Tubular heat collecting evaporator and solar water heater with the heat collecting evaporator

A technology for solar water heaters and solar collector panels, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve the problems of low solar energy conversion efficiency, potential safety hazards, and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

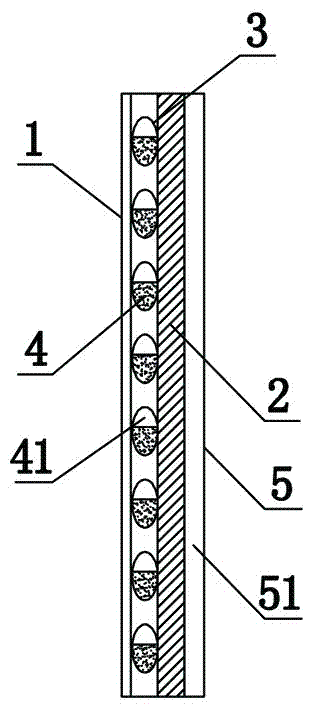

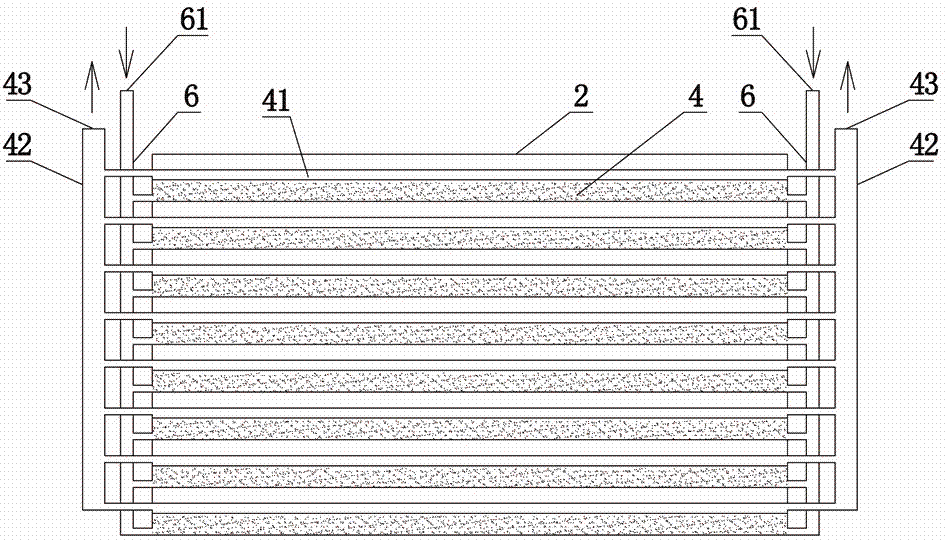

[0018] Such as figure 1 and figure 2 Shown, a kind of tubular heat collecting evaporator, it comprises heat-insulating shell 5, is arranged on the solar heat collecting plate 2 in described heat-preserving shell 5, a plurality of evaporation tubes 3 and cover is located on described solar heat collecting plate 2 A glass cover plate 1 is provided, and an insulating layer 51 is provided between the solar heat collecting plate 2 and the insulating shell 3 to prevent internal heat loss. A plurality of evaporating tubes 3 are arranged in parallel between the glass cover plate 1 and the solar heat collecting plate 2. In this embodiment, the evaporating tubes 3 are directly fixed on the solar heat collecting plate 2, which is convenient for income heat, and the evaporation tube 3 can be positioned to form a heat collecting evaporator with a flat structure. The bottom of the evaporation tube 3 is laid with a capillary structure layer 4, the upper layer of the evaporation tube 3 for...

Embodiment 2

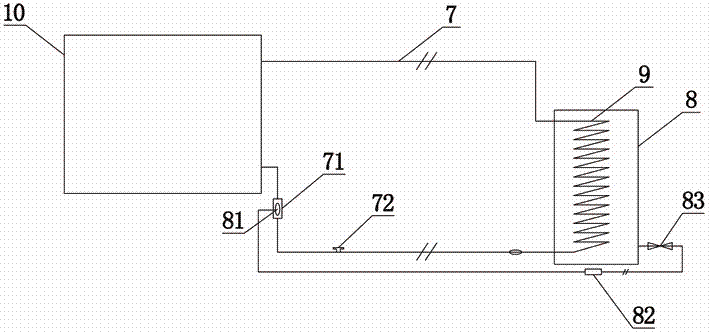

[0024] Such as image 3 As shown, a solar water heater includes a heat collecting evaporator 10, a water storage tank 8, a condenser 9 arranged in the water storage tank 8, and a loop pipeline 7, thereby forming a split solar water heater, which is suitable for middle and high-rise buildings building needs. The gas-phase outlet of the heat-collecting evaporator 10, the loop pipe 7, the inlet and outlet of the condenser 9 and the liquid-phase inlet of the heat-collecting evaporator 10 are sequentially connected to form a heat circulation delivery loop.

[0025] The heat-collecting evaporator 10 used in this embodiment is the flat-plate heat-collecting evaporator in the above-mentioned embodiment 1 or embodiment 2, and the circulation of the heat circulation delivery circuit can carry out the circulating delivery of the working medium without other power. Specific working principle: use the heat collecting evaporator 10 to absorb solar radiation, heat the liquid working medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com