Engineering machine counterweight and manufacturing method thereof

A technology of construction machinery and balance weight, applied in the direction of balance weight, etc., can solve the problems of no solution, reduce the optional range of internal core materials, etc., and achieve the effect of reducing metal consumption, good market application value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

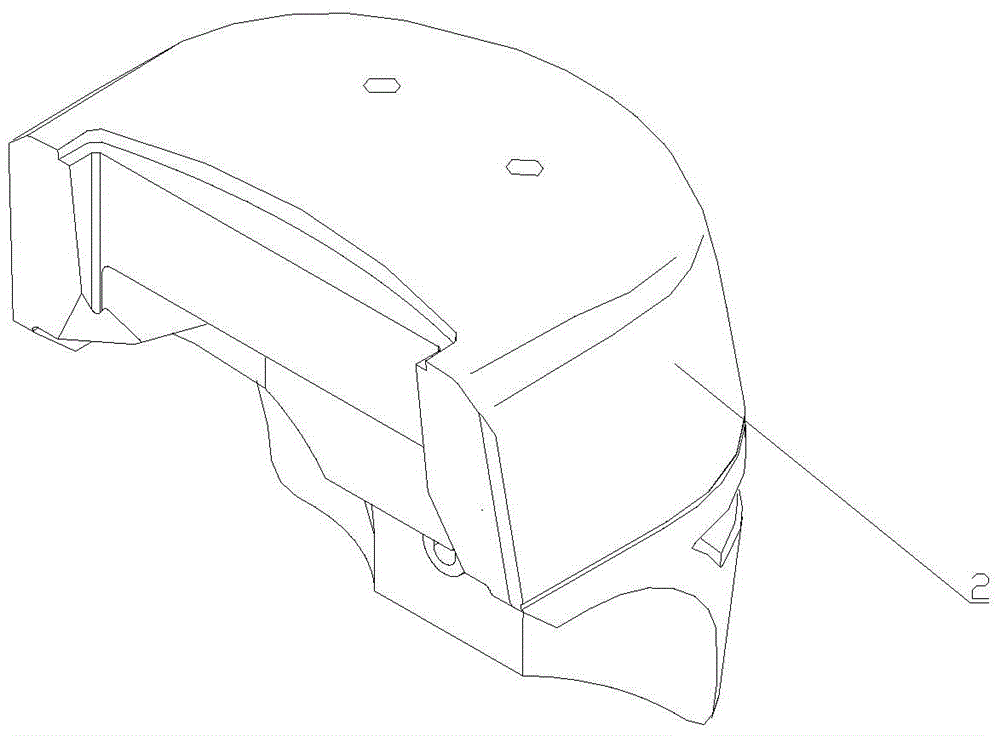

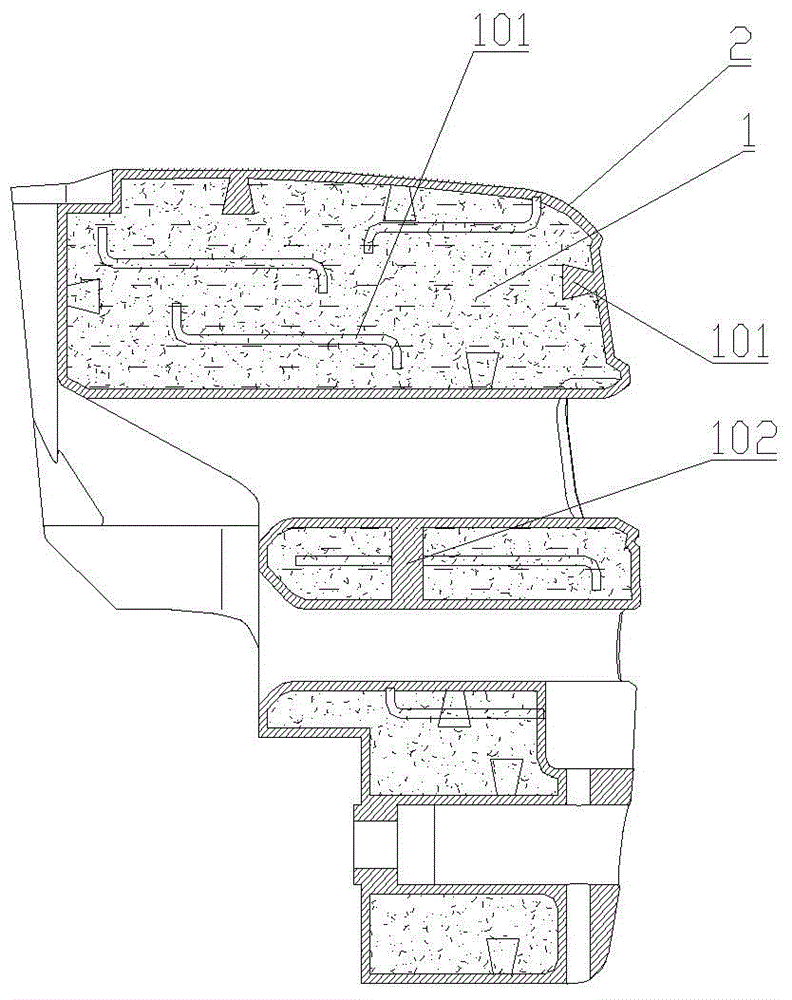

[0030] A balance weight for construction machinery, including an inner core material 1 and an outer casting material 2, the outer casting material 2 wraps the inner core material 1, the inner core material 1 includes a combined split body, and the combined split body is in order from bottom to top Combined into the inner material to be poured, the outer pouring material 2 is poured on the outside of the inner core material 1 to form a whole.

[0031] The outer surface of the inner core material 1 is provided with reserved grooves 101 or reserved holes 102 .

[0032] The external casting material 2 forms reinforcing ribs or reinforcing fixing columns at the reserved grooves 101 or reserved holes 102 .

[0033] The inner core material 1 includes metal, non-metal or metal and non-metal mixture, or metal, non-metal and cement, glass water and other binders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com