhesives. After the connection, the total length is 9m. Three wooden wedges 7 are fixed with steel wires at the joints of the pipes, an...

Embodiment 3

[0034] In this embodiment, the total length of the gas drainage borehole is 36m, wherein the length of the primary borehole 3 is 11m, the angle (elevation angle) α between the primary borehole and the horizontal plane is 80°, and the aperture is about 120mm. The secondary borehole 4 has a length of 25m and a diameter of about 75mm.

[0035] (1) According to the actual engineering needs, it is determined that the coal seam that needs gas control is determined, and a drilling machine is installed in the coal seam bottom pumping roadway of the coal seam, and a drill bit with a diameter of 113mm and a drill pipe with a diameter of 50mm are used. A first-level borehole 3 is drilled on the coal rock mass 1 .

[0036] (2) Connect three gas drainage pipes 5 with an outer diameter of 85 mm and an inner diameter of 75 mm with joint sleeves 6 and adhesives. After the connection, the total length is 12 m. Two wooden wedges 7 are fixed with steel wires at the joints of the pipes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com